AD Trials improve Biogas Plant Performance

When it comes to anaerobic digestion, trials can range from making minor changes with the feedstock mix or dwell time, to assessing the effects of major equipment upgrades such as new CHP units or digestate processing equipment.

The level of effort involved in setting up and running a trial can, in many cases, vary according to both the complexity of the subject being investigated and the potential benefits of the changes being made or proposed.

For example, reducing the size of feedstock by chopping it into smaller pieces, or increasing the level of mixing feedstocks before the digester are relatively easy to implement, and may improve gas production or reduce processing times. As such it is fairly straightforward to see if such measures have had the desired effect. However, trying to test large equipment such as digestate treatment units, gas upgrade machinery or new generator sets is much more complicated, although the potential rewards can also be greater.

Trial considerations

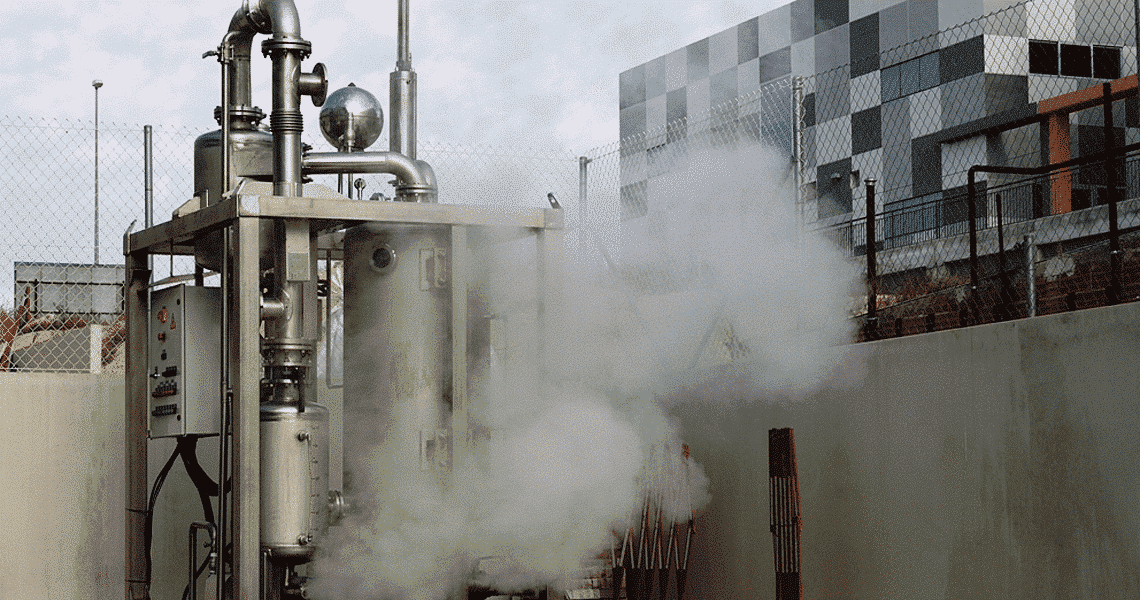

When looking to trial new add-on or replacement equipment ahead of an investment decision, it is easy to become focused on the practicalities of a trial. The first consideration of course is whether or not a realistic trial can be conducted. A number of companies produce small and medium sized trial units of key technology. HRS has a trial version of its Digestate Concentration System (DCS) which allows potential purchasers the opportunity to test our unique system for reducing the amount of digestate produced while increasing its value.

Thinking about logistics: how will you get the trial unit to your site? Where can you locate it? Is there a suitable power supply? Who will manage the project? These are all valid questions which will require answers, but equally important is the design of the trial itself. After all, there is no point in investing large amounts of time and effort if you fail to obtain answers to your main queries or, in the worst case, fail to even to know what you hope to find out.

Know your objectives

The first step is to talk to the company involved. Make sure you know what the unit is designed to do and that it is suitable for what you want. There is no point testing something which reduces your electricity use by 10% if you are really after something that exports heat for an outside process.

Having made sure that what you will be testing should do what you want it to, the next step is to work out what exactly you expect it to do and how you can measure it. For example, the DCS provides a number of benefits including increasing the solids content of the digestate, reducing overall digestate volumes and improving nutrient content. In the case of a new radiator it may be that running temperatures at the CHP are reduced, improving generator efficiency and reducing the number of oil changes needed. It would therefore be more useful to measure exported power and the physical properties of the oil than to keep an eye on running hours.

Measure the results

Once you know what you need to measure, you need to know how to do it, and also to measure what you have been doing to give you a suitable comparison. If you don’t know how much liquid digestate your plant currently produces in a given period, how will you know if it has been reduced?

Most trials carried out in the industry will be comparison trials, such as ‘before’ and ‘after’ or, depending on plant configuration, perhaps trialling two different practices alongside each other or alternately over a period. While such a setup may not be ideal from a purely scientific or statistical point of view, in most cases they should be robust enough for practical purposes. When combined with regular monitoring or scientific analysis (for example a nutrient analysis on digestate produced with and without passing it through the DCS) they should provide sufficient confidence to tell you whether or not the changes you are proposing will work and to inform the appropriate investment decisions.

It is easy to be overwhelmed by the process of setting up trials but you will find that most manufacturers and suppliers are only too happy to help demonstrate the effectiveness of their equipment, subject to logistical constraints. As a first point of call, feel free to contact us for further information of how the HRS trial DCS unit has been used in the past and how it could help your own AD process.