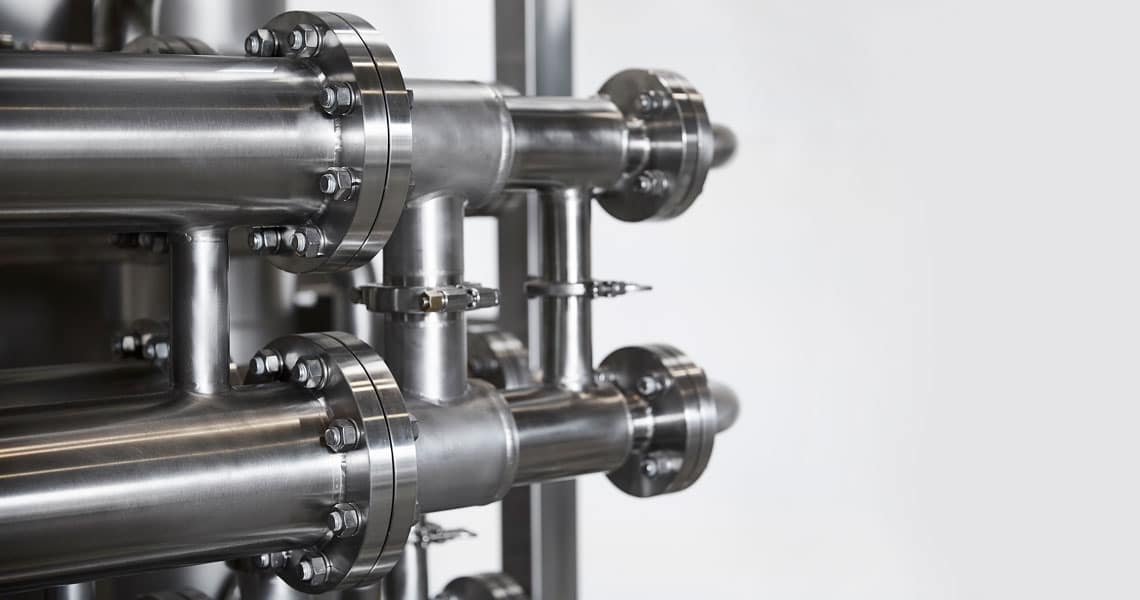

Scraped Surface Heat Exchangers

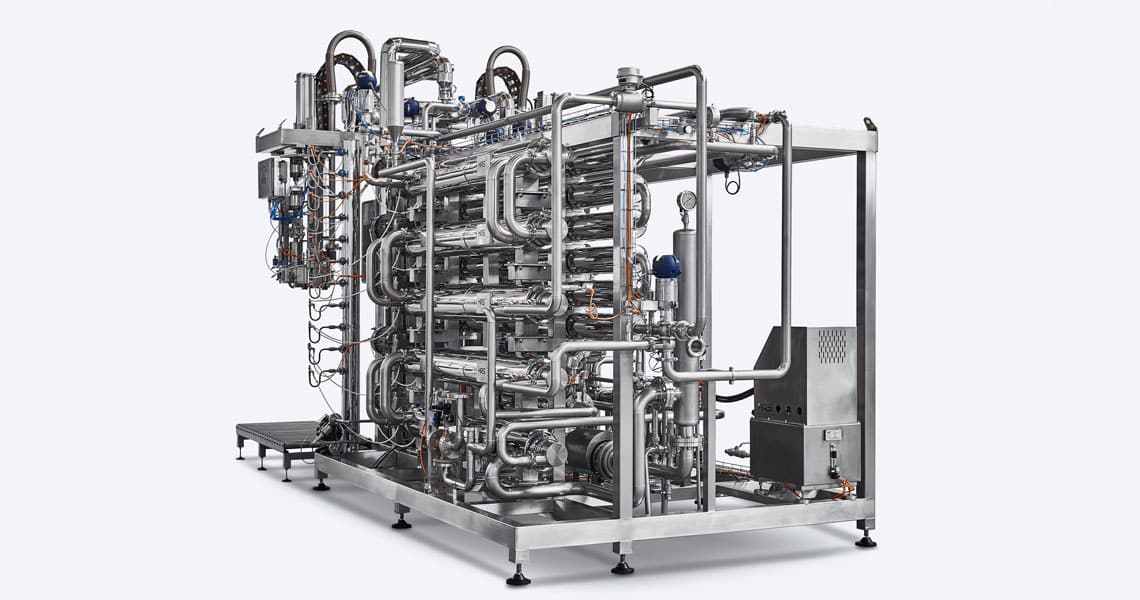

For difficult heat transfer applications, with high viscosities and where fouling can become a problem and surface area of shell & tube heat exchangers becomes uneconomical, the preferred option is a scraped surface heat exchanger. Scraped surface heat exchangers increase heat transfer and the heat transfer surface is constantly cleaned.

