Concentration and Evaporation Systems

Evaporation is an efficient way of reducing the volume of effluents and wastes. Our evaporation systems raise effluent to its boiling point so that water is evaporated and then condensed, thus obtaining a concentrated end product and water. Forced recirculation uses a pump to send the product through the evaporator at high speeds, ensuring high velocity, good heat transfer and minimal fouling.

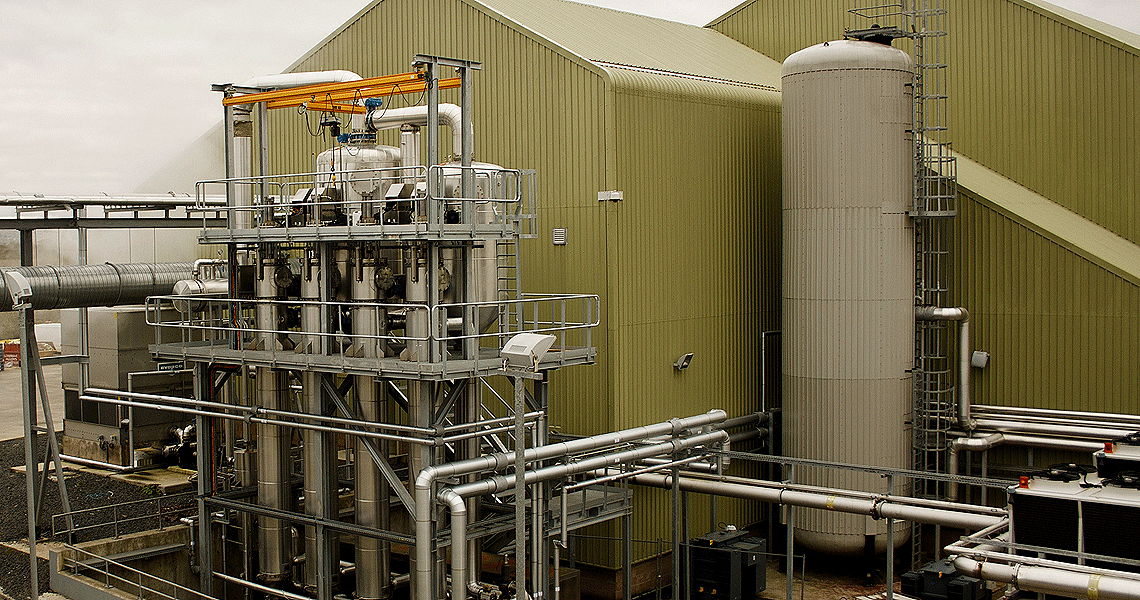

Where possible we aim to integrate our evaporation systems with waste heat sources to achieve an effective sustainable process.

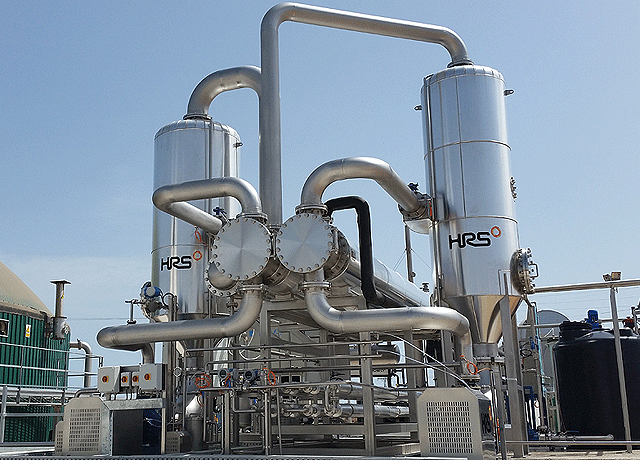

CORRUGATED TUBE EVAPORATION SYSTEMS

For the evaporation of low viscosity effluents with reduced particle size we use the K Series heat exchanger as an evaporator module, providing high heat transfer and good resistance against fouling.

