Rotating Scraped Surface Heat Exchangers – HRS R Series

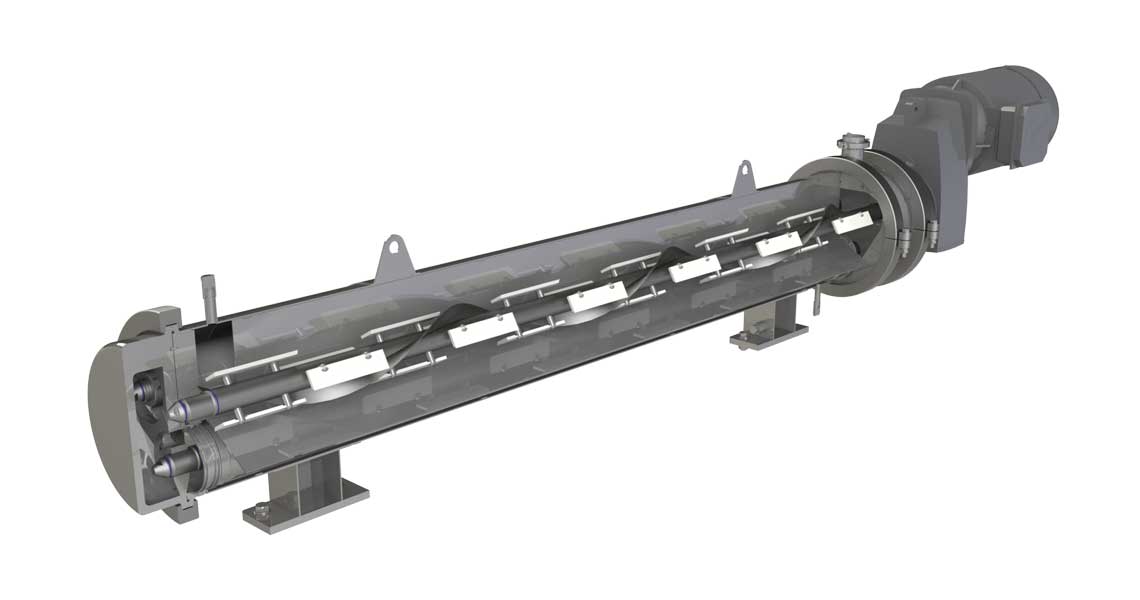

The HRS R Series is a scraped surface heat exchanger designed for the most difficult heat transfer applications, for example where very high viscosities and highly fouling fluids need heat treatment.

Unlike the HRS Unicus Series, where the scraper movement is reciprocal, the HRS R Series technology uses a rotary scraper rod. This scraper rod can reach velocities up to 300 rpm resulting in very high levels of shear and mixing at the heat transfer surface; dramatically increasing the heat transfer rate.

