HEAT EXCHANGERS

HRS Heat Exchangers operates globally and at the forefront of thermal technology, offering innovative and effective heat transfer products worldwide, with a strong focus on managing energy efficiently.

With over 40 years’ experience specialising in design and manufacture of an extensive range of corrugated tube and scraped surface heat exchangers, in compliance with the European Pressure Vessel Directive.

Our heat exchangers fall into three main categories:

Corrugated Tube Heat Exchangers

Using HRS’ corrugated tube technology, both heat transfer and efficiency are increased over standard smooth tube heat exchangers. In addition, potential fouling is minimised, making it possible to supply more compact and economical heat exchangers. HRS offers a wide product range, with models developed for various types of industries, manufactured from stainless steel. Bespoke designs and other materials are also available.

Advantages of Corrugated Heat Exchangers:

- Increased heat transfer

- Minimal fouling

- Reduced servicing costs

- Compact design

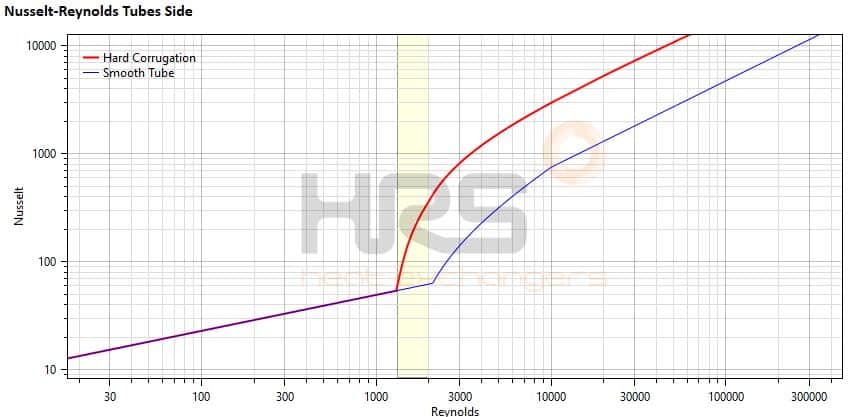

The Reynolds graph shows the increase of heat transfer using corrugated tube in comparison to smooth tube.

In this video, it demonstrates break the laminar flow and generate turbulence within the tubes.

HRS offers three types of corrugated tube heat exchangers:

Scraped Surface Heat Exchangers

For difficult heat transfer applications, with high viscosities and where fouling can become a problem, the preferred option is a scraped surface heat exchanger. The reciprocating or rotating movement of the scrapers mixes the fluid whilst cleaning the heat exchange surface. This keeps heat transfer high and reduces downtime. In addition, an increase in the turbulence increases the level of heat transfer.

HRS offers two technologies for scraped surface heat transfer: Unicus series which reciprocates and R series which rotates. Both of these patented solutions are designed for specific needs.

Plate Heat Exchangers

HRS plate heat exchangers are ideal for applications where the fluids have relatively low viscosity with no particles. They are also an ideal choice where product outlet temperature is close to the service inlet temperature.