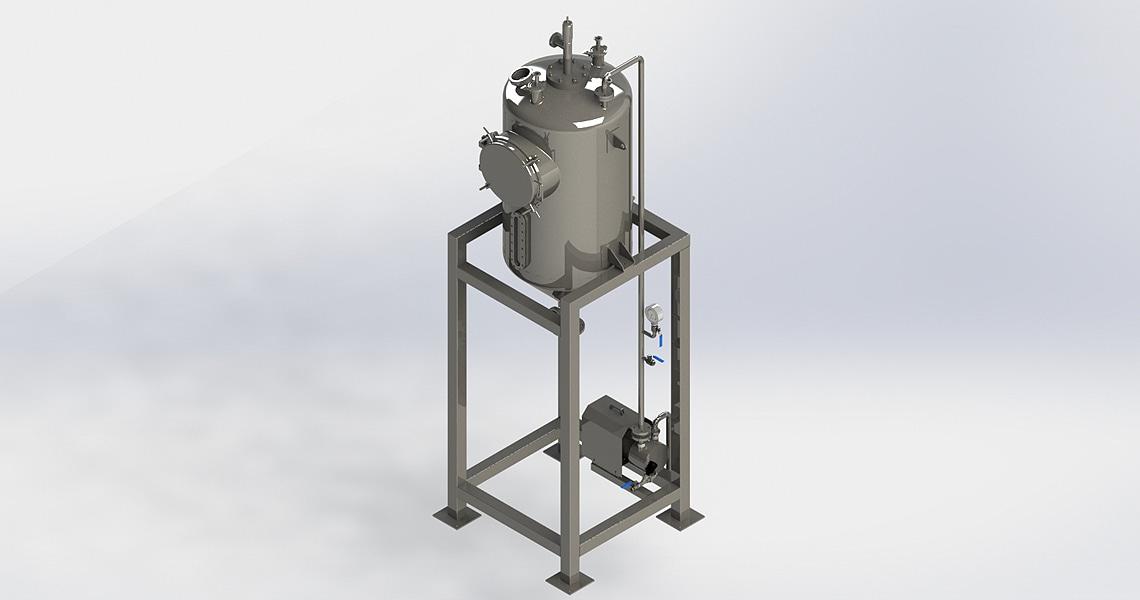

Air Removal (Deaeration) Systems

Deaeration is principally intended to remove any air present in the material to be processed. The presence of air in many food products encourages oxidation and may be detrimental to product life or quality, in many cases it can increase thermal resistance and heating load.

HRS has developed an air removal (deaeration) module which can be fitted into the production line before thermal treatment takes place.

For these HRS developed an air removal (deaeration) module which can be fitted into the production line before thermal treatment takes place. The principal components of the air removal module include:

- Automatic valves: Product inlet from the atmospheric storage in the line (also included is water inlet for rinsing and flushing and CIP cleaning); return from the sterilising section.

- Manual valves: Product pump feed, deaerator drainage.

- Vibratory Level indicator: To give the minimum safe working level for the product pump.

- Proportional level indicator: To measure the level of product within the tank continuously.

- Cleaning Head: For distributing the CIP solutions within the vessel.

- Access Cover: For maintenance operations and internal inspections of the deaerator, etc.

- Pressure sensor: To control the vacuum generated in the interior of the vessel.

- Sight glasses: for visual inspections.

- Vacuum line: Aroma condenser, liquid ring vacuum pump, manual vacuum break, vacuum gauge, etc.

AIR REMOVAL SYSTEM FUNCTIONS

Working under vacuum, the deaerator pulls the air and/or other volatile components which could have entered to the surfaces of the product.

The product enters through an automatic valve and a condenser is included in the upper part to recover aromas and other volatile organic compounds which are returned to the vessel by gravity and reincorporated into the product. The level of vacuum is controlled automatically by an electronic pressure sensor and the condenser is cooled using chilled water. The aroma condenser is based on an MI Series corrugated tube shell and tube heat exchanger.

The deaerator also acts as a buffer tank for the product, regulating the flow to the production line. The flow rate can be adjusted and a flow-meter is installed to give precise control.

In order to achieve effective CIP cleaning a centrifugal CIP pump is fitted in series with the product pump. Beyond the product pump a safety valve is fitted to prevent over-pressurisation of the processing line, a pressure gauge and thermometer are also fitted before the product heating section.

The Air Removal (Deaeration) system includes the following components:

- Deaerator vessel

- Helicoidal positive displacement pump

- Centrifugal CIP pump

- Aroma condenser

- Liquid ring vacuum pump

- Electromagnetic flow meter

- Valves and instrumentation