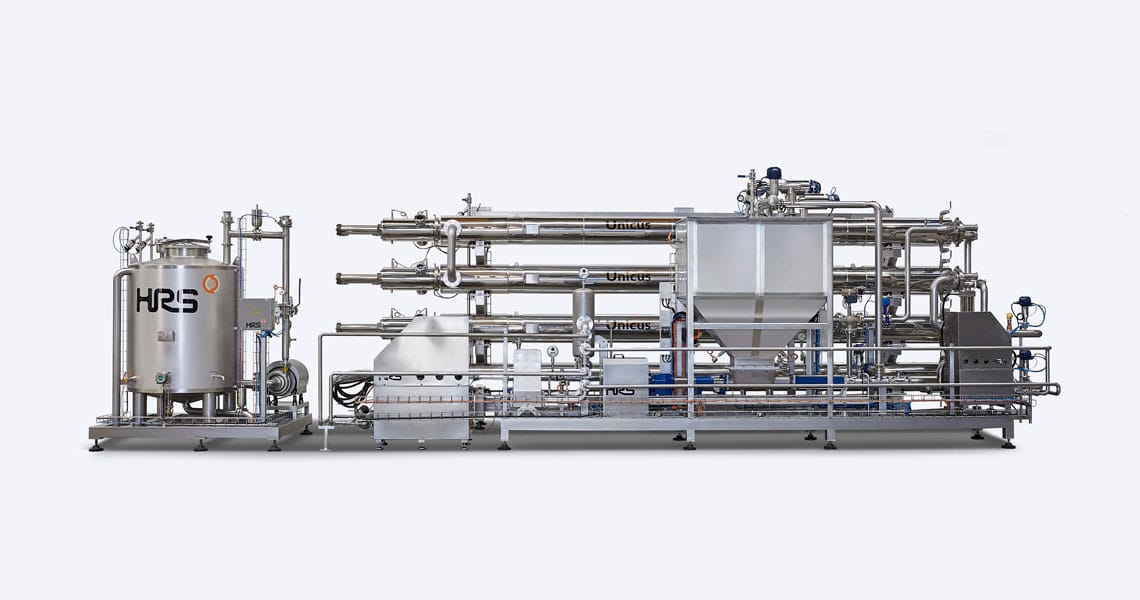

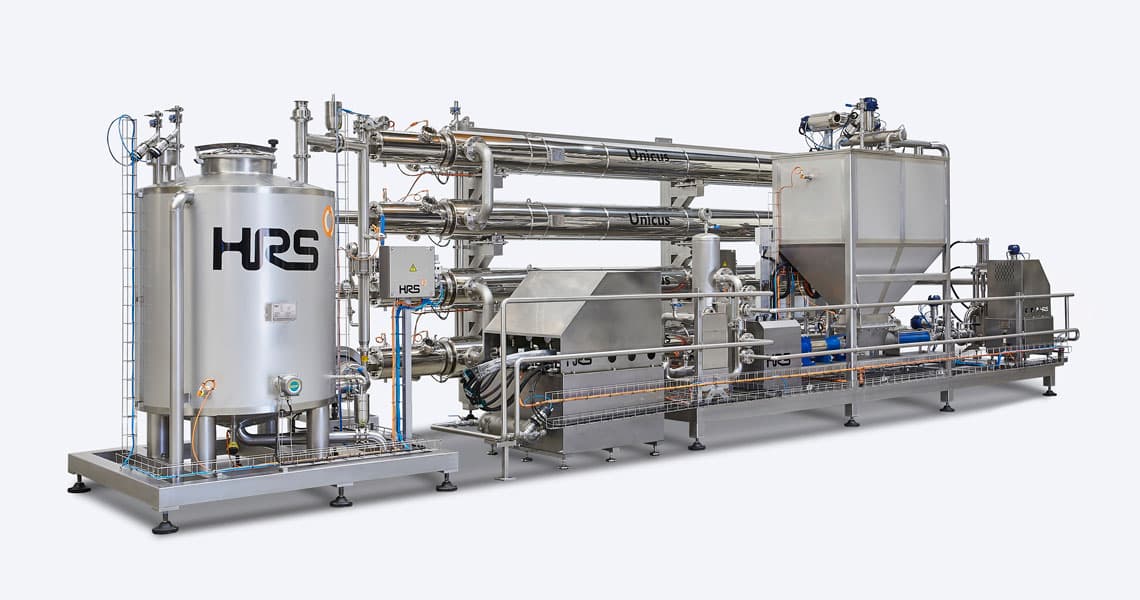

Reciprocating Scraped Surface Heat Exchangers – HRS Unicus Series

The patented HRS Unicus Series is a scraped surface heat exchanger specially designed and developed to offer a solution for those difficult heat transfer applications where very viscous fluids are used or fouling appears.

