Clean Sweep of Orders for HRS India

Over the past 12 months, HRS India has paved the way to becoming the preferred choice amongst fruit pulp producers and exporters. Having shown great promise within the hygienic sector; HRS India has secured a string of impressive orders for their novel HRS Monobloc Steriliser; whilst creating further sales expansion across several new states to include Maharashtra and Kerula.

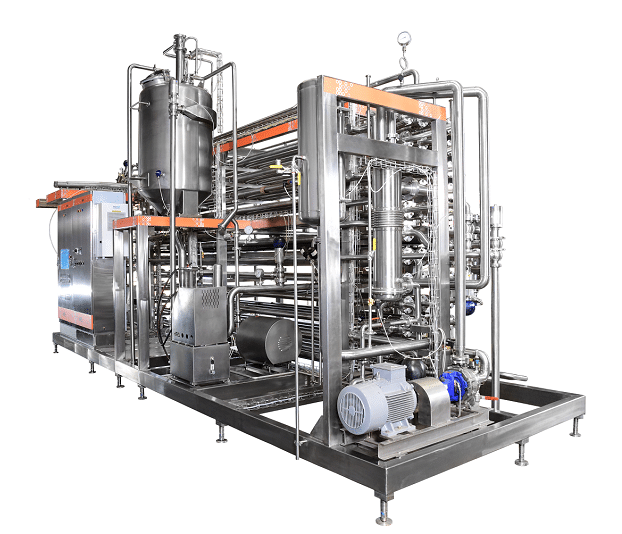

Ideally placed to suit the diverse demands of hygienic applications, the HRS Monobloc is designed to process varying capacities of highly viscous fruit pulp and puree (up to 9000Kg per hour). Configured to meet the most stringent hygiene requirements, the ingenious system incorporates an aseptic steriliser and aseptic filler, seamlessly skid mounted and fully automated with PLC based controls to allow operators to manage their requirements effectively. Featured at the heart of the aseptic steriliser, HRS Ecoflux AS series corrugated tube heat exchangers enable efficient processing of the product at the desired temperature range. The innovative system also boasts a piston pump for homogenising and a de-aerator with automatic vacuum control system supported with CIP pump and peripherals.

Handling pineapple pulp with dices is a specialist process; for which HRS India has recently supplied an HRS Monobloc Steriliser featuring HRS Ecoflux DT Series dimpled tube heat exchangers. HRS DT Series heat exchangers attain high-efficiency rates and allow uniform heating and cooling of the desired product. The system is optimally sized to HTST technology and provides accurate heat treatment; ensuring full compatibility with thermal resistance, pH balance and physical food properties. Full integration of the HRS Piston Pump alongside the HRS Monobloc Steriliser eases processing of dices, whilst maintaining product integrity with minimal shearing. The HRS Aseptic Filler provides a completely aseptic process for filling and packaging pulp with dices in sterile conditions, thus avoiding product contamination.

Our clients have long seen the benefits of our corrugated tube heat exchangers and automated hygienic systems configured within pre-heaters, pasteurisers and aseptic systems. Following the successful supply of HRS’ pulp processing system to a prestigious client based in Tamil Nadu, South India; the team has since supplied its highest capacity HRS Monobloc Steriliser capable of handling 11 tonnes per hour for the same client.

With expectations of a good mango crop earlier in the season and our extensive presence providing proven solutions to overcome various challenges, HRS India continues to strengthen their market foothold within the fruit processing belt of Vijaywada, Chittor and Krishnagiri to name but a few.