Annular Space Heat Exchangers Benefit Conventional Scraped Surface Applications

Traditionally scraped surface heat exchanger (SSHE) technology has been the preferred method selected by processing lines for heating and cooling viscous products.

Triple tube corrugated tubular heat exchangers, commonly known as annular space heat exchangers (AS Series) can be utilised in many applications as pre-heaters or pre-coolers prior to the SSHE.

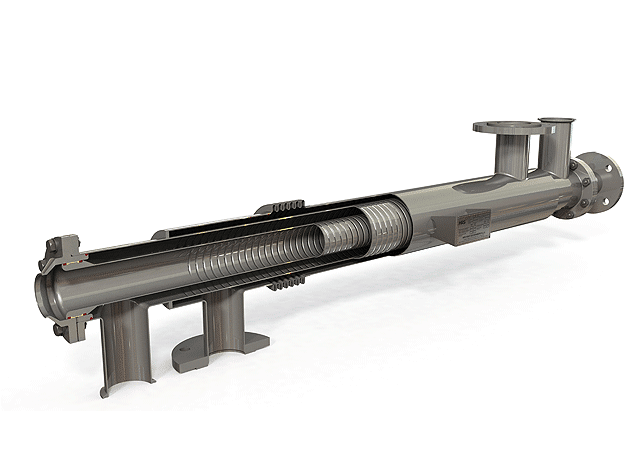

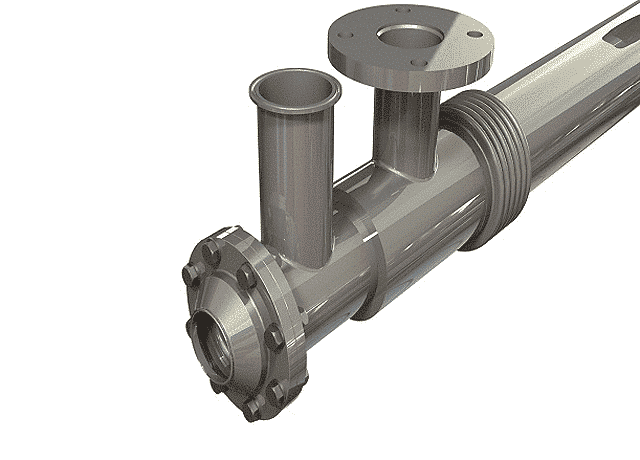

The HRS AS Series is a fully stainless steel, triple tube heat exchanger for applications with viscous products. The product flows through the annular space and the service fluid flows through the inner and outer tubes to ensure even heating and cooling. The removable inner tube allows for easy inspection of the annular space. Using HRS’ corrugated tube technology, both heat transfer and efficiency are increased over standard smooth tube heat exchangers. In addition, potential fouling is service fluid flows through the inner and outer tubes to ensure even heating and cooling. The removable inner tube allows for easy inspection of the annular space. Using HRS’ corrugated tube technology, both heat transfer and efficiency are increased over standard smooth tube heat exchangers. In addition, potential fouling is minimised.

The AS Series is designed specifically to maintain the correct velocity and back pressure required by the processing line, whilst delivering the most efficient heat exchanger for your product, prior to the provision of an SSHE.

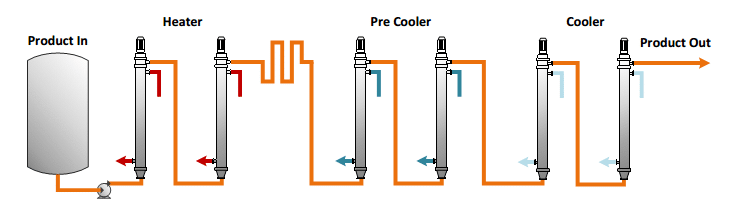

SSHEs are commonly found throughout the complete heating and cooling process of a conventional installation; which generally creates a vastly expensive processing line. (Figure 1).

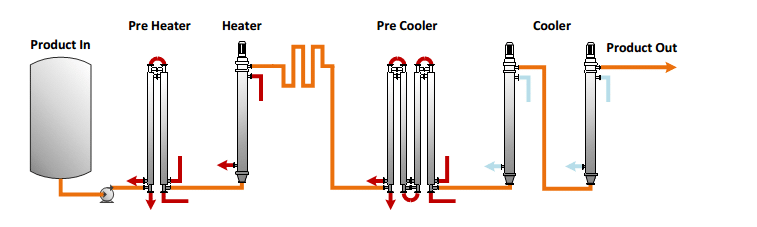

End users are only too aware of the heavy workload necessary to keep SSHEs running; aside from the continual capital investment and maintenance work involved. By replacing a proportion of these heat exchangers for the AS Series (until the line negates a SSHE), existing clients have made significant savings across the board, resulting in lowered maintenance costs, reduced down time and a cleaner operational processing plant. (Figure 2).

Alongside our annular space heat exchangers, HRS also design and manufacture rotary (R Series) and reciprocating (Unicus Series) scraped surface heat exchangers. In our experience, combining both technologies throughout the processing line provides end users with unparalleled benefits both in the short and long term.

HRS manufactures both standard and high pressure annular space heat exchangers. The design conditions for the standard series are 10 bar for both the product and service side at 150°C and 27 bar at 150°C for the high pressure series.