Industrial Double Tube Heat Exchangers – HRS DTI Series

The HRS DTI Series is a complete stainless steel double tube heat exchanger designed for industrial applications.

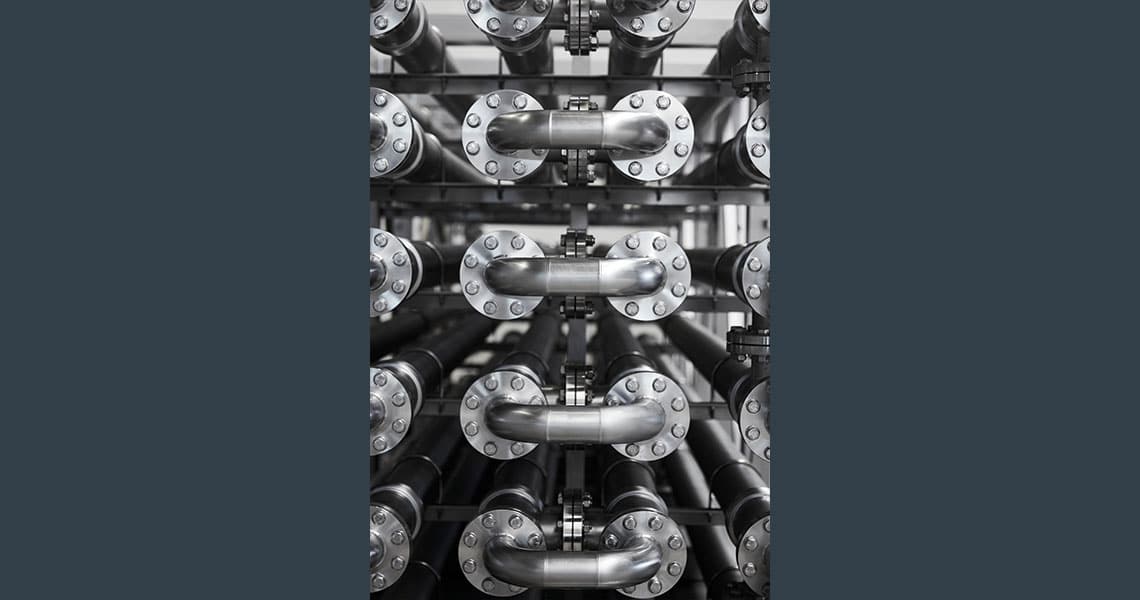

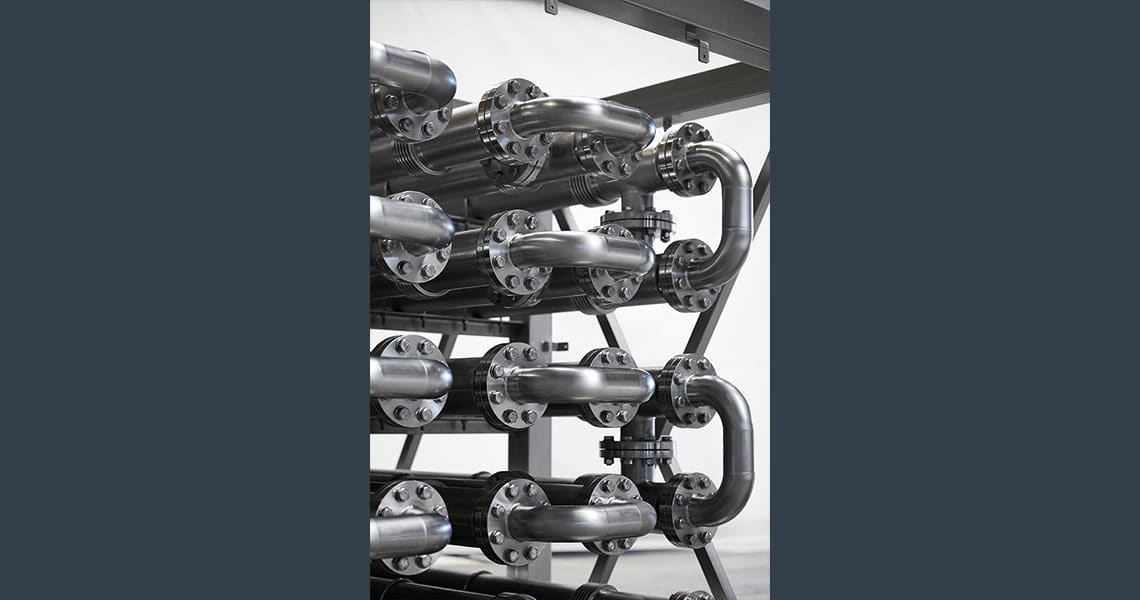

Because of its geometry the DTI Series is a true counter current heat exchanger; the product flows through the inner tube and the service fluid flows through the surrounding shell.

Using our corrugation technology, both heat transfer and efficiency are increased over standard smooth tube heat exchangers. In addition, potential fouling is minimised.

Expansion joint (bellows) is fitted in the shell to allow for differential expansion of the inner and outer tube during operation. Multiple units can be interconnected and have the options of frame mounting, insulated and cladded in stainless steel.

