Heat exchangers meet the challenges of pet food production

The UK is a nation of animal lovers, with 40% of households owning a pet. A quarter of UK households have a dog, and there are some 9 million canine companions around the country. Our feline friends are only just behind them with 7.5 million British cats¹.

As a result, the UK boasts some of the highest feed safety and animal welfare standards in the world, and consumers are increasingly knowledgeable about products and quality. However, producing high quality pet food which appeals to pets and their owners and which meets the necessary standards presents manufacturers with some specific challenges. The total pet food market in the UK is worth £2.9 billion and, unsurprisingly, is dominated by dog (£1.4bn) and cat (£1.2bn) products.

The heat is on

Thermal processing is a key part of pet food manufacturing, with processes including heating (pre-conditioning), cooking, drying, pasteurising and cooling. However, the thick, viscous nature of many of the meat-based products presents challenges for handling, heating and cooling. Different types of food obviously require different types of processing; not only in terms of wet or dry, but also solid pâtés compared to meat chunks in jelly or gravy.

Delicate handling

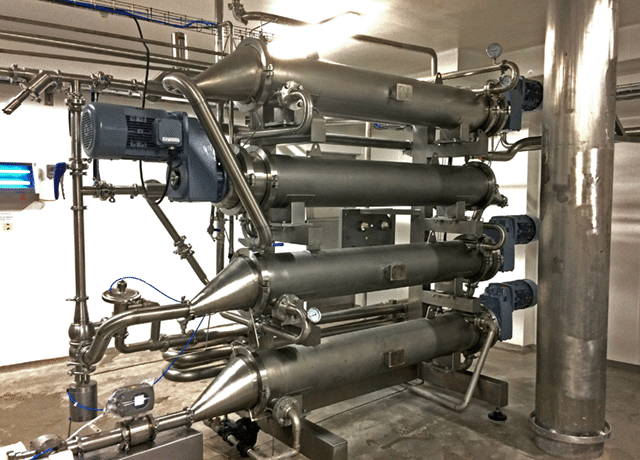

The HRS R Series and Unicus scraped surface heat exchangers (SSHEs) are ideally suited for pet food processing, including heating ingredients such as meat slurry, jelly and gravy before further processing, as well as heating or cooling soft meat or fish ingredients. In addition, HRS BP Series high-pressure positive displacement piston pumps are perfect for delicate materials containing particles, such as pet food chunks.

Pet food ingredients such as meat products and slurries need delicate handling to maintain texture and quality. However, they are also comprised of very thick and viscous material which can be difficult to move, making them unsuitable for rotary pumps. Their viscous nature means they have a high fouling potential during heating or cooling which can reduce the thermal performance of heat exchangers.

Overcoming viscosity challenges

The R Series uses a patented rotary scraper bar which can reaching speeds up to 300 rpm, providing high levels of shear and mixing at the heat transfer surface which dramatically increases heat transfer rates. This makes it particularly suitable for challenging heat transfer applications, such as those where the product requires high pressures or has high viscosity.

The scraper bar features both a helical mixing spiral (which helps reduces the pressure drop in the tube) and a series of scraper blades. Together these provide a continuous scraping action which mixes highly viscous products and reduces fouling. The unique design enables high viscosity products to be pumped with reduced back pressure and lower energy use, in a compact unit which features a much smaller footprint than traditional heat exchangers for similar applications.

Maintaining product integrity

In contrast, the patented Unicus Series is designed to provide unrivalled heat transfer of a wide range of difficult meat products which have high fouling potential, but which also need delicate handling to preserve fragile product integrity.

Another benefit is the fact that the separate hydraulic action enables the speed of the scrapers to be controlled and optimised for the product being processed. This means that materials which may be susceptible to shear stress or pressure damage, such as chunks with jelly and gravy, can be handled gently while still providing high levels of product identity.

¹ Pet Food Manufacturers’ Association: https://www.pfma.org.uk/market-data-2019