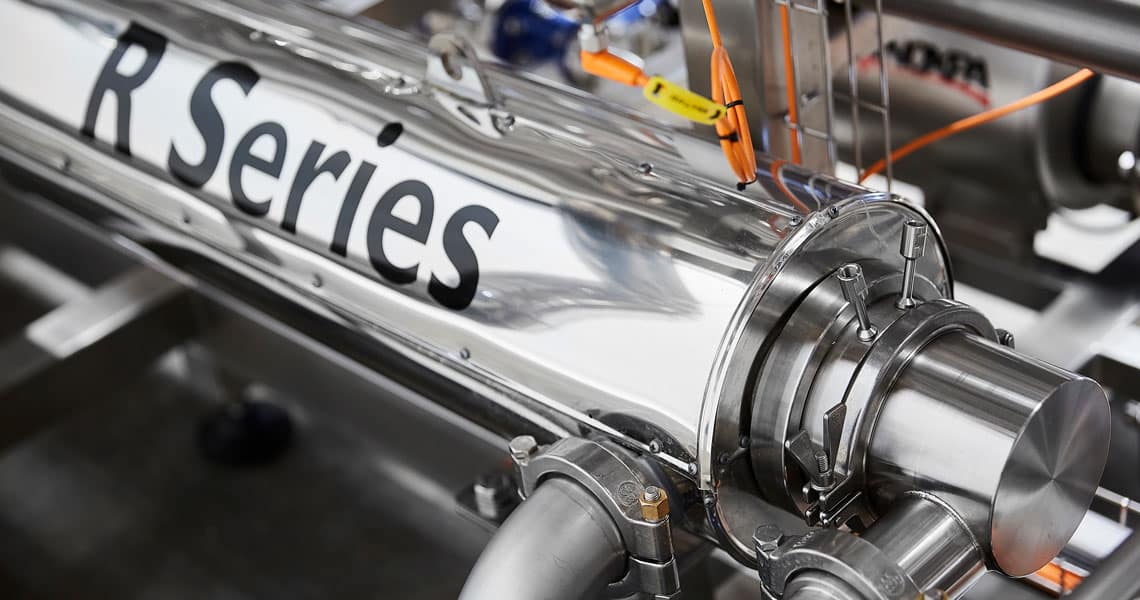

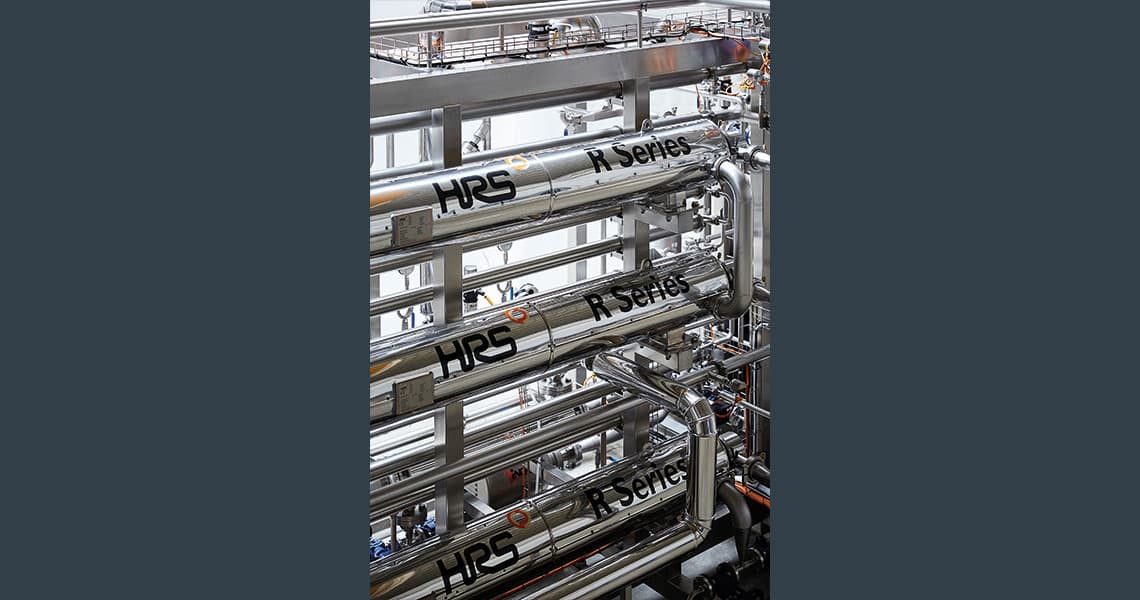

HRS offers two technologies for scraped surface heat transfer: the patented Unicus Series which reciprocates and R Series which rotates, each are designed for specific applications.