The HRS DTI series is suitable for applications with fluids containing fibres or particles and low-high viscosity fluids.

TECHNICAL DATA

Standard Materials of Construction:

- Service side: AISI 304 stainless steel

- Product side: AISI 316L stainless steel

Other material options available

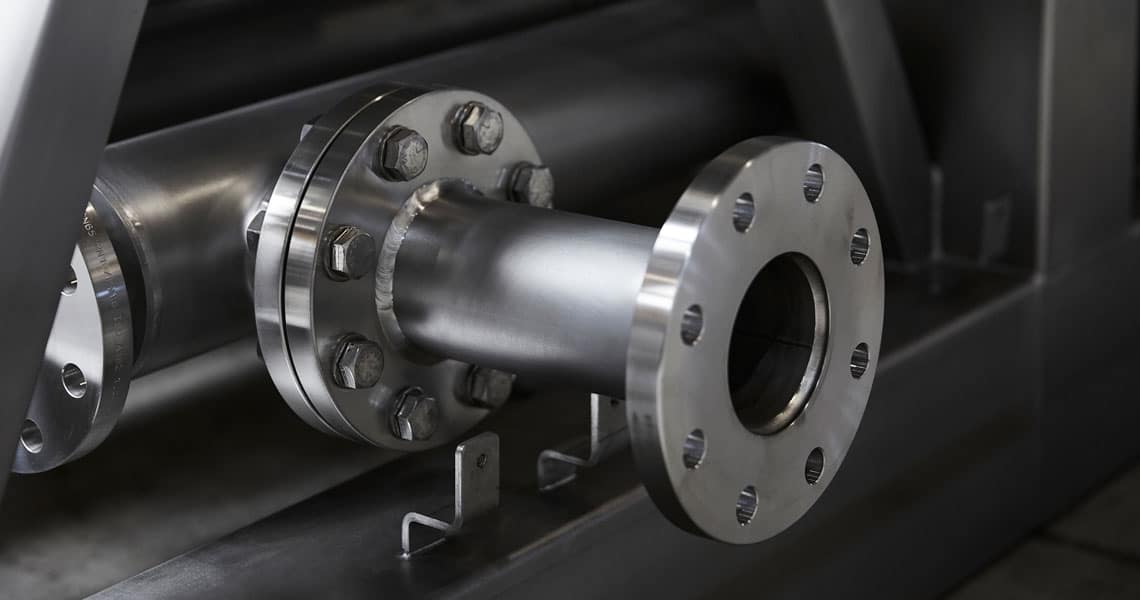

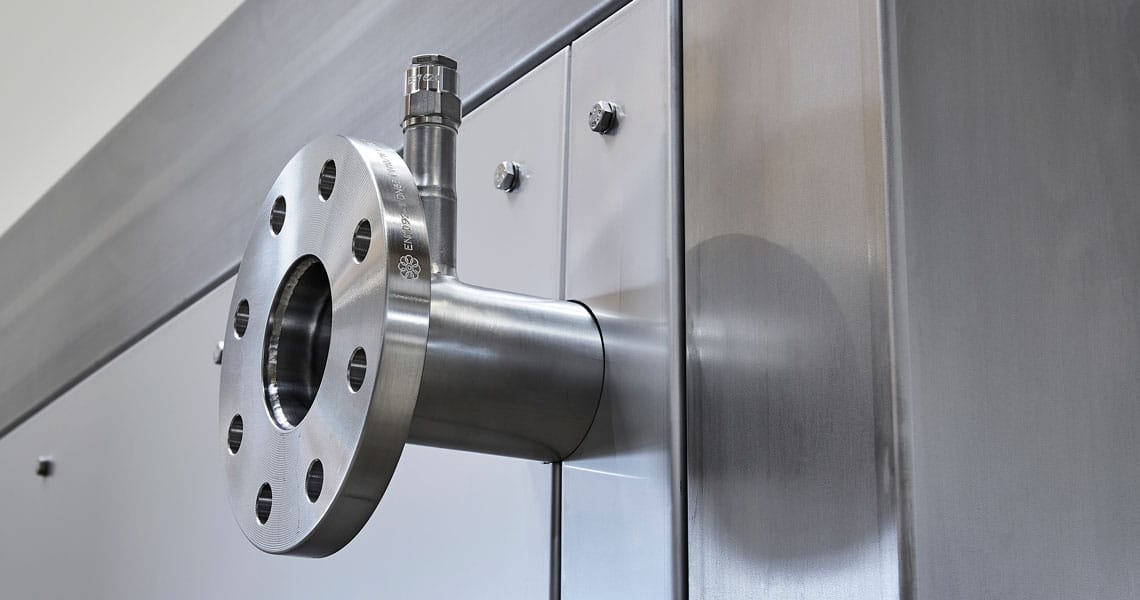

Standard Connections:

- Service side: Flange

- Product side: Flange

All flange types available

Surface Finish:

- External: Matt

- Internal: Matt

Design code and compliance:

- PD 5500, PED 2014/68/EU, ASME

- TR CU 032, DOSH Compliant