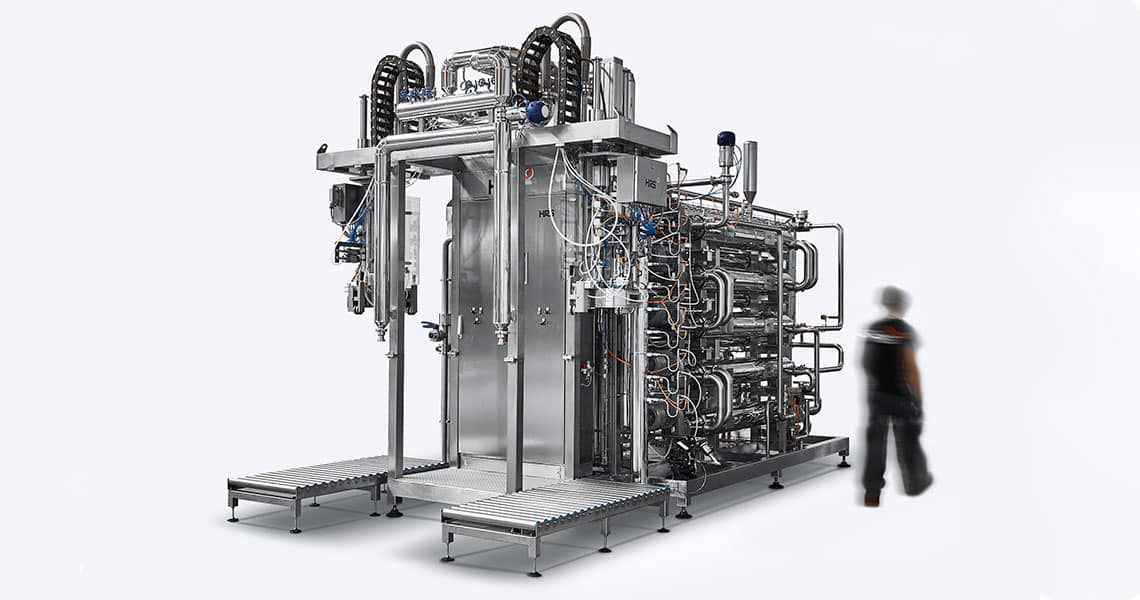

Aseptic Fillers – HRS AF Series

Aseptic filling ensures products remain safe, fresh and retain quality for up to twelve months, thus maintaining their taste, colour, texture and the essential nutritional values.

The HRS AF Series is a range of single and dual head aseptic fillers for use with ‘bag-in-box’ and ‘bag-in-drum’ type sterile packaging solutions.

HRS AF SERIES ASEPTIC FILLERS

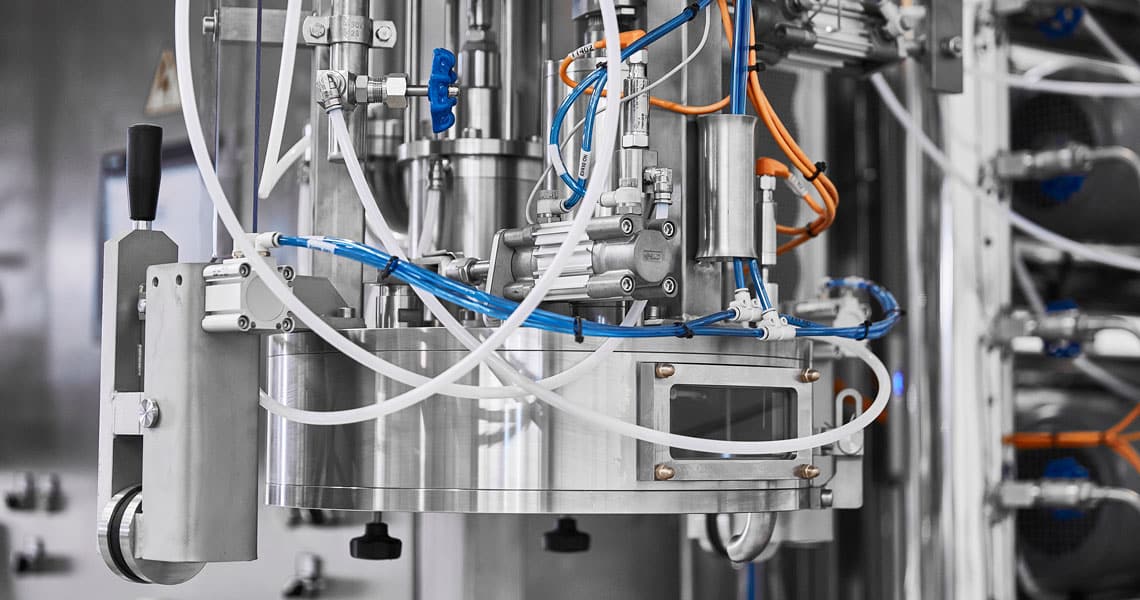

The AF Series has filling nozzles of 25 and 50 mm depending on the product, and works with pre-formed and pre-sterilised bags of between 5 and 1,000 litres.