BENEFITS

HRS Heat Exchangers designs and manufactures scraped surface heat exchangers for applications where either one or both of the following problems require special solutions: fouling that causes heat transfer rates to drop and viscous fluids with extremely low heat transfer rates. The main benefits of scraped surface heat exchangers are:

-

Optimal performance and increased ‘up-time’

-

Ability to handle highly viscous fluids

-

Increased heat transfer

-

Keeping the heat transfer surface constantly clean

-

Larger heat transfer area per unit

-

Reduced footprint compared to standard shell & tube heat exchangers

-

Maintained product identity (Unicus)

PRODUCTS

FAQ

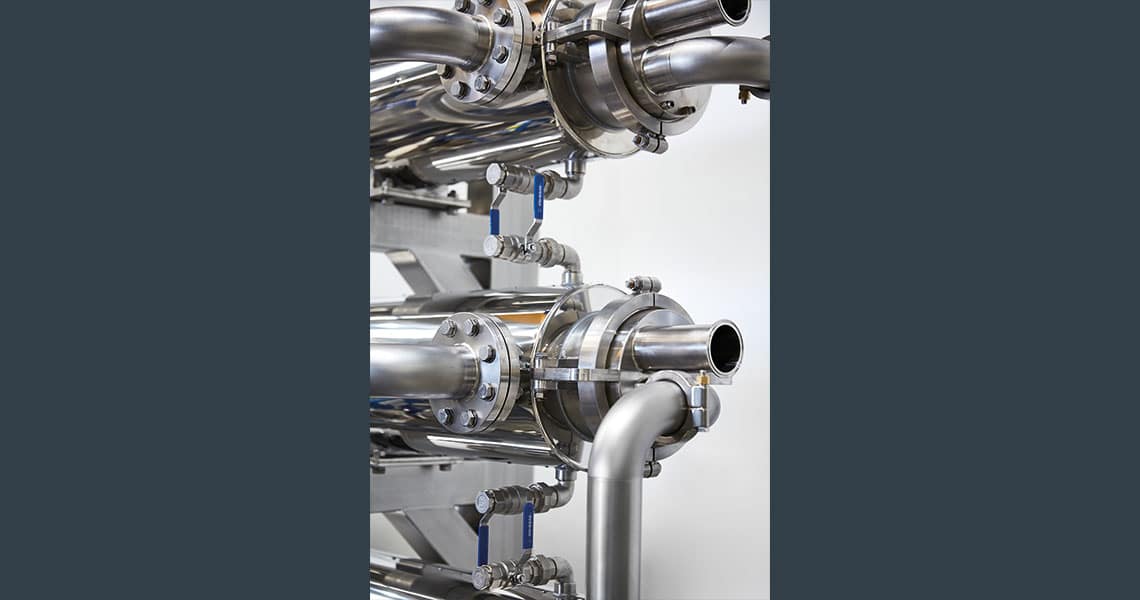

A Scraped Surface Heat Exchanger (SSHE) is based on a traditional shell and tube heat exchanger; they contain scraping rods fitted with scrapers inside each heat exchanger tube. Used in food & beverage, pharmaceutical, industrial, and environmental applications. They are ideally suited for highly viscous products. HRS has its own patented Unicus scraped surface heat exchangers that works on a reciprocating movement.

The benefits of scraped surface heat exchangers are:

- Optimal performance and increase ‘up-time’

- Able to handle highly viscous fluids

- Keeping heat transfer high

- Keeping the heat transfer surface constantly clean

- Larger heat transfer area per unit

- Reduced footprint

- Maintained product identity

Scraped Surface Heat Exchangers are used for difficult heat transfer applications, with high viscosities and/or where fouling becomes a problem, the preferred option is a scraped surface heat exchanger. Scraped surface heat exchangers keep heat transfer high and the heat transfer surface constantly clean.

The SSHE cleans the inner wall of the tubes and creates turbulence. This means longer running time and higher transfer rates. The alignment of the particles (laminar flow) is broken when the bars are moved counter currently. This adds an extra turbulence that helps increase the heat transfer coefficient.

In the food applications the Unicus is used when product identity or sheer sensitivity are important, and environmental applications where Scraped Surface Heat Exchanger’s are required with a large surface area per unit.