Applications for these systems include:

- Wastewater

- Brines and effluents with organic solids in low concentration

- Effluents with low to medium viscosities

- Low suspended solids

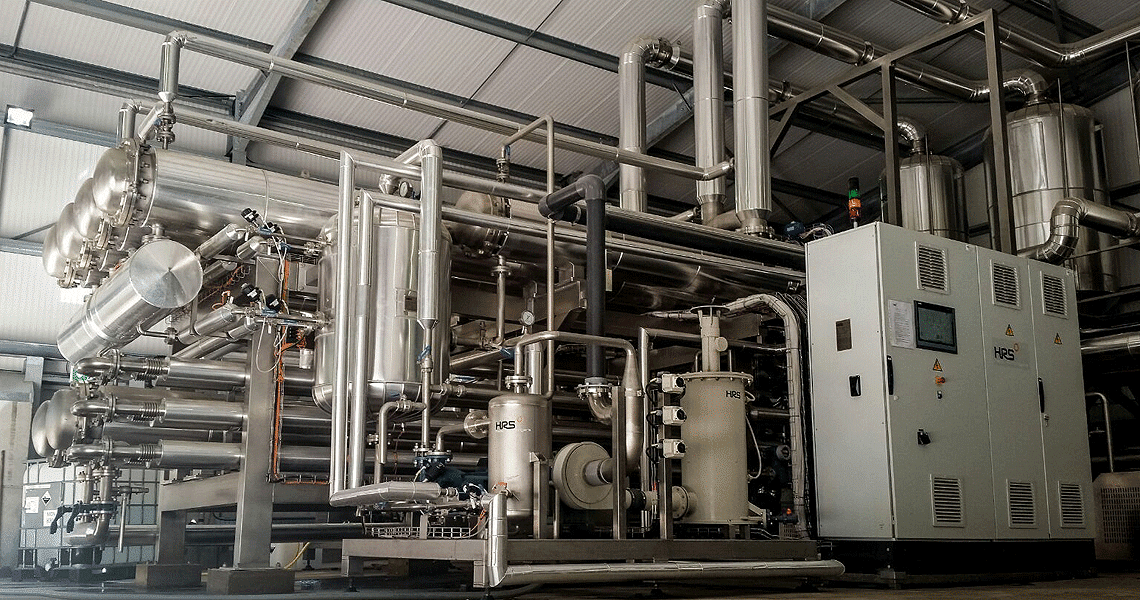

SCRAPED SURFACE EVAPORATION SYSTEMS

HRS recommends the Unicus Series as an evaporator module for high fouling fluids with elevated viscosities. When concentrating materials to a high dry solid percentage, the risk of fouling and high viscosity (which lowers heat transfer) becomes apparent. For these applications, the Unicus Series is ideal due to its self-cleaning scraper action.

Applications include:

- Effluents with high fouling risk

- Organic solids with high dry matter concentration

- High suspended solids

HRS uses two technologies that maximize energy usage within our range of evaporation systems:

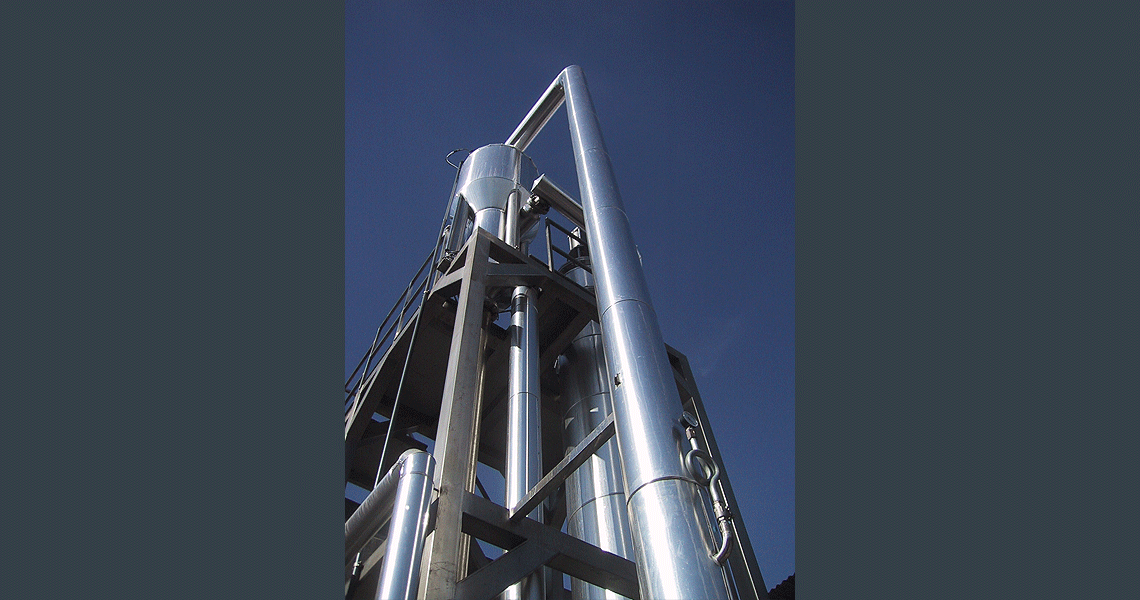

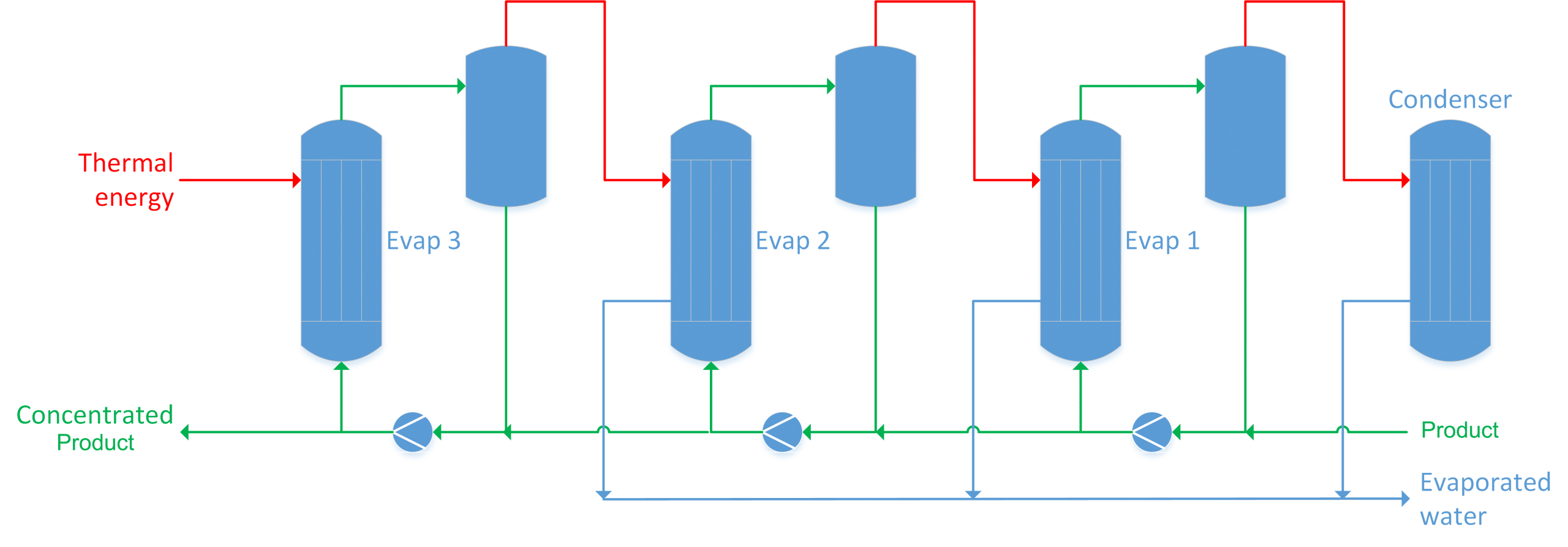

MULTI-EFFECT EVAPORATION SYSTEMS

Three-Effect Evaporation Scheme

These systems combine various evaporation stages. The vapor obtained from a previous stage is used as the thermal energy source for the resulting stage. Multiple stages can be combined to reduce the energy consumption needed for the amount of water evaporated.