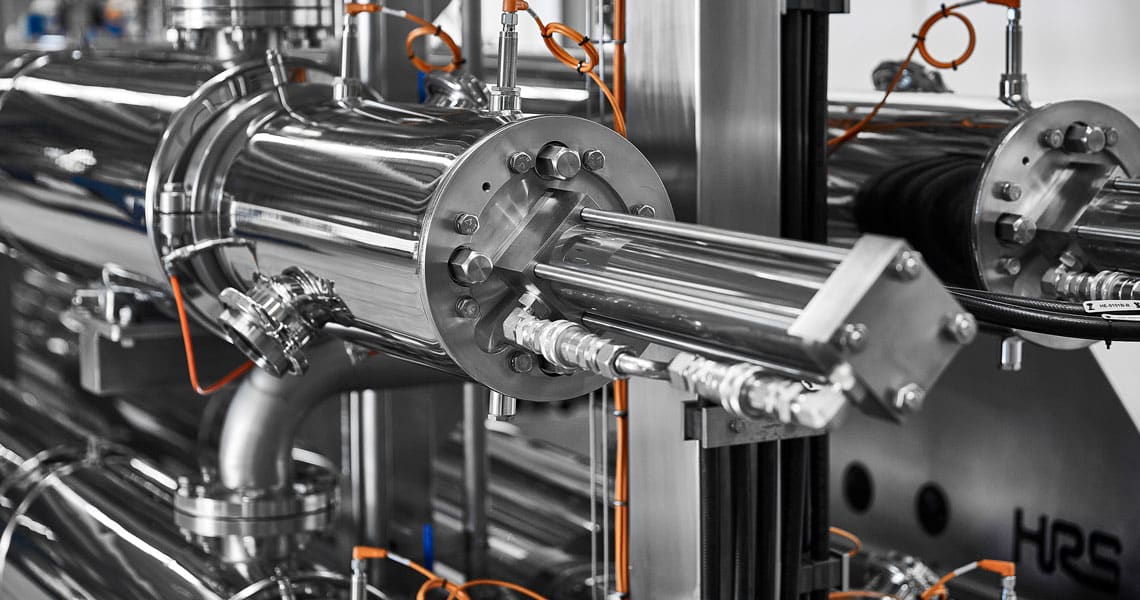

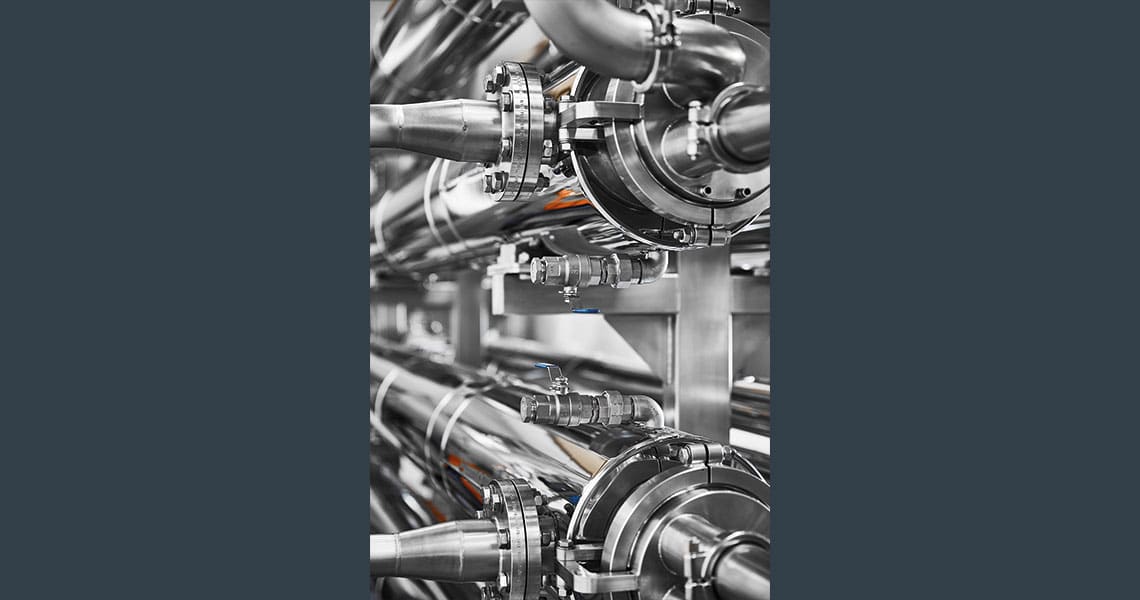

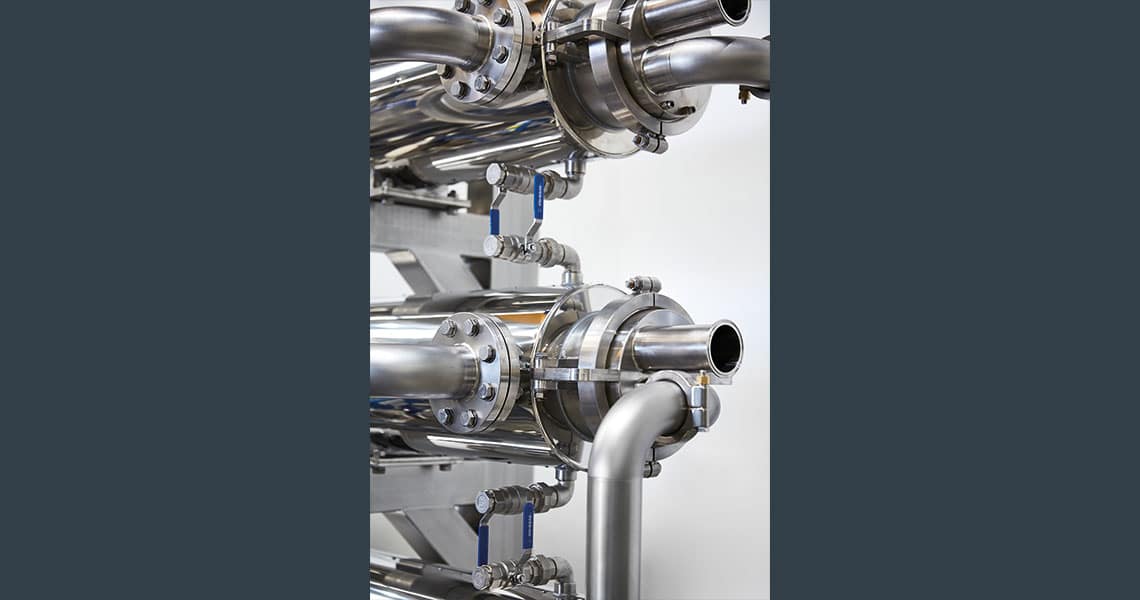

The design is based on a traditional shell and tube heat exchanger with scraping elements inside each tube. The reciprocating movement of the scrapers mix the fluid whilst cleaning the heat exchange surface. This keeps heat transfer high and reduces downtime. In addition, the scraping movements introduce turbulence in the fluid increasing levels of heat transfer.

This design makes the Unicus Series the ideal heat exchanger for applications where fouling or low heat transfer is a limiting factor. The Unicus Series can be applied in industrial and hygienic applications.

The gentle movement of the scrapers allows the system to be used with delicate products, such as whole fruit or vegetable pieces, without destroying the product integrity.

CONTINUED DEVELOPMENT

Continuous improvements have allowed HRS Heat Exchangers to apply the Unicus Series in a wide range of markets and applications. By increasing the stroke speed of the scraper bar we have been able to increase the heat transfer rates considerably. By adding new scraper types, we have adapted to the difficulties that new products may present. The increased range of models available has made it possible to offer economic solutions. From food industries to environmental, from heating and cooling to evaporation applications, the Unicus Series is a robust solution where other types of heat exchangers fail.

