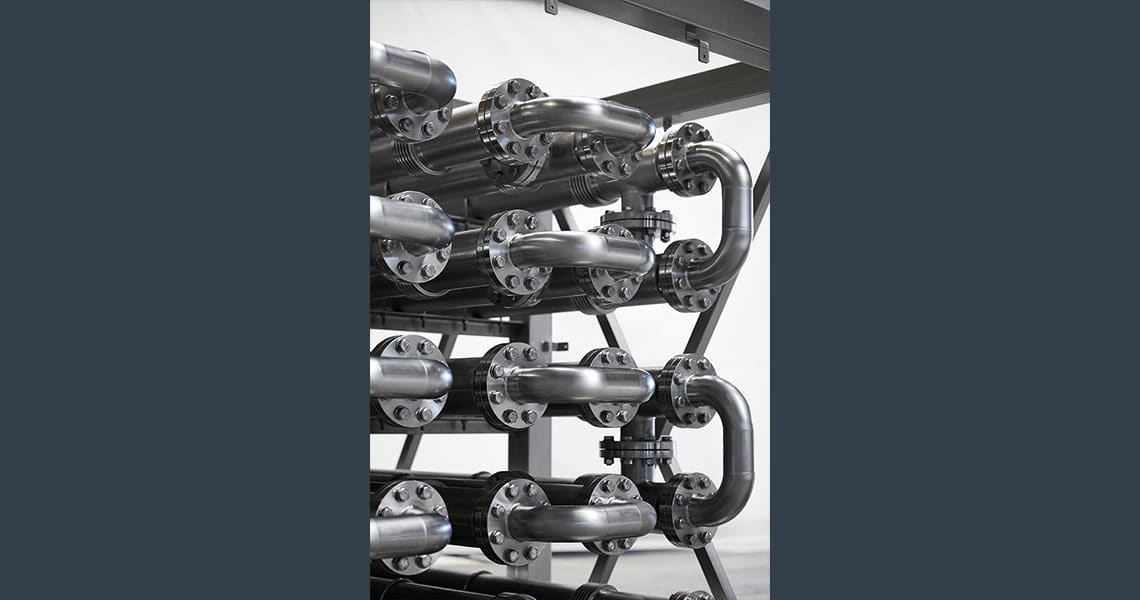

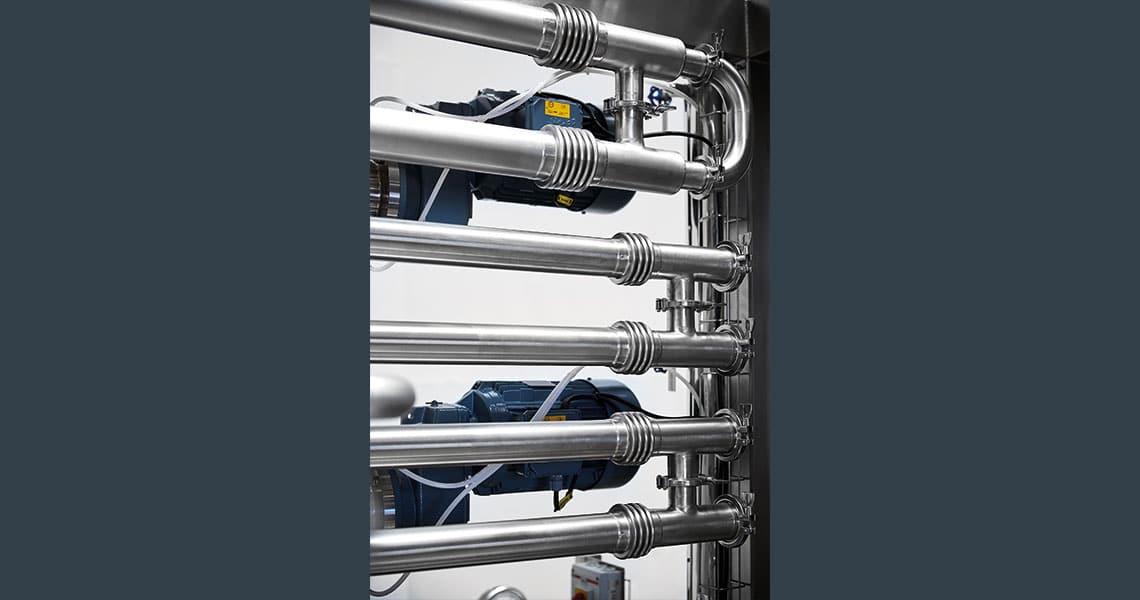

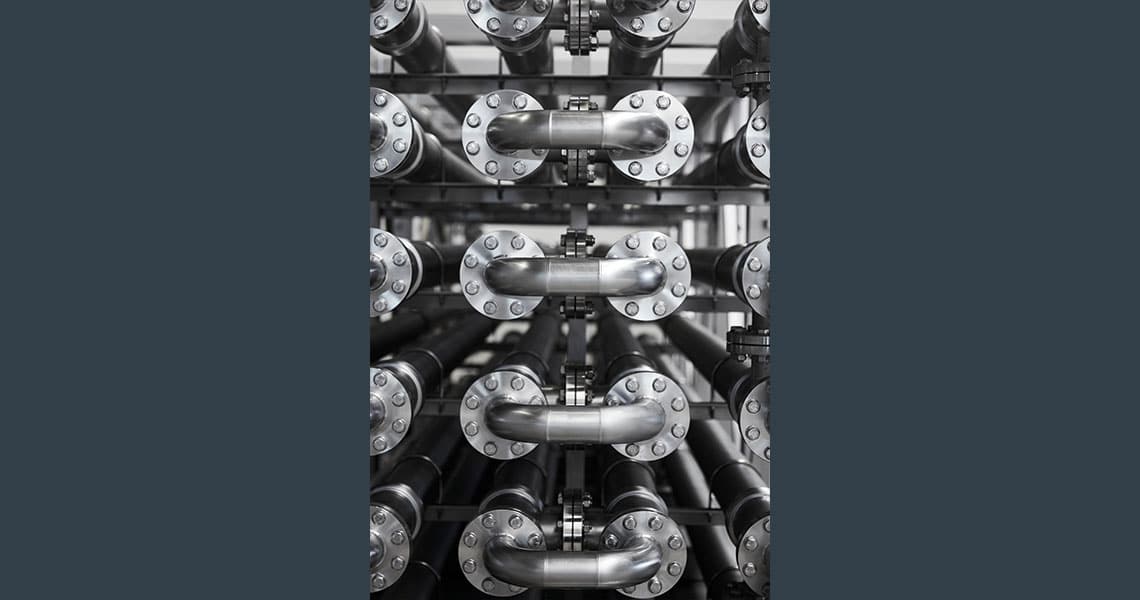

Double Tube Heat Exchangers

A double tube, or tube-in-tube, heat exchanger is used for efficient heat transfer between two fluids.

Double tube heat exchangers are designed whereby one tube is concentrically positioned within a larger tube. The double tube composition allows for unrestricted flow of product, making it the ideal heat exchanger for viscous products. The product flows through the inner tube and the service fluid flows through the surrounding shell.

HRS offers three types of double tube heat exchangers for a variety of applications:

- Hygienic Double Tube Heat Exchangers – HRS DTA Series

- Industrial Double Tube Heat Exchangers – HRS DTI Series

- Industrial Double Tube Heat Exchangers with Removable Tube – HRS DTIR Series