I Series (Ice Crusher & Melter)

The HRS I Series offers options to de-pack and crush (IC Series) and melt (IM Series) frozen juice (a process also sometimes known as re-melting) ready for storage and further processing.

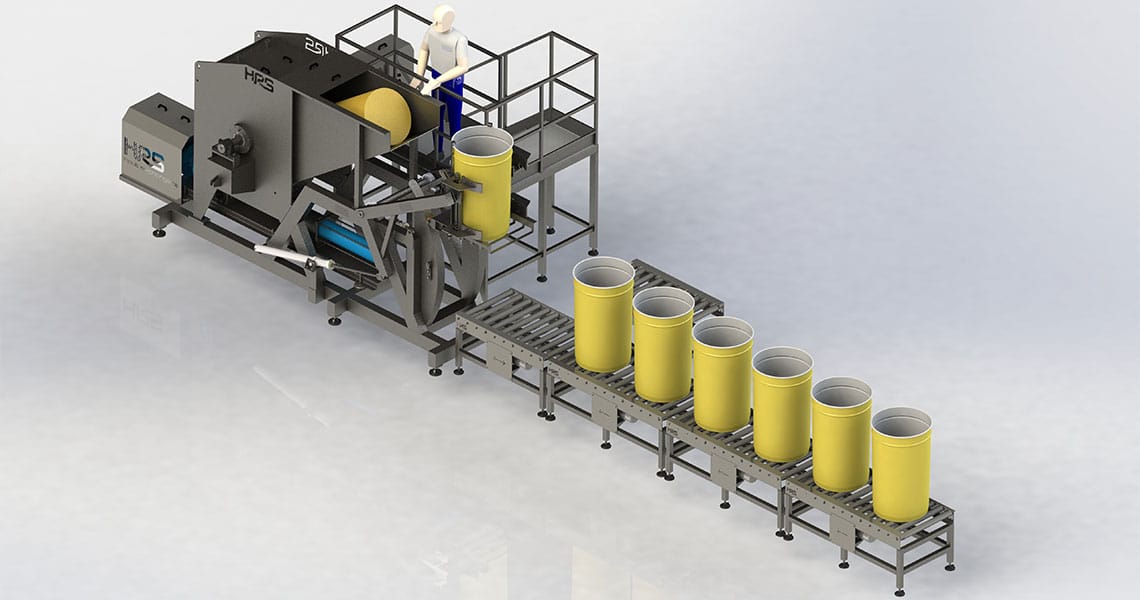

DRUM EMPTYING

The IC Series Crusher is specifically designed to empty 200 litre drums containing frozen fruit juice concentrates and fruit juices (up to 70° brix) with a maximum viscosity of 20,000 cP. Drums are loaded onto a roller conveyor system where the lids are removed and liners opened. The drum is then lifted and tipped automatically, allowing the majority of product to fall into the feed section, the remainder is emptied by feeding the bag into the squeezer.

CRUSHING

The crusher has a rotating drum which is fitted with a specially designed spiked roller. The roller then crushes the frozen product which drops into the hopper feeding the integrated positive displacement pump, the melted product is then pumped to the next stage of the process.

MELTING

The IM Series is designed for melting the crushed ice, this is done using either the HRS MI Series multitube or DTA Series double tube corrugated shell and tube heat exchangers, heating the product up to approx. 0°C, ensuring products can be pumped efficiently to the processing plant. Heating is achieved using hot water on the shell side of the heat exchanger, and the IM Series is fully cleanable in place.

INSULATION AND CLADDING

Great Energy Savings Potential

As with all HRS Corrugated Tubular Heat Exchangers designed for use in the hygienic industries, the IM Series Melter is fully clad in stainless steel for cleanability and has the option for insulation to prevent the inefficient loss of energy i.e. heating or cooling, whilst also providing protection for operators from hot or cold surfaces.

SYSTEM CAPACITY

Capable of handling up to 60 drums (12,000 litres) per hour.

The HRS I Series is suitable for the following products and applications:

- Juices

- Beverages

- Smoothies

- Purees

- Concentrates