PUMPS

Many years of working with difficult heat transfer solutions in the food industry has proved that pumping products without destroying their integrity is as important as developing heat exchange solutions which maintain product quality.

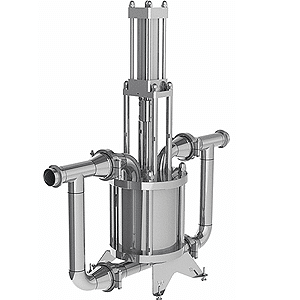

This led to the development of the HRS piston pump which is designed to handle very delicate and viscous food stuffs. Pumping up to very high pressure without damaging the food particles is not a problem. The pump has also been applied successfully in heavy duty applications for other industries than food.

Traditional pumping systems for particulate products can cause problems for food processors who needed to pump whole fruits or vegetables or pieces. Problems arise not only because of the high costs of traditional pumps but also because lobular pumps have low flow rates. In addition, using progressive cavity pumps can break the produce, while double diaphragm pumps result in a low pressure drop.

To overcome these problems, HRS Heat Exchangers has developed a sanitary reciprocating positive-displacement pump, (the BP Series Piston Pump) that provides the following benefits:

- Consistent product identity

- Gentle product treatment

- High flow rates (up to 88 gpm)

- High pressure (435 PSI)

- Can run dry

- Minimal spare parts

- High temperatures (248°F)