The Benefits of Shell & Tube Over Plate Heat Exchangers

For simple non-viscous fluids, the choice of heat exchanger normally comes down to a choice between plate heat exchangers (PHEs) and shell and tube designs. There are a number of considerations which are not always taken into account when evaluating the advantages of shell and tube and plate heat exchangers.

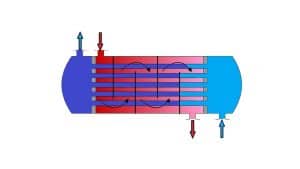

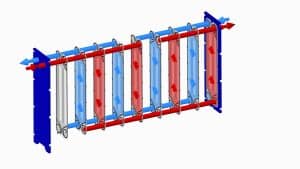

As the name suggests, a plate heat exchanger consists of series of pressed metal plates separated by gaskets. The service fluid (which provides the heating or cooling effect) and the product (the material to be heated or cooled) flow through the gaps between alternate plates. In contrast a shell and tube design feature a tube (or series of tubes) running through a shell. The product flows through the tube and the service fluid through the gap between the tube and the shell.

Advantages of plate heat exchangers include their simplicity and high heat exchange performance (when used with simple fluids). However, the capital costs of the two technologies are not always clear cut. Neither are the differences in pressure drop created by the two designs, but tubular heat exchangers are generally capable of operating at higher temperatures.

One claimed benefit for PHEs is that they are easy to dismantle and clean but removing lots of separate plates and their corresponding gaskets is not particularly convenient. It also ignores the fact that well designed tubular heat exchangers are less likely to need regular dismantling to allow for deep cleaning, and that this can be facilitated by the use of removable tubes.

Total cost of ownership (a combination of the capital cost and operational costs over the working life of the unit) is a major factor when considering which type of heat exchanger to invest in, and one of the biggest maintenance costs involved in running plant heat exchangers is gasket replacement.

The gaskets between each plate are an inherent design feature of PHEs but they are prone to failure, particularly when operating at high temperatures, particularly where operation involves a large number of repeated heating and cooling cycles. Even when they do not fail, regular gasket replacement is often part of the standard service requirement. Meaning the price of gaskets needs to be considered in the overall cost of ownership, along with associated down time. Because the majority of shell and tube designs are of welded construction, there are no internal gaskets to fail or replace. Where removable tubes are used, O-ring gaskets are the norm, making them much easier and cheaper to replace than the bespoke gasket designs required for plate heat exchangers.

Once the cost of gasket replacement is factored in over the life of a plate heat exchanger, then the total cost of ownership assessment swings back towards shell and tuber heat exchangers. With much simpler routine maintenance and cleaning, and no need for the regular replacement of expensive, bespoke gaskets, more and more users are appreciating the benefits of shell and tube heat exchangers.