Not Just Heat Exchangers: Complete Lines Drive HRS Business Growth

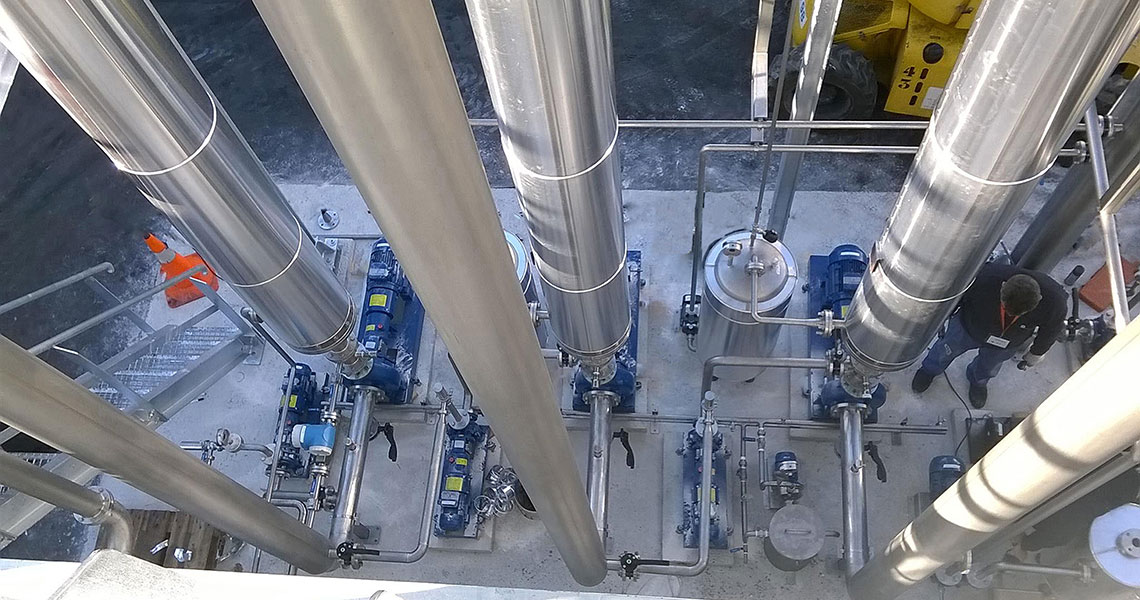

HRS is well known as a leading supplier of heat exchange, but our clients are increasingly looking for turnkey solutions for their thermal processing challenges. In response to this, HRS has a team solely dedicated …

Read More

Not Just Heat Exchangers: Complete Lines Drive HRS Business Growth

HRS is well known as a leading supplier of heat exchange, but our clients are increasingly looking for turnkey solutions for their thermal processing challenges. In response to this, HRS has a team solely dedicated …