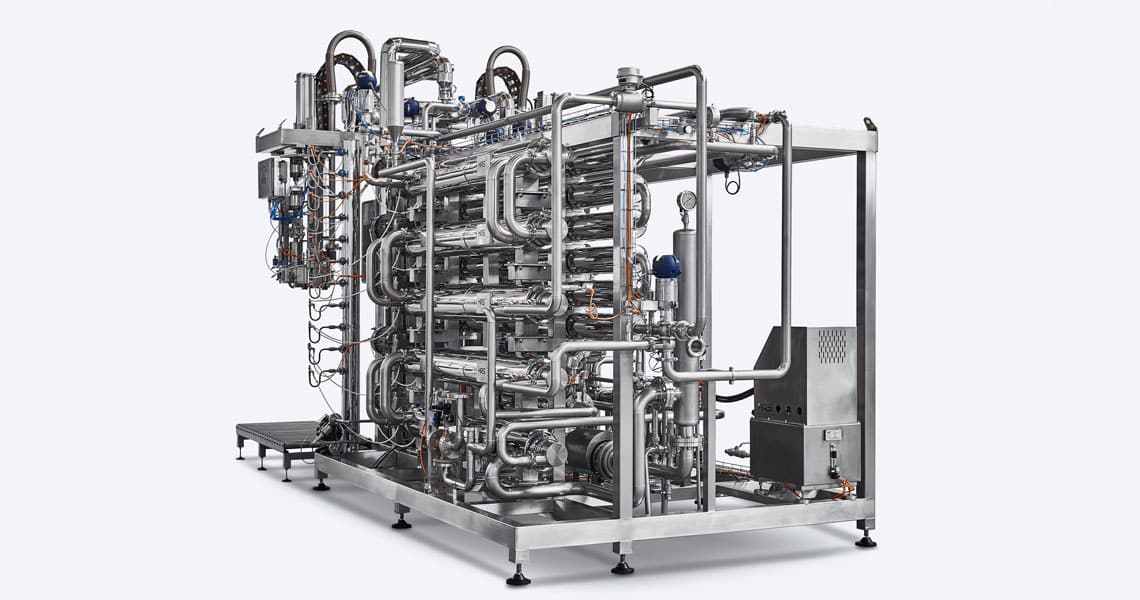

In addition to the standard R series a heavy duty version is available. The HRS RHD Series has been developed for the more demanding applications with extreme viscosities. The RHD has all the features and benefits of the standard R Series but with increased motor size and scraping rods. Extra mounting supports for the scrapers and motor enable the unit to be used under challenging conditions.

The R and RHD Series has been developed for both hygienic and industrial applications. Each inner tube contains a scraper bar fitted with a helical screw which rotates at high speed and enhances flow through the tube whilst reducing pressure drop. In addition, the continuous scraping action eliminates fouling on the inner tube wall, ensuring that the heat transfer area is clean at all times.

Some of the unique features of the R and RHD Series include:

- Large heat transfer area

- Single and multiple tube options, all with removable tubes

- Reduced pressure drop

- High level of product recovery

- Low noise level gearbox

- Energy Efficient

- Multipass version available

GEARBOX SYSTEM

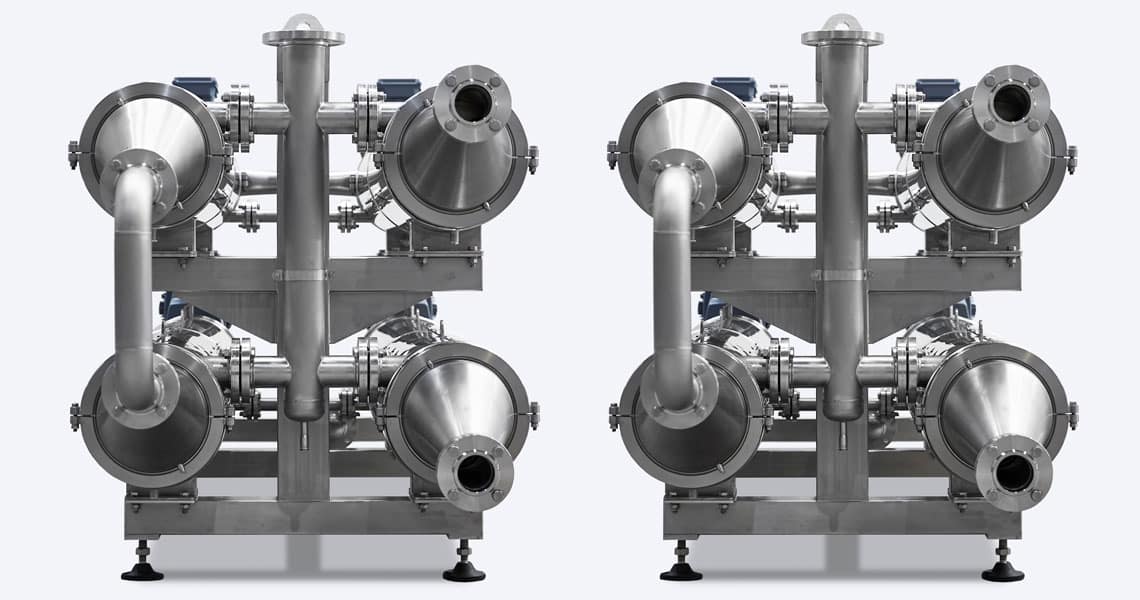

Unlike other rotating scraped surface heat exchangers, the HRS R Series can use up to six heat transfer tubes in a single unit. This is made possible using a uniquely engineered gearbox system which transfers the energy of a single electrical motor to the scraper rods in each individual tube. In this way, a greater surface area can be fitted in a single unit. The gearbox design also gives the benefit of low noise level during operation due to the materials of construction.

UNIQUE SCRAPER BAR SYSTEM

A spiral blade is fitted to the scraper rod. The rotating movement of this blade helps to push the fluid forward. This way, high viscous fluids are pumped through the HRS R Series more easily resulting in less back pressure.

