Pasteurisation of juices, purees, gazpacho, soups, broths and soya based drinks

The HRS pasteuriser allows the user to adjust the heating-holding-cooling cycle for each product to best suit its requirements with the HTST (High Temperature Short Time) method, where the product is subjected to a high temperature for a short time, thus giving an efficient process allowing sterilisation to be optimised ensuring that the desired results are obtained, whilst minimising the loss of organic and/or nutritional properties.

DESIGN CONDITIONS

Example of typical design conditions:

| Products | Natural citrus juices Orange Juice with pulp Peach Puree Apple Juice Grape Juice Pineapple Juice Red Fruit Juices Tropical Fruit Juices Multifruit Juices Gazpacho Fruit Juice with 6% milk Creams Soups and stocks Soya based drinks |

| Inlet product temperature | 5/20 °C |

| Outlet product temperature | 0/2, 15/25 or 85/90 °C |

| Pasteurisation temperature | Adjustable between 85-130°C |

| Holding time | 0-10-20-30 seconds (modular) |

| Direct energy recovery | 70-80% depending on the product |

| Deaeration | Product Dependant |

| Equipment sterilisation temperature | Above 140 °C |

DESCRIPTION AND OPERATIONS

Product reception and pumping

The plant starts with an initial balance tank designed specifically to suit the type of product processed in the plant.

At the start of the line we have the following inputs:

- Water inlet for rinsing and blockage clearance

- Product inlet

In the return line we have the following items:

- Product return to the initial balance tank

- Inlet to the balance tank for CIP cleaning

- Outlet to drain/recovery

The product for processing is pumped towards the deaerator where all necessary pressure related safety devices are fitted.

Following this, the product is pumped through the direct regeneration heat exchanger (product-to-product) using the HRS MR in which the product is preheated using the heat from the outgoing hot pasteurised product. This increases the overall energy efficiency of the pasteuriser.

DEAERATION SYSTEM

The deaerator is fitted in the pasteuriser system if the product requires it. Aroma recovery is included where applicable

THERMAL TREATMENT

The optimal thermal treatment for processing the product is described below. In this example, we use the HRS MI and MR series heat exchangers which are suitable for this application. Where applicable and required, a temperature sensor and a visual thermometer is fitted to control the process at various stages.

- Preheating 1 (direct regeneration)

The product is preheated in the MR type corrugated multitube heat exchangers. This is a direct recovery of energy using the product itself to provide the heat needed for the preheating phase. After preheating, the product passes through the deaerator.

- Preheating 2

After deaeration, the product is subjected to a second regenerative heat treatment similar to the first. By using MR type corrugated multitube heat exchangers, we can achieve recuperation values between 70 and 80% heat recovery from the product.

- Heating

Following the second stage of recovery, the product is heated further to the pasteurising temperature using the MI type corrugated multitube heat exchangers. To avoid large differences in temperature between the product being heated and the service fluid, we use superheated water as a heating medium. This service fluid is heated to the controlled temperature using steam as a heating medium in a K series corrugated multitube heat exchanger. At the outlet from each of the preheating and final heating sections, a temperature sensor is fitted to control the temperature at which the product enters the holding section. In order to give visual control a sanitary visual thermometer is also fitted at the product outlet.

- Holding 2

Once the product has reached the pasteurisation temperature, it is necessary to hold it at that temperature for a predetermined time (the holding time). The length of the fitted holding tubes is calculated to provide sufficient residence time (product dependant between 0 and 30 seconds) and to minimise the pressure loss. At the end of the holding section, two temperature sensors are fitted (duty/standby to give additional security to the process) with temperature recording. A visual thermometer for manual control of the system is also included.

- Cooling

When the pasteurisation is completed, the product is cooled and sent to the aseptic filler. The cooling is carried out using multitube heat exchangers in three different sections (in the following order):

Preheating 2 (Regeneration)

MR type corrugated multitube heat exchangers using direct product-to-product recovery.

Preheating 1 (Regeneration)

As explained earlier, the hot product is cooled by the incoming cold product and the pasteurised product passes through the hygienic tubes.

Cooling

MI type corrugated multitube heat exchangers are used with chilled water and/or glycol as the cooling medium.After the cooling module, a temperature sensor and a visual thermometer are fitted to enable the process to be controlled. After the cooling section and before the aseptic valve leading to the filler/tank, a refractometer is fitted to enable the °Brix to be measured at the outlet.

- Hot divert to the sterilisation cooler

After the holding section, a three way divert valve is fitted for security, allowing product which has failed to reach the correct pasteurisation temperature to be diverted back to the start of the processing line where it can either be reprocessed or recovered into storage drums.In the return line to the balance tank, an MI type corrugated multitube heat exchanger is used to cool the diverted pasteurised product to ensure that the return to the initial deaerator does not result in unwanted evaporation or flash steam.

- Sterilising the equipment

Sterilisation at a temperature in excess of 140°C for at least 20 minutes.

