Petrochemicals

The petrochemical industry has many requirements for heat exchangers, with different processes requiring different techniques, including plate heat exchangers, such as the HRS PHE Series and tubular heat exchangers.

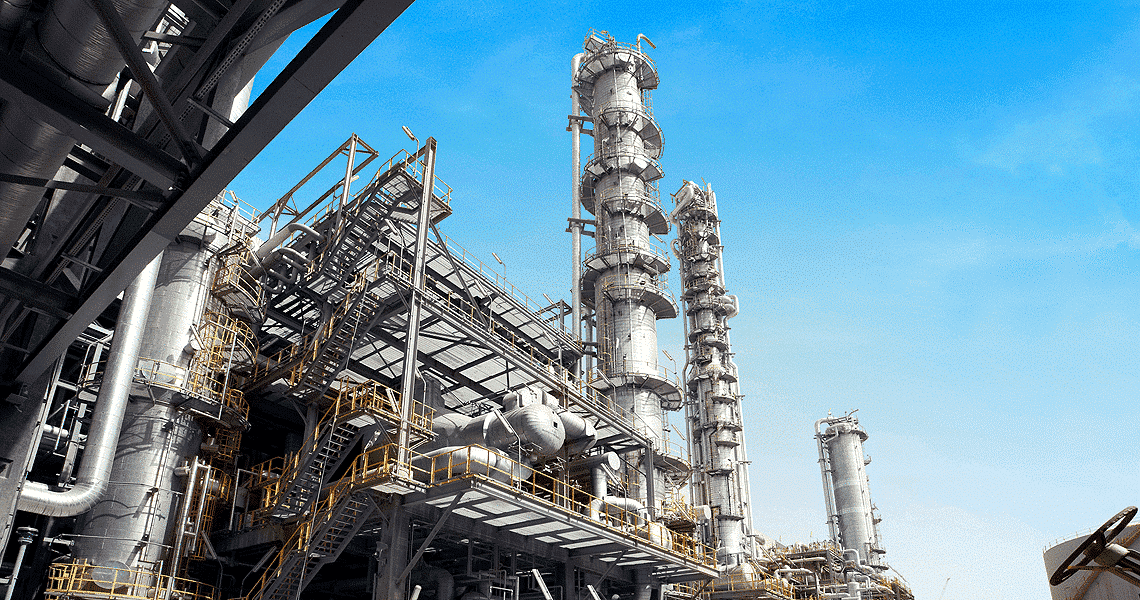

High pressure and high temperature are typical requirements of heat exchangers used in the petrochemical sector, both on- and offshore. Crude fossil fuels contain large quantities of water and much of the process is devoted to removing this from the finished products. Further on in the process heating, cooling and distillation operations are all crucial, as is energy recovery to maximise product efficiency.

In many situations, particularly offshore and in remote locations, space is at a premium and HRS heat exchangers can be configured to provide maximum heat transfer for a minimal footprint, while maintaining the safety concerns associated with flammable, explosive or corrosive substances.

As well as their use in extraction and refinery operations, heat exchangers are commonly found throughout the petrochemical supply chain for processes including cleaning, liquefaction, condensation and regasification.

Typical applications of heat exchangers in the petrochemical industry include:

- Condensation of solvents and other chemicals

- Cooling and heating of reactors, production units and intermediate products

- Cooling of hydrocarbons and water

- Heat recovery from materials and processes

HRS Heat Exchangers’ products for petrochemicals include:

- Scraped Surface Heat Exchangers: HRS Unicus Series

- Multitube Heat Exchangers: HRS K Series

- Mutipass Heat Exchangers:HRS MP Series

- Double Tube Heat Exchangers: HRS DTI Series

- Plate Heat Exchangers: HRS PHE Series