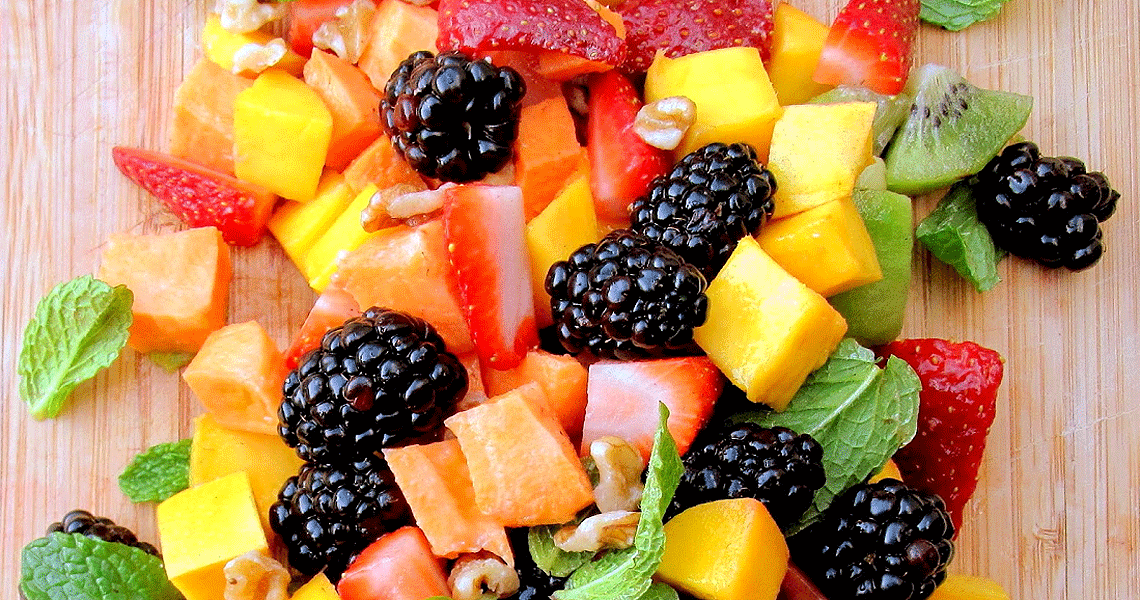

Fruit Dices, Rounds and Slices

Chopped fruit and vegetables which are aseptically packed and ready to use form have become increasingly popular in recent years.

In 1995 HRS supplied the first diced fruit aseptic plant in Spain to one of the main manufacturers in the market. Following this, we have supplied numerous plants for a wide range of fruit including peaches, apricots, strawberries, apples, pears, and more.

HRS has a proven track record in providing turn-key plants for fruit processing and dicing, which feature the latest technology. Mastering the process has allowed us to develop other applications and add further value to processed fruit products, such as diced fruit bases for further processing and confectionery products.

We provide a range of equipment, including heat exchangers, piston pumps, evaporator technologies and our aseptic filler. Combining them makes it possible to provide a complete turn-key plant which processes the fruit while minimising any undesirable thermal effects.

PREPARATION AND BLANCHING

The fresh fruit is washed and selected before going to the cutting and mashing. Then, the fruit goes to the heat exchanger to be pre-heated, which produces an enzymatic deactivation (60/80ºC), in the so-called blanching process. The juice from the fruit will act as a carrier liquid (no liquid is added).

PASTEURISATION

The fruit slices or pieces are sent to the specially designed air removal tank. Here, a combination of vacuum and temperature removes the air that could cause fruit oxidation. An aroma condenser recovers the aromas and a piston pump, also specially designed, slowly pumps the product to the next stage.

THERMAL TREATMENT

The treatment zone consists of four modules:

- Heating with hot water (90/105°C),

- Holding

- Cooling (25/35°C) with tower water

- Sterilisation

The cooling cycle recovers heat and returns it for use in other heating or sterilising operations. Using appropriate corrugated tube heat exchangers ensures the correct sterilisation of the fruit pieces.

FILLING

Finally, the system includes an aseptic filler with an optional double header, which is specially designed for fruit particulates.

The advantages of the HRS Heat Exchangers fruit processing systems include:

- The Piston Pump has been specifically designed to so that it does not damage the fruit.

- There is no liquid added to the fruit. The product that you obtain in the bag is what is known as “solid pack”.

- The crucial air removal process is carefully controlled.

- The thermal treatment is very rapid, homogeneous and effective thanks to the corrugated tube heat exchangers.

- The products remain very natural and maintain their organic and nutritional properties.