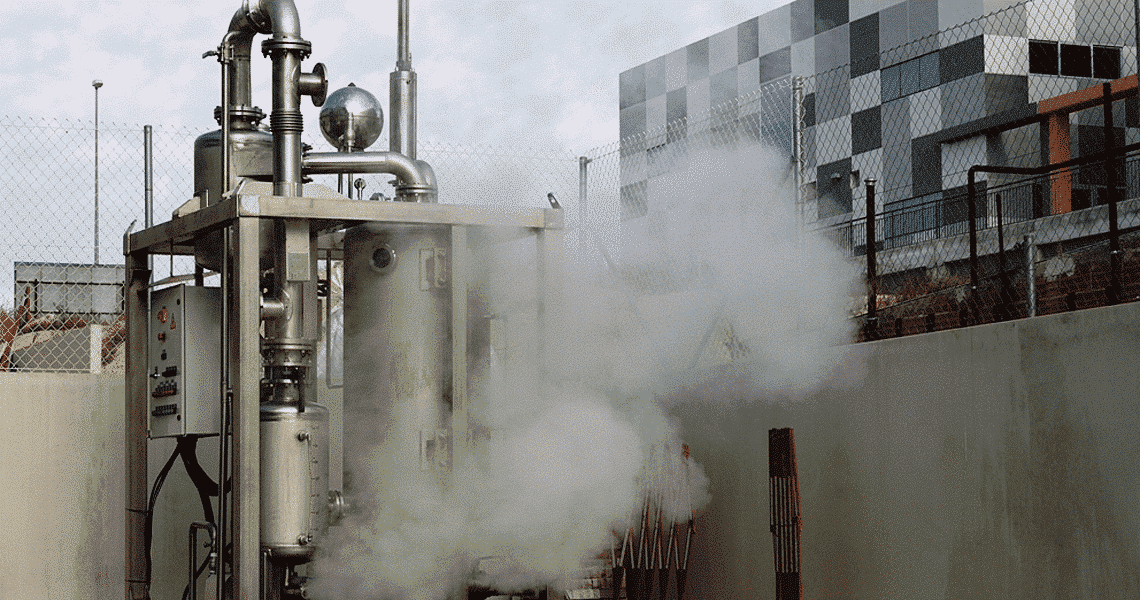

Read MoreHRS Heat Exchangers operate globally at the very forefront of thermal technology, offering innovative and effective heat transfer products. We believe strongly in offering a focus on managing energy efficiency across numerous sectors, including environmental, food and beverage, pharmaceutical and industrial.

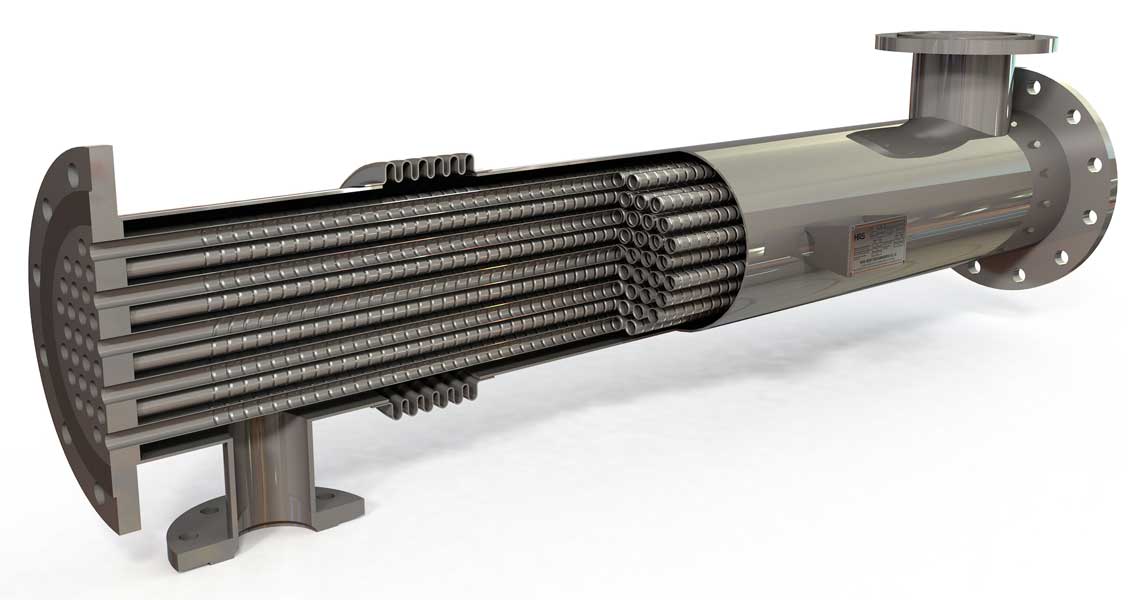

The HRS Group was established back in 1981 with the aim of operating at the pinnacle of thermal technology. For more than 40 years we’ve been producing products and systems used in a wide variety of process industries, such as chemicals, pharmaceuticals, and environmental protection among others, with a focus on difficult applications using our corrugated tube and patented scraped surface heat exchanger technologies.

Since our inception, we have continuously developed cutting-edge heat exchanger technologies, with a commitment to working closely with our partners and customers to deliver enhanced performance, reduce emissions and protect our environment.