The aseptic process ensures that both food and packaging materials are free of harmful bacteria when the product is packaged. In the process, thermal sterilisation of the product is carried out separately from that of the package. Sterile conditions during the packaging process are maintained using steam, so that chilled or ambient temperature product can be put into the container without any contamination before the pack is sealed.

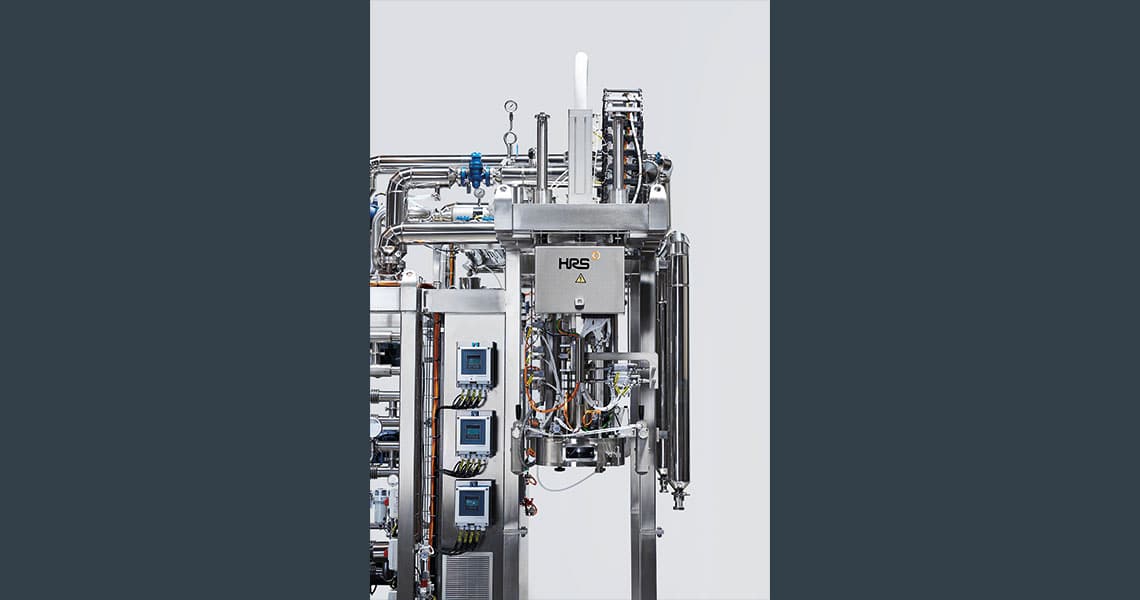

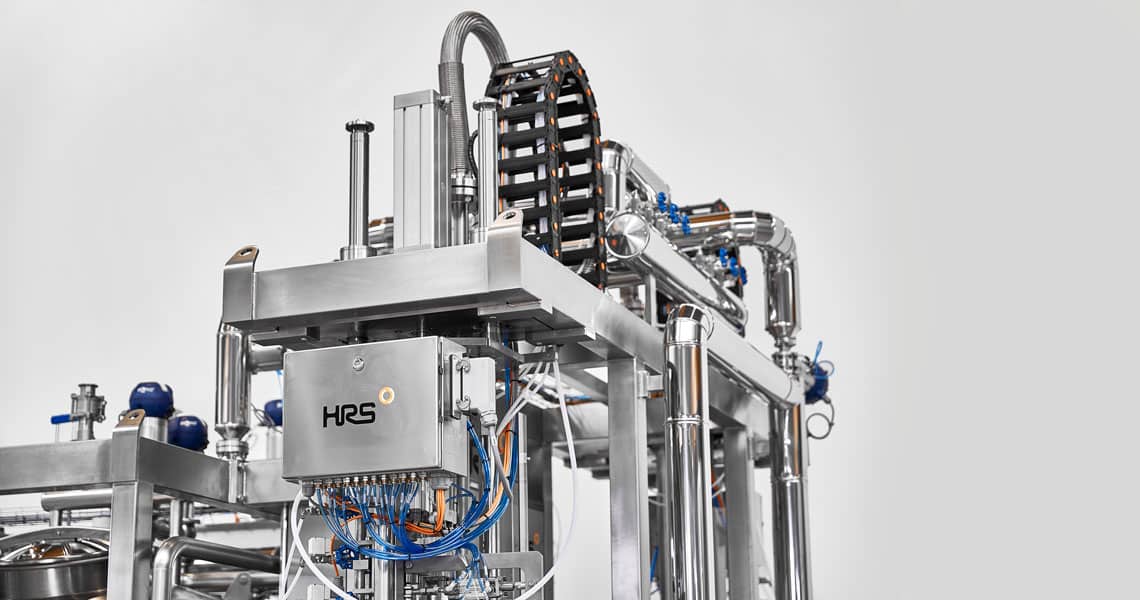

The aseptic filler has been designed for high and low acidity products and can fill fluids, concentrates and products with particulates. The automatic head design provides high filling speeds and performs motor driven vertical movement. Other features include automatic CIP cleaning, reliable weighing, control and monitoring of the finished packs.

The HRS AF Series of aseptic fillers is suitable for the following products and applications:

- Fruit pulp, purees and concentrates

- Fruits slices and dices

- Vegetable purees, dices and concentrates

- Vegetable soups and sauces

- Delicate products and concentrates

- Low and high acid products