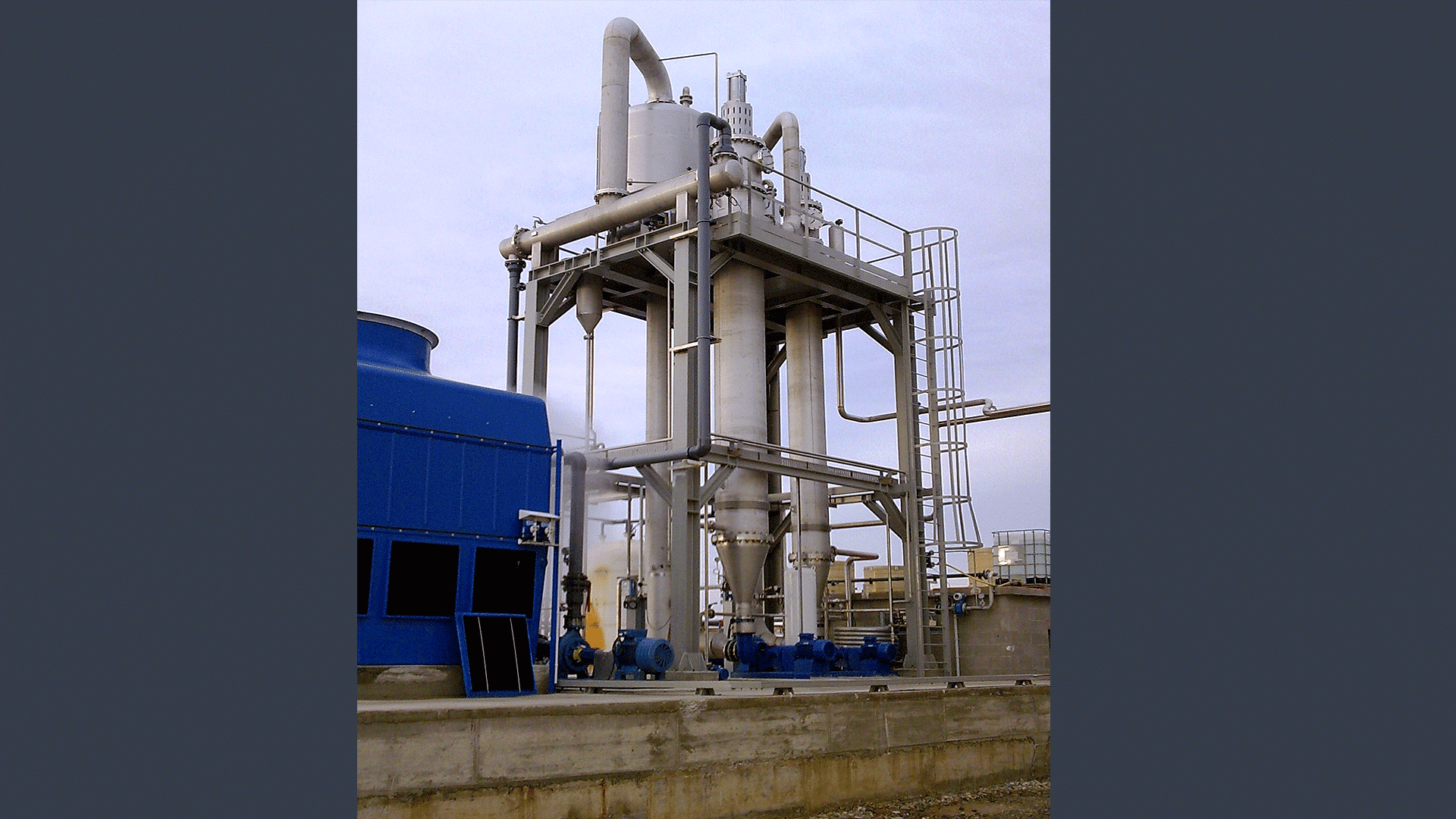

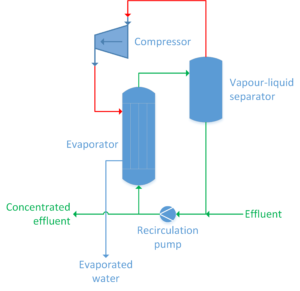

MECHANICAL VAPOR RECOMPRESSION (MVR) OR THERMAL VAPOR RECOMPRESSION (TVR) SYSTEMS

In MVR setup, the evaporated steam is sent to a compressor (where it increases in pressure and temperature) and used as the thermal energy source in the evaporation process. Only electrical energy (for driving the compressor) is used in this setup. In TVR setup, boiler steam can be mixed with evaporated steam in a thermo-compressor, leading to considerable energy savings.

Each evaporation system is designed specifically for its application.

HRS offers evaporation solutions for:

- Effluents

- Wastewater

- Brines

- Digestate

- Sludge

- Manures

- Palm Oil Mill Effluent (POME)