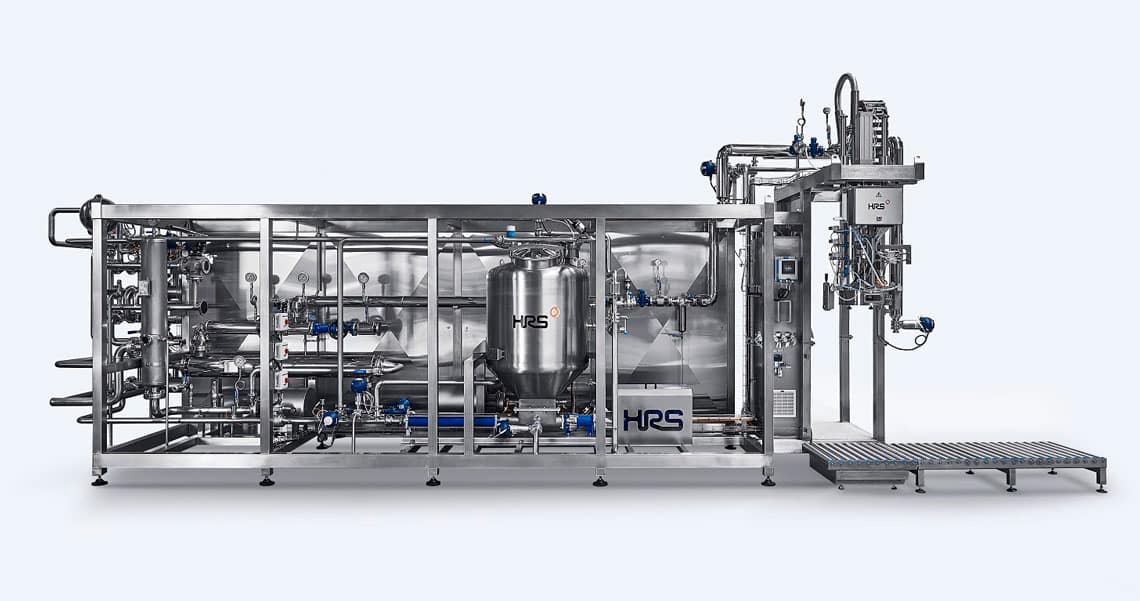

Multitube Heat Exchangers

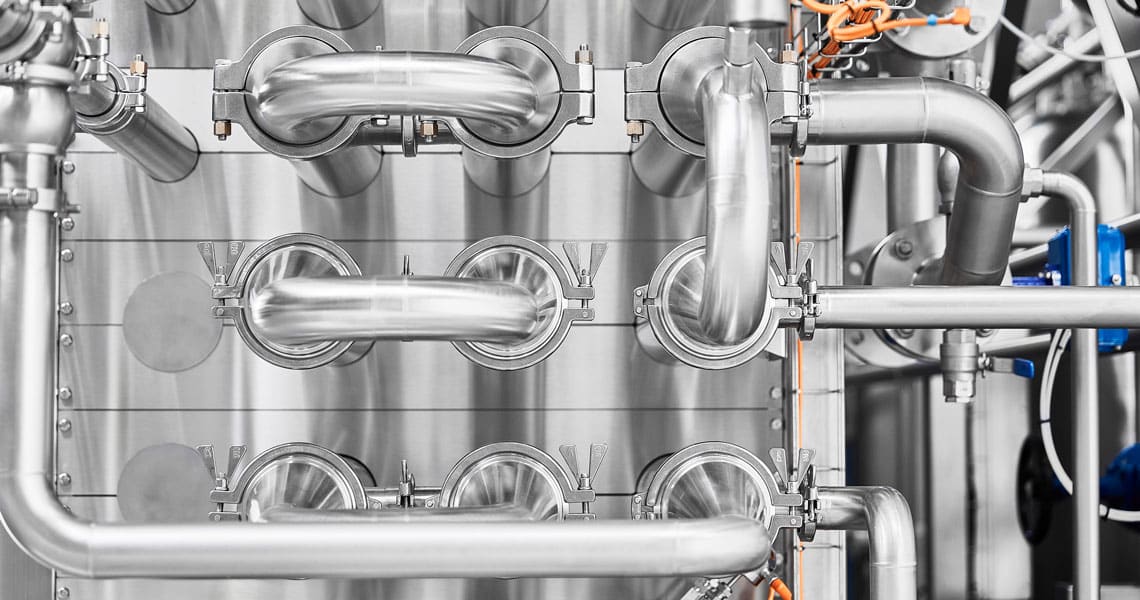

As the name suggests, a multitube heat exchanger uses more than one tube to carry the product. The product flows through the interior tubes and the service fluid flows through the surrounding shell. HRS produces a range of different multi tube heat exchangers for use in a wide range of different industries and applications.