Concentration and Evaporation Systems

HRS evaporation systems are designed for concentration of products from juices and purees to tomato and liquid cheese based products. Application dependent, we use our corrugated tube or Unicus scraped surface heat exchangers as the evaporator, in a forced recirculation setup. Multiple effect systems or use of mechanical or thermal vapor recompression can be supplied, increasing savings.

HRS applies two heat transfer technologies within its evaporation systems:

Corrugated Tube Evaporation Systems

Using the K Series as an evaporator module for the evaporation of low viscosity effluents with small particulates high heat transfer and good resistance against fouling.

Applications: fruit pulps and purees or products with organic solids in low concentration and up to medium viscosities.

Scraped Surface Evaporation Systems

Using the Unicus Series as an evaporator module for high fouling fluids with elevated viscosities. When concentrating to a high dry solid percentage the risk of fouling and high viscosity (low heat transfer) become apparent. For these applications, the Unicus is ideal due to its self-cleaning scraper design.

Applications: Liquid cheese and sauces with high fouling risk and organic solids with high dry matter content.

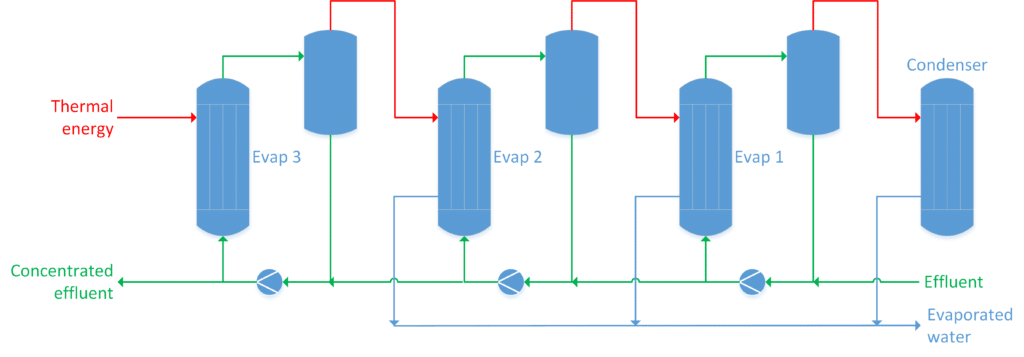

MULTI-EFFECT EVAPORATION SYSTEMS

Three-Effect Evaporation Scheme

These systems combine various evaporation stages. The vapor obtained from a previous stage is used as the thermal energy source for the resulting stage. Multiple stages can be combined to reduce the energy consumption needed for the amount of water evaporated.