New Juice Processing Solutions: from Concentrate to Bottle – PART 3

Pumping

The smooth and economical pumping of the juice through the system is another important consideration. The HRS BP Series is a purpose-designed, hydraulically operated, reciprocating, positive-displacement pump, with an expanding cavity on the suction side and a decreasing cavity on the discharge side. Material flows into the pump as the cavity on the suction side expands and is forced out of the discharge side as the cavity collapses.

The BP Series features a sanitary design which incorporates a separator fitted between the piston and the hydraulic chamber to ensure that there is no contact between the product chamber and the hydraulic oil. Once the pump is in operation, no part which comes into contact with oil comes into contact with the product.

Aseptic filling

In recent years, aseptic technology has become well established in the food and drink sector as a filling technique. Following pasteurisation, the juice is cooled before cold aseptic filling of the final pack is carried out.

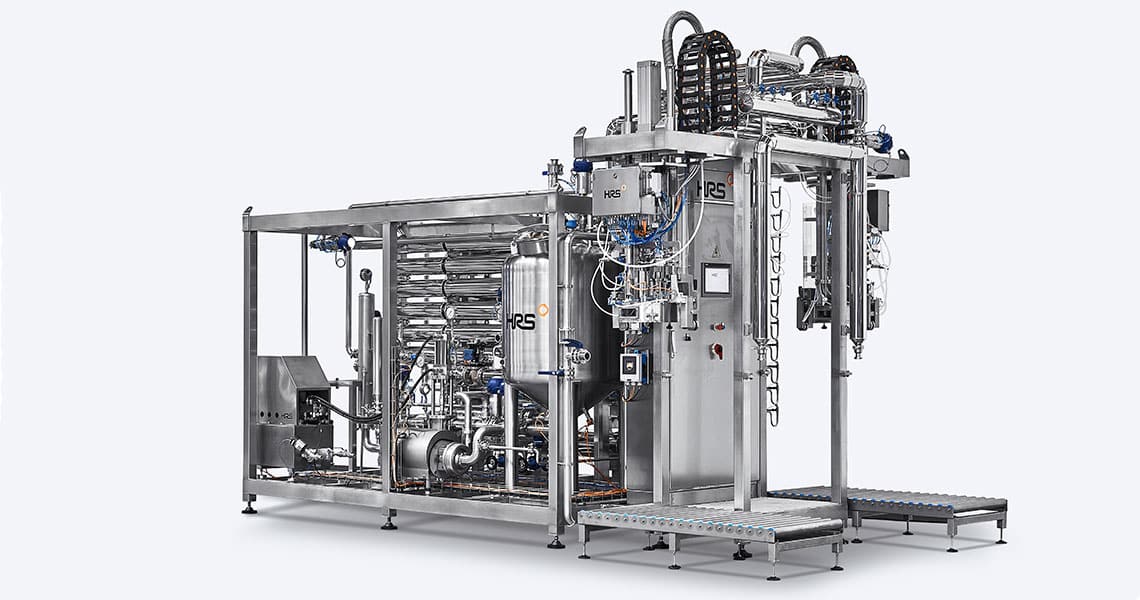

The HRS AF Series Aseptic Filler is designed with one or two automatic filling heads to fill a range of bulk packs between 200 and 1,400 litres. Packaging is presented and removed via a system of rollers and conveyor belts. At the end of each production cycle, the equipment and filling heads are automatically cleaned with CIP solution and the system is re-set ready for the next production batch, avoiding any cross contamination between different products, preserving product quality and maintaining food safety.

Read:

New Juice Processing Solutions: from Concentrate to Bottle – PART 1

New Juice Processing Solutions: from Concentrate to Bottle – PART 2