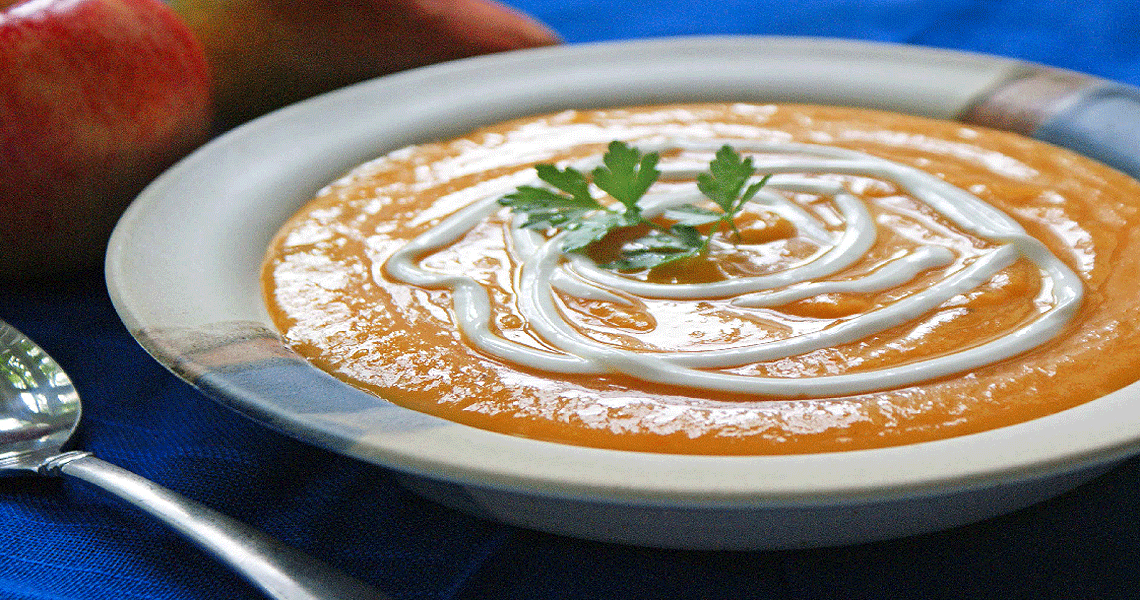

Soups

Soup has been a popular product for many years, but improvements to flavour and texture have, reduced salt and fresh gourmet soups are changing the way that soup is prepared and packaged.

HRS Heat Exchangers has the most modern technology available for the commercial production of soups.

HRS has considerable experience in the design, supply and installation of heat transfer, pasteurisation and fillers for soup products.

Turnkey installations already supplied have various sections including ingredient preparation (chopping, crushing etc. as appropriate) cooking/browning section, emulsifying, homogenisation, deaeration and sterilisation.

The use of the Unicus Scraped Surface Heat Exchangers in the sections of cooking/browning and sterilisation avoids the tendency for soups to precipitate out certain ingredients. As the heat exchange surfaces of the Unicus always stay clean, the system can work continuously and therefore operate at maximum efficiency.

Pasteurisation systems supplied by HRS allows soup manufacturer to adjust the heating-holding-cooling cycle for each product to best suit the product requirements. The HRS pasteurisers allow the user to work with the HTST (High-Temperature Short-Time) method. This gives a very efficient process which allows the sterilisation process to be optimised to ensure that the desired results are obtained while at the same time the undesirable effects (loss of organic and/or nutritive properties) are minimised.

HRS usually includes an HRS BP Series piston pump in soups installations, since it performs a gentle fluid handling, with a low shear rate, very important in the case of soups with particles or toppings, the pump does not damage them.

HRS offers the following technologies for soup processing:

- Scraped Surface Heat Exchangers: HRS Unicus Series & HRS R Series

- Hygienic Double Tube Heat Exchangers: HRS DTA Series

- Hygienic Multi Tube Heat Exchangers: HRS MI Series

- Food Processing Systems: HRS Aseptic Block Series, HRS Thermblock AS Series / DTA Series / M Series

- Piston Pumps: HRS BP Series

- Cleaning-in-place: HRS CIP Systems