Pasteurization of Sludge

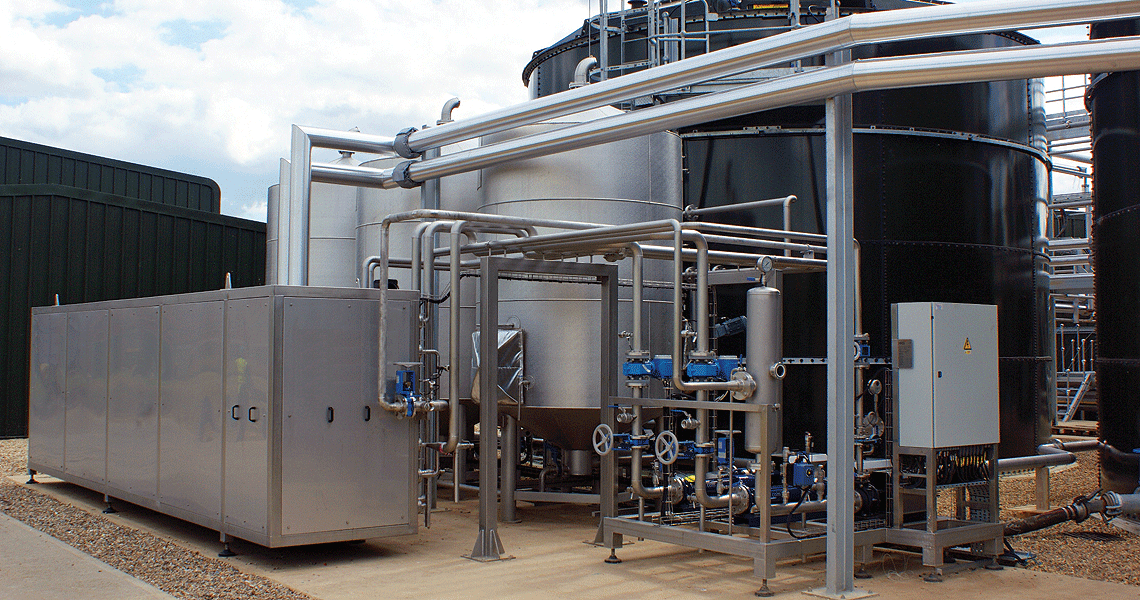

The heating and concentration of wastewater streams and sludge are an essential process in many industries, not just water treatment. Pasteurization of sewage sludge and digestate (biosolids) to make them biologically safe for further processing, disposal or use is a key process.

