Getting the right recipe for heating food products

Heat is fundamental to the food and drink industry. Processes such as cooking, drying and pasteurisation are widely used in all but the most basic food manufacturing and processing situations, in sectors including dairy, fruit and vegetable processing, meat, prepared foods, brewing, dietary supplements and others.

This demand for heating (and cooling) requires a large amount of energy. The Carbon Trust* estimates that the UK’s food and drink sector is the fourth highest industrial energy user in the country, with a total demand of 37 TWh a year, of which up to 60% is attributed to heat.

Minimising environmental impact, maximising profit

In order to reduce their environmental impact and make best use of their by-products and biomass wastes, many food producers have invested heavily in bioenergy production projects such as anaerobic digestion and biomass combustion. While this has helped to reduce the sector’s environmental footprint, maximising process efficiency and thermal efficiencies is sometimes overlooked.

Recapturing and reusing heat from other sources can be an effective way of increasing capacity or adding a new production process without new heating or energy infrastructure. Depending on the application, HRS Heat Exchangers’ equipment has been shown to recover as much as 50% of previously wasted heat, which can then be used for thermal applications.

Influencing factors

While some processes and materials will require specific equipment, such as ovens or retorts, for others heat exchangers are an effective and efficient solution, and are also more likely to enable heat regeneration than other systems. The choice of heat exchanger will depend on many different factors, such as the nature of the process to be carried out (pasteurisation, sterilisation, dehydration, etc.); the viscosity of the food or drink being processed; and whether it contains particles or pieces, etc.

Newtonian and non-Newtonian fluids will behave differently under different temperature and pressure regimes, and this will affect the handling necessary during processing. For example, if subjected to too much pressure, certain sauces may shear, resulting in them failing to meet the end specification. In contrast, certain fat-free products which become more or less viscous with temperature, and so may be more fluid on the cooling side of the heat exchanger than the heating side.

Benefits of corrugation

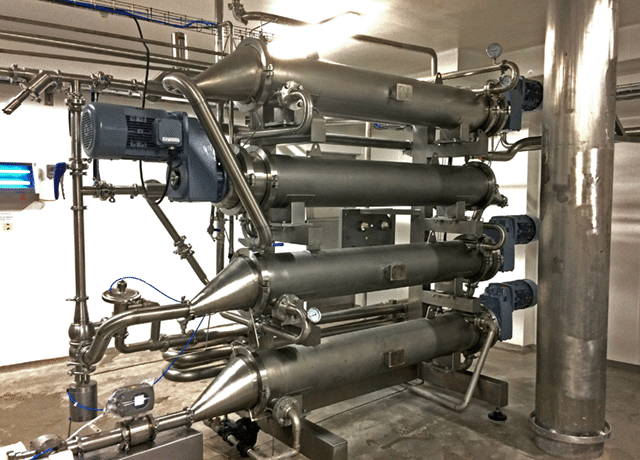

These issues can be overcome with the correct type of heat exchanger and careful system design. Corrugated tube heat exchangers, like the HRS MI and MR Series, can handle delicate materials such as cream without damage. The corrugated design also minimises fouling, increasing thermal efficiency and extending cleaning intervals. Corrugated tube heat exchangers also have a lower pumping requirement resulting in a lower pressure drop, further increasing operation life and reducing maintenance compared with other types of heat exchanger.

Reducing waste

For some materials, such as curd in dairies, increased turbulence can be beneficial. Alternatively, where low pressures are required, scraped surface heat exchangers, like the HRS Unicus Series, keep things flowing smoothly while handling the product gently. Some scraped surface heat exchangers, such as the HRS R Series, can be configured to run in reverse, effectively removing product from the heat exchanger without damaging it or affecting its quality.

Ultimately you need to ensure that the equipment you choose will perform as required. And as with any capital expenditure, it is important to compare not just the initial capital costs, but also operational and maintenance costs across the life of the machinery. Please contact HRS to discuss how we can meet your specific requirements.

* https://www.carbontrust.com/media/39212/ctv004_food_and_drink_processing.pdf