CHARACTERISTICS OF THE UNICUS

The Unicus Series heat exchanger consists of three main parts:

- The shell and tube part: Inside each interior tube a scraper bar is fitted.

- The separation chamber: This space separates the shell and tube heat exchanger from the drive cylinder that moves the scraper bars.

- Hydraulic drive cylinder: This part provides the energy that moves the scraper bars. The cylinder can be pneumatic (smaller models) or hydraulic (bigger models).

A key component of the Unicus Series is the seal that separates the inner tube volume from the separation chamber. The seal prevents leakage of the product to the exterior. Several types of seals have been developed depending on the application.

BETTER HEAT TRANSFER THROUGH SCRAPING

The scraping system consists of a stainless steel rod to which the scraping elements are fitted. Various types of scrapers have been developed for the different applications the Unicus Series can handle. Materials such as Teflon and Peek (polyaryletheretherketone) are used. 120° scrapers allow for working with larger particulates. The 360° scrapers are ideal for viscous fluid without particulates. As the product changes we adapt the geometry of the scraper. Scraping means fouling free heat transfer surfaces and increased ‘up time’ and performance.

Another advantage of the scraping action is the introduction of extra turbulence in the product. This results in a better transport of the product to and from the heat exchange surface which enhances heat transfer rates significantly.

UNICUS: A SCALABLE SOLUTION

As with any shell and tube heat exchanger scale up to bigger duties is as simple as increasing the shell diameter and adding more tubes in the shell. Unicus Series models are available from just one tube, up to 198 tubes. This gives the Unicus Series heat transfer areas between 0.7 and 180m².

A standard range of up to 10m² is available for hygienic applications. Larger models are designed for specific requirements.

Cross Section of the HRS Unicus Series

The HRS Unicus Series is suitable for heat transfer applications in a very wide range of industries and has multiple uses, including:

Products:

- Dairy: Cheese, yogurt, creams, desserts, whey concentrate, ice cream, condensed milk

- Fruits: Juice concentrate, fruit preparation, fruit puree, diced fruit

- Vegetables: Processed vegetables, tomato concentrate

- Convenience food: Eggs, mashed potatoes, ketchup, mayonnaise, baby food, dressings, spreads, fats, oils

- Protein: Viscera, meat slurry, mechanically deboned meat, meat stuffing, minced meat, pet food

- Confectionary: Chocolate, pie filling, creams, pastes, marmalade, syrups, gelatine, starch, butter, margarine

- Beverages: Coffee extract, juice concentrate, yeast-malt extracts

- Cosmetics: Lotion, cream, gel

- Environmental waste: Waste concentration: brine, manure, food plant effluent, chemical waste, solvent recovery

- Biofuels: Oil extraction for biodiesel, biomass pre-treatment, thermal hydrolysis, fermentation, digestate concentration

Processes:

- Heating

- Cooling

- Pasteurisation

- Crystallisation

- Evaporation (see below)

EVAPORATION

HRS Heat Exchangers designs a special version of the Unicus Series for evaporation applications. The principle is the same: a shell and tube heat exchanger with scraping rods in the interior tubes. During evaporation, fouling and reduced heat transfer can become a problem for traditional evaporators.

With the Unicus, the scraping action keeps the heat transfer surface clean and maintains high heat transfer, allowing the Unicus Series to concentrate to levels where traditional technologies cannot match. This makes the Unicus Series ideal solution for the concentration of environmental waste where volume reduction is vital. Unicus evaporators can be applied in a multi-effect setup or in combination with mechanical vapour recompression. Concentration under vacuum can also be applied with a Unicus evaporator, while the scraped surface operation allows continuous operation and reduces downtime.

TECHNICAL DATA

Standard Materials of Construction:

- Service side: AISI 304 stainless steel

- Product side: AISI 316L stainless steel

Other material options available

Standard Connections:

- Service side: Flange

- Product side: Clamp/Flange

All flange & clamp types available

Surface Finish:

- External: Polished or Matt

- Internal: <0.8μ

Design code and compliance:

- PD 5500, PED 2014/68/EU, 2006/42/CE, ASME

- FDA, 3A, TR CU 032, DOSH Compliant