Wastewater Evaporation Plant

A chemical company in Spain that produces sulphuric acid, nitric acid and other chemicals approached us to resolve a serious environmental problem that they had involving the wash water used to clean the tanks where chemicals are stored.

Obviously no wash water could be drained to the river without being treated to eliminate all traces of hazardous chemicals.

Solution

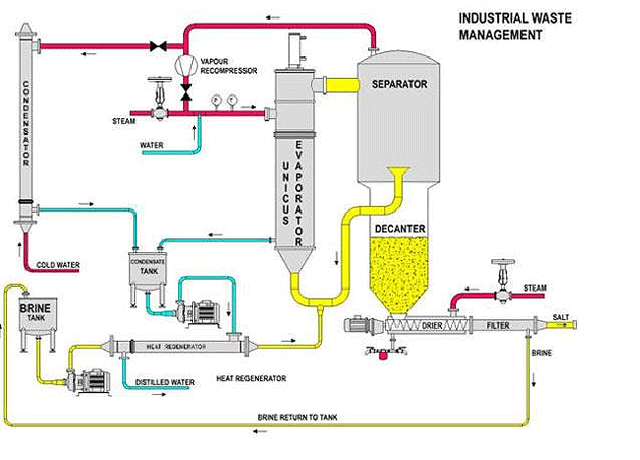

We proposed a solution designed to utilise a unique effect of evaporation and a mechanical vapour re-compression system to reduce energy consumption.

Evaporation is performed at 80°C, and the vapour obtained is compressed up to a pressure equivalent to 105°C approximately. This vapour is then used to provide the evaporation energy by condensation in the evaporator. An additional electrical heating system was included for initially starting the process.

Based on our experience in similar applications, the plant is designed to work continuously with evaporation and recirculation through a buffer tank. The tank has a decanting bottom which accumulates crystals which are then extracted through the bottom of the tank.

In this case, the plant has a vapour capacity of 350 kg/hr, but HRS Heat Exchangers can build similar systems between 200 and 25,000 kg/hr.

Operation

The evaporator is based on a Unicus Series dynamic heat exchanger to avoid fouling. The mixture of vapour and water containing salt crystals goes to a cyclonic separation chamber, where the vapour goes out through the top and the waste water goes down to the decanting hopper.

As explained above, there is a new liquid entry for recirculation in the evaporator, while the crystals go down to the bottom, where they are picked up by an extraction pump.

The vapour that comes out from the cyclonic separator is sent to a lobular vapour compressor that compress it to send it to the shell tube of the evaporator, where it condenses providing the necessary energy to continue the process.

Regulation and Control System

There is a PCL in the electro-pneumatic panel, with a LCD screen and an integrated keyboard for controlling the valves and plant engines. The regulation and working instructions are entered through the keyboard and the state of the plant and sensor readings are displayed on the screen. The control program allows for the continuous injection of the new product, along with evaporation and the unloading of concentrate. It also includes a cleaning cycle of the plant

Design Conditions

The system was designed within the following operating parameters and conditions:

- Product: wastewater

- Evaporation capacity: 350 kg/hr

- Evaporation temperature: 80°C

- Heating system: recompressed vapour

- Initial heating to get the regimen by electrical resistance

- Continuous working with recirculation

- Continuous unloading of crystal concentrate for crystal separation and liquid return.

- Estimated energy consumption (for 350 kg/hr):

- Electricity : 35 kW

- Compressed air: 5 lt/min. at 5 bar