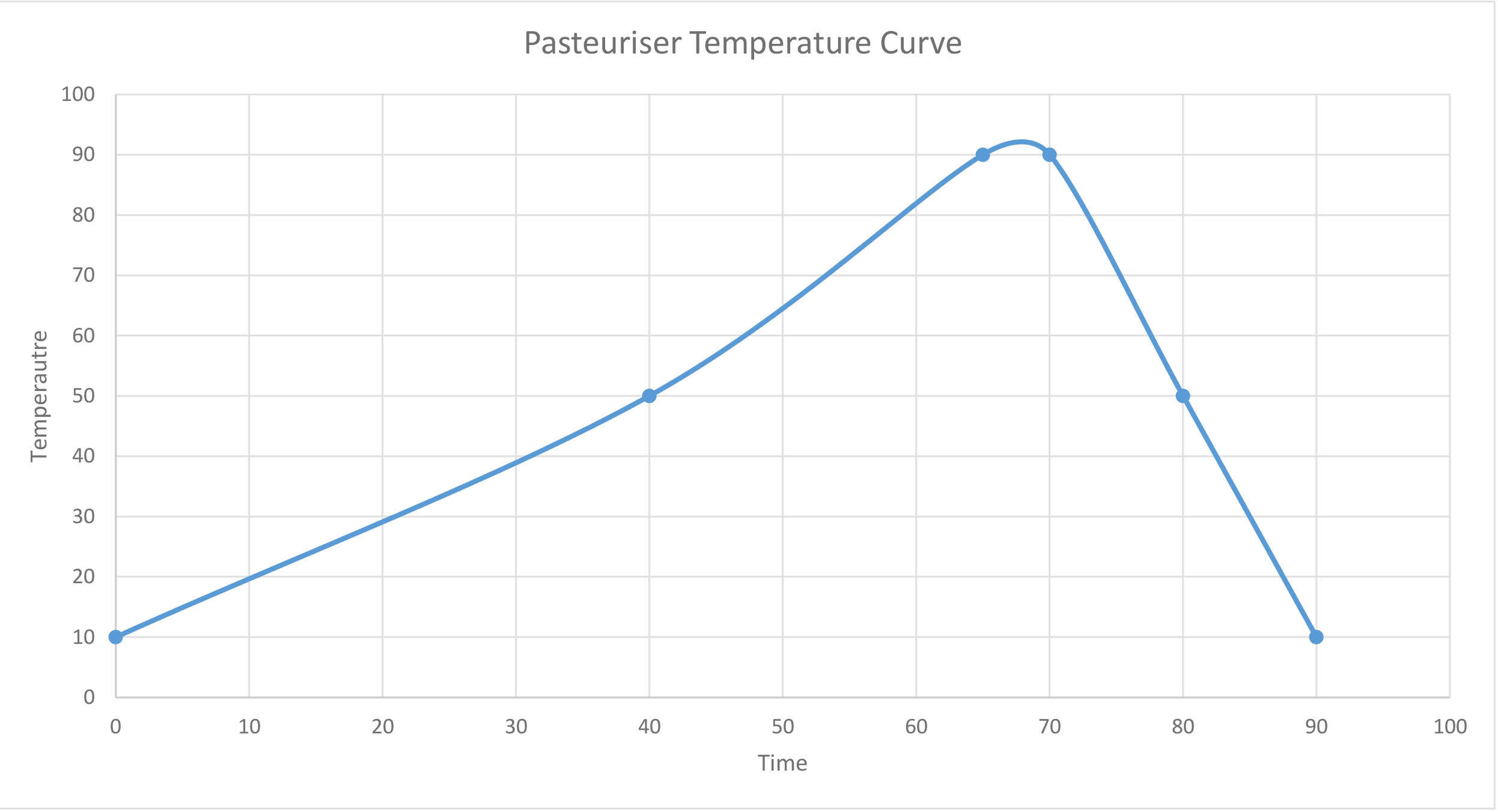

- Typical Temperature Curve

HRS ASEPTIC TANK

The system has an aseptic expansion tank in the pasteurisation line and includes the following items:

- Stainless steel tank with cooling jacket

- Connection of the product line between the pasteuriser and the expansion tank

- Connection of the tank with the filler

- Inlet line for nitrogen or sanitary air, including the valves and filtration systems

- Steam inlet connection for tank sterilisation

- Steam inlet for steam barriers in processing line valves and pipework flanges

- Steam inlet for sterilisation of the connection lines to the filler

- Complete product lines to allow:

-

- Tank filling

- Tank filling and packing at different rates

- Direct packing without using the aseptic tank

- Sterilisation of the system

- CIP cleaning of the system

PRINCIPAL ELEMENTS

The system has an aseptic expansion tank in the pasteurisation line and includes the following

- Product pump

- CIP circulating pump

- Deaerator pump

- Heat exchangers

- Pasteuriser: HRS MI/MR series corrugated tube heat exchanger

- Aroma recovery: HRS MI series corrugated tube heat exchanger

- Water heater: HRS K series corrugated tube heat exchanger

- Deaerator

- Aroma recovery

- Electromagnetic flowmeter

- Homogeniser

- Balance tank

- Aseptic tank

- Control system

- CIP system