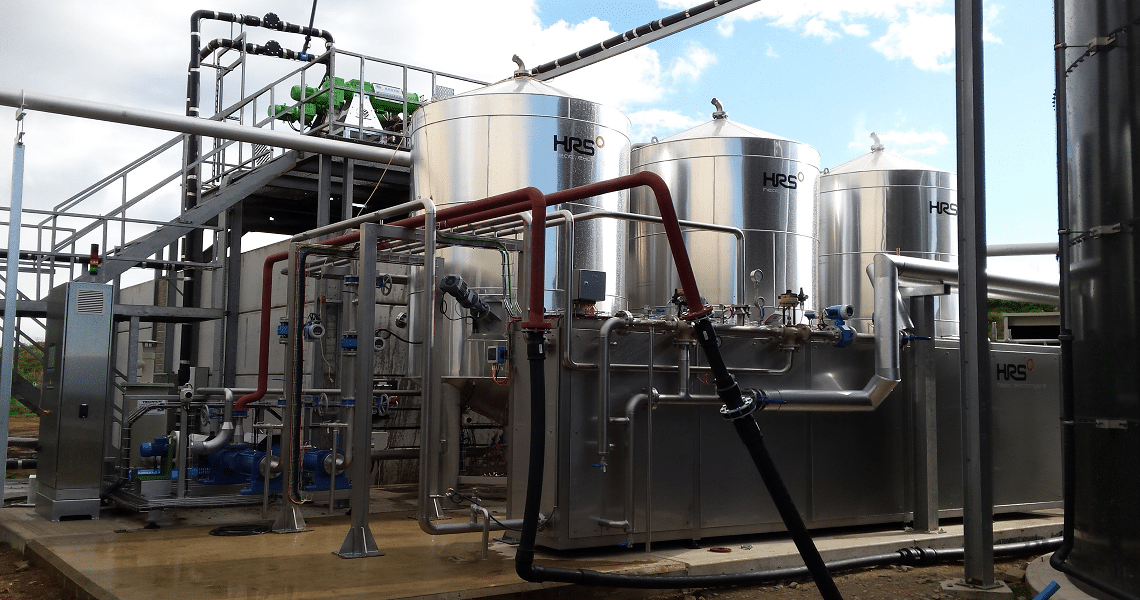

Two common issues with some other sludge pasteurization systems are their inherent inefficiency and fouling of the heat exchanger tubes due to the nature of the sludge or wastewater material. HRS Heat Exchangers overcomes the fouling issues by using its corrugated tube in tube technology as found in our DTI Series, together with cleaning-in-process (CIP) technology where necessary.

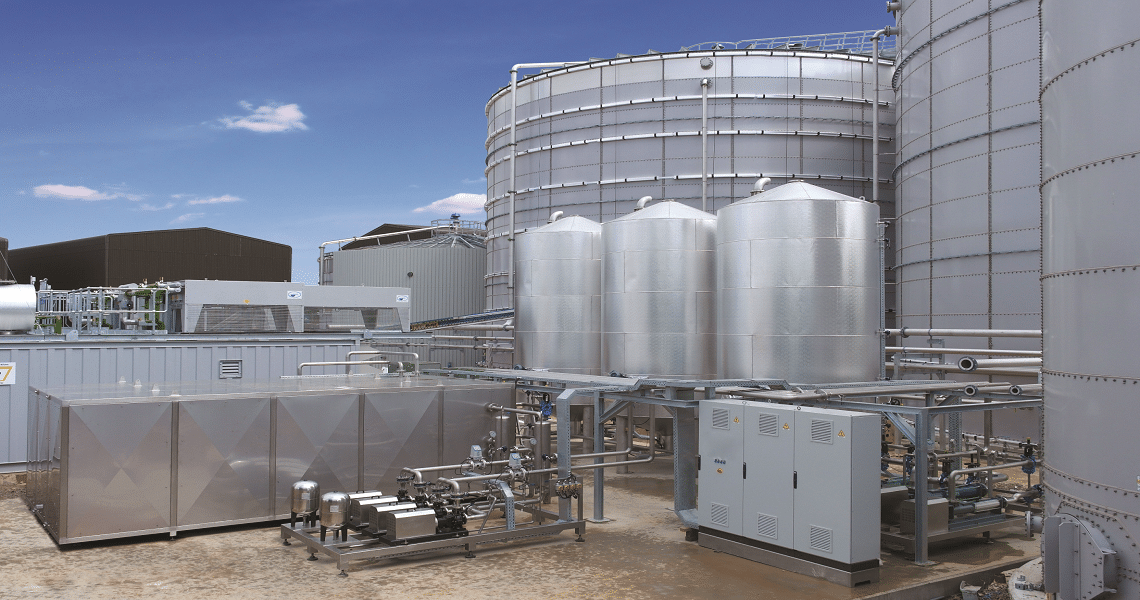

More importantly, we produce dedicated multi-tank sludge pasteurization systems (DPS) which offer numerous benefits over other systems. As well as reducing fouling and keeping maintenance requirements to a minimum, HRS pasteurization units recapture the energy used in the cooling section of the heat exchanger for use in the initial heat up. This means that HRS sludge pasteurization units are up to 70% more efficient than the traditional single tank ‘heat jacket’ pasteurization systems.

Using multiple tanks in our digestate pasteurization system means that pasteurization does not slow down your overall process. One tank can be filled (or filled and emptied) while another is holding the sludge at the correct pasteurization temperature for the required amount of time.

HRS DIGESTATE PASTEURIZATION SYSTEMS ARE SUITABLE FOR THE FOLLOWING APPLICATIONS:

Environmental applications:

- Wastewater treatment

- Sewage sludge and biosolids treatment

- Other effluents

Bioenergy applications:

- Biogas feedstock pasteurization

- Pasteurizing digestate from biogas production

Food & agricultural applications:

- Pasteurizing food and agricultural wastes