Digestate Pasteurization for Renewable Energy (DPS)

The HRS DPS Digestate Pasteurization System has been specifically designed to meet the requirements of pasteurization in the anaerobic digestion and renewable energy sectors. The DPS is capable of pasteurizing digestate, feedstocks, sludge and similar materials and is suitable for both pre-and post-digestion pasteurization, allowing operators to maximize the efficiency of their overall process while meeting regulatory requirements such as PAS110 and Animal By-Product (ABP) regulations used in the UK, systems can be designed in accordance with global standards.

The numerous benefits of the HRS DPS system include:

- Designed to Global Standards compliance such as PAS110 and ABPR in the UK – End product free from plant pathogens or other biological contaminants

- Provides up to 60% heat regeneration – the DPS is extremely energy efficient;

- Traceability – Batch reporting allows operators to track and trace digestate batches

- The DPS is completely flexible and can be tailored to suit each individual operation.

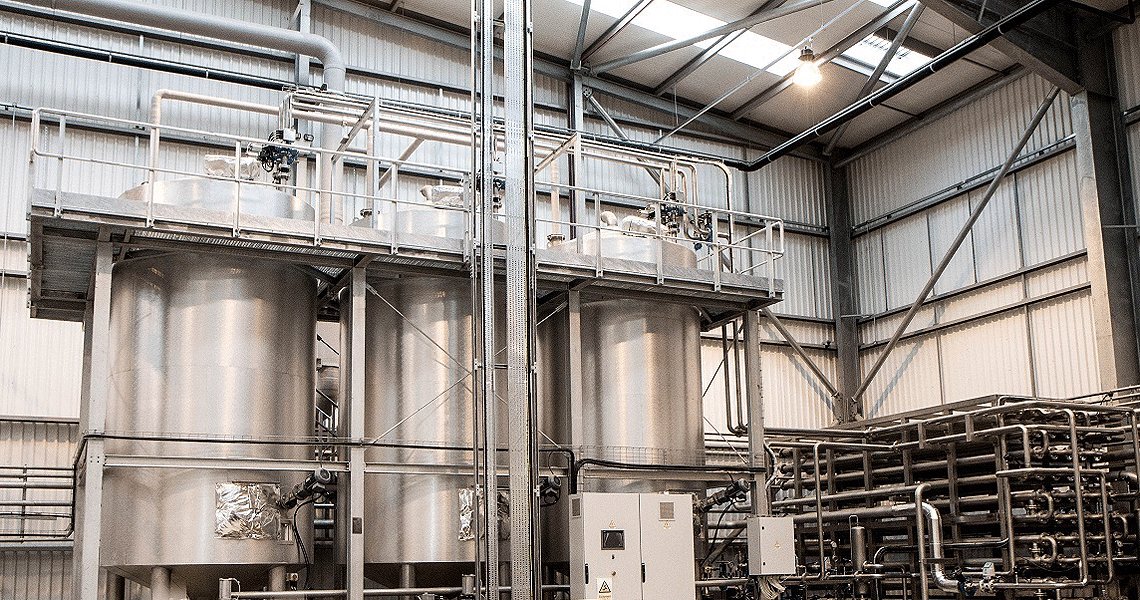

The HRS 3 tank DPS allows the contents of one tank to be pasteurized while one is emptying and one filling, ensuring that the process does not slow down overall throughput. Therefore, it is ultimately a simpler solution than a single tank option which may require buffer tanks and additional controls to restrict flow elsewhere in the process.

The DPS is designed to work effectively with the specific characteristics of digestate, such as suspended solids, there are solutions for almost any material. HRS innovations such as the use of corrugated tube and scraped surface heat exchangers means that we can deal with anything from viscous fluids requiring gentle handling or with low rates of heat transfer, to complex mixtures, such as digestate, which would otherwise foul the heat exchanger reducing thermal efficiency and requiring regular cleaning and maintenance.

Traditional single tank pasteurization units simply dump this heat afterwards, meaning they are incredibly wasteful and inefficient. In contrast, HRS heat exchangers recapture the heat and use it again, making them up to 70% more efficient than traditional single tank ‘heat jacket’ type pasteurization systems.