UNIQUE BAFFLE PLACEMENT

The design of the HRS R Series allows one or multiple heat transfer tubes to be fitted into one single heat exchanger shell, increasing the size of the shell-side cross section. If the liquid shell-side flow is limited then velocities, and therefore heat transfer, are reduced on the shell side. To improve this, longitudinal baffles are fitted to separate the fluid paths in the shell; acting as an individual compartment for each heat transfer tube. The flow cross section is reduced and velocities increase, maintaining heat transfer rates. For multipass designs, complete counter-current flow between the shell side fluid and tube side fluid can be obtained.

In case of condensing (for example steam heating) or evaporating (for example ammonia cooling) fluids, the units can be designed without longitudinal baffles for better performance.

REMOVABLE INNER TUBES

The R and RHD Series are fitted with removable inner tubes; ensuring easy inspection and maintenance, significantly reducing operational costs.

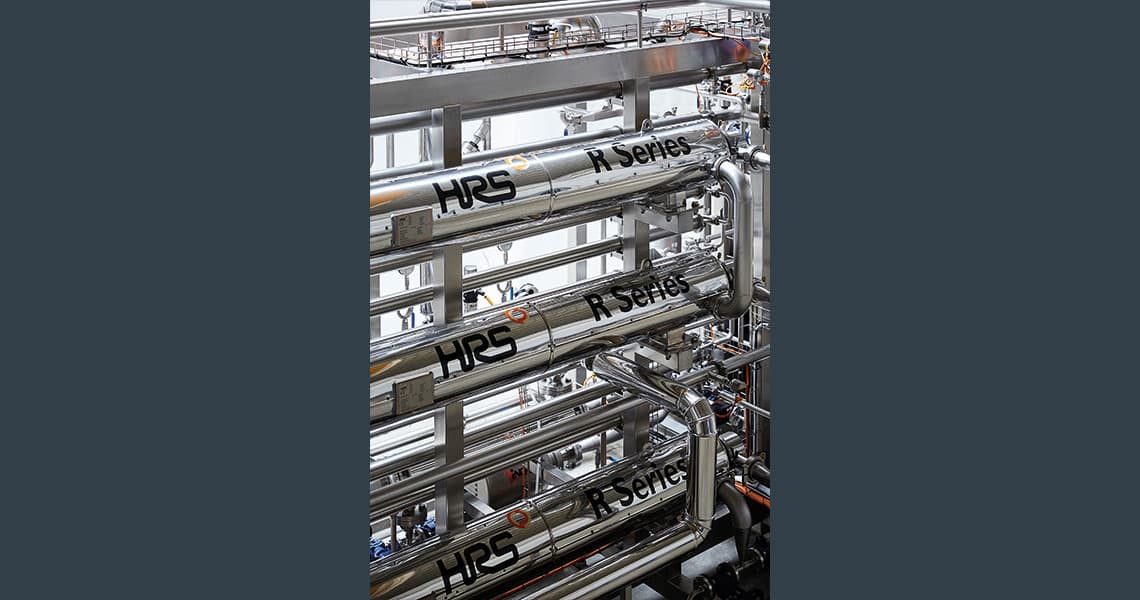

HRS R SERIES: A SCALABLE SOLUTION

The R series comes in three versions, each version in tube lengths of one or two meters:

- HRS R 1: Tube in tube version: heat transfer areas from 4 to 8 ft².

- HRS R 3: Three tube version: heat transfer areas from 11 to 22 ft².

- HRS R 6: Six tube version: heat transfer areas from 23 to 45 ft².

The R and RHD Series are suitable for heat transfer applications on a wide range of products and applications:

Products:

- Viscous food products: Dairy and vegetable concentrates (condensed milk, tomato paste, purees, juice concentrates, honey, butter, margarine), nut butters

- Convenience foods: Chocolate-based dressings, ketchup, cheese sauce, spreads

- Protein: Egg-based products, minced meats

- Cosmetics: Lotions, cream, gels

Processes:

- Heating

- Cooling

- Pasteurization

- Crystallization

- Evaporation

TECHNICAL DATA

Designed in accordance with ASME

Standard Materials of Construction:

- Service side: AISI 304 stainless steel

- Product side: AISI 316L stainless steel

All other material options available

Standard Connections:

- Service side: Flange

- Product side: Clamp

All flange & clamp types available

Surface Finish:

- Exterior: Polished

- Interior: <0.8μ

Design code and compliance:

- PD 5500, PED 2014/68/EU, 2014/34/EU (ATEX), 2006/42/CE, ASME

- FDA, 3-A, TR CU 032, DOSH Compliant