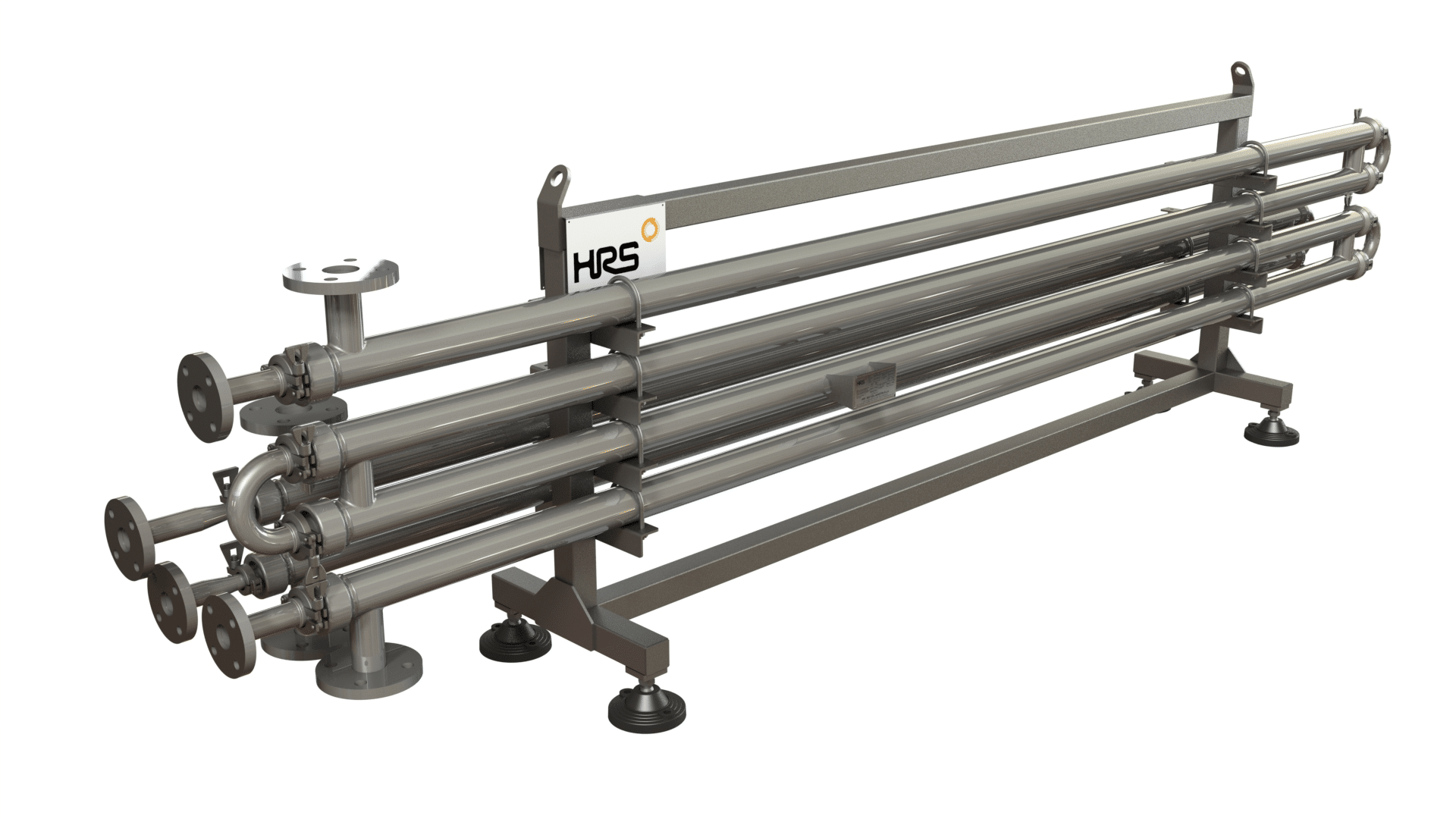

Industrial Double Tube Heat Exchangers with Removable Tube – HRS DTIR Series

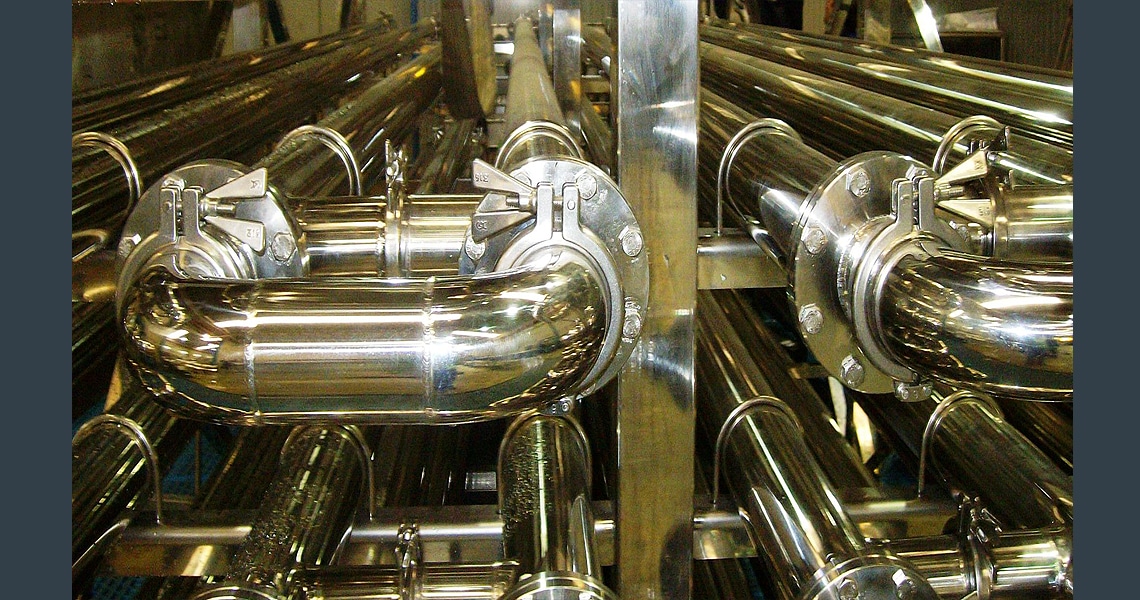

Based on the DTI Series, but with an adapted design for direct energy recovery (product vs product) for sludge with low viscosity. The inner tube is removable making it possible to inspect/clean both tube and shell side.

It also allows for easier and faster cleaning consequently reducing operational downtime required for these high fouling products.

The tube in tube concentric geometry makes it easy to work with fluids that contain particles, without having to worry about blockages impeding the flow of product. Special corrugated tubes are used to increase heat transfer and reduce fouling, making the DTIR Series more efficient than similar smooth tube heat exchanger designs.

For large duties, multiple units can be interconnected and mounted in a frame. Frame plating with thermal insulation can be provided for safety and to prevent heat loss and other options include frame mounting and stainless steel cladding.

Typical applications of the HRS DTIR Series include sludge heating/cooling and pasteurisation, digester heating and sludge-to-sludge heat recovery.

TECHNICAL DATA

Standard Materials of Construction:

- Service side: AISI 304 stainless steel

- Product side: AISI 316L stainless steel

Other material options available

Standard Connections:

- Service side: Flange

- Product side: Flange

All flange types available

Surface Finish:

- External: Matt

- Internal: Matt

Design code and compliance:

- PED 2014/68/EU, PD5500, ASME

- TR CU 032, DOSH Compliant