Busting the Myths about AD Pasteurization

Whether to add pasteurization to an anaerobic digestion plant can be a contentious topic in certain circles. While there are undoubtedly benefits, including compliance with the PAS 110 standard for digestate, many plant operators and those considering biogas project see pasteurization as adding unnecessary cost and complexity to the process.

However, six years of supplying pasteurization and heat exchange equipment to the AD sector has convinced me that, while not a necessary step for everyone, pasteurizing of either feedstock or digestate can be a useful and cost effective method of improving or ensuring product quality. The reason that it is not always perceived as such tends to be due the following eight popular misconceptions or ‘myths’, which we tackle here:

Myth 1: Pasteurization is expensive

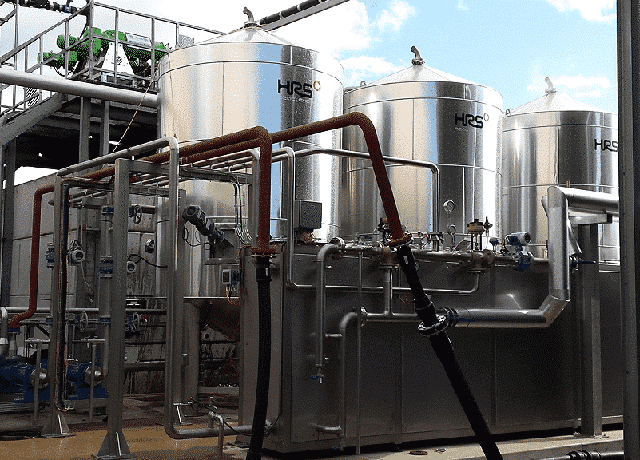

While the exact costs will vary with each installation, there is no doubt that the capital costs are not insignificant. For example, an HRS 3-Tank Batch Sludge Pasteurizer designed to treat 80-85,000 tonnes of digestate a year could have a capital cost around £450,000 (USD $595,000) depending on specification. While not an inconsiderable sum of money, there are multiple managerial and quality benefits of pasteurization, while in pure economic terms, the experience of industry is that treated digestate is worth more than untreated material.

Alongside the capital costs, the running costs of a pasteurization unit need to be considered. All HRS heat exchangers and pasteurization units are designed to reduce fouling and maintenance while our wide range of heat recover options mean that energy costs are kept to a minimum (see below).

Myth 2: Pasteurization is too complex

Pasteurization itself is a relatively simple process. It requires that a material is held for a certain time at a certain temperature in order to kill microorganisms. There is no doubt that pasteurization adds an additional step in the overall AD process, but if well designed, technology should not slow down throughput or place additional management burdens on the plant.

For example, the HRS 3 Tank Batch Sludge Pasteurizer has three tanks allowing one to be pasteurized while one is emptying and one filling, ensuring that pasteurization does not slow down overall throughput. Therefore, it is ultimately a simpler solution than a single tank option which may require buffer tanks and additional controls to restrict flow elsewhere in the process.

Myth 3: Pasteurization is harder with digestate

Pasteurization can be used on a wide variety of liquid and semi-liquid materials. HRS Batch Sludge Pasteurizers are designed to work effectively with the specific characteristics of digestate, such as carried solids. There are solutions for almost any material. HRS innovations such as the use of corrugated tube heat exchangers means that we can deal with anything from viscous fluids requiring gentle handling or with low rates of heat transfer, to complex mixtures, such as digestate, which would otherwise foul the heat exchanger reducing thermal efficiency and requiring regular cleaning and maintenance.

Myth 4: Pasteurization requires a lot of energy

The amount of energy required to pasteurize a material to 158°F for 1 hour (in line with PAS110) will depend on the starting temperature. Typically this type of treatment of post-digester product will require around 41 kW of energy for each tonne to raise the temperature of the digestate. Traditional single tank pasteurization units simply dump this heat afterwards, meaning they are incredibly wasteful and inefficient.

HRS heat exchangers recapture the heat and use it again, making them up to 70% more efficient than traditional single tank ‘heat jacket’ type pasteurization systems.

Myth 5: Pasteurization slows down the overall process

A well designed pasteurization system should not slow down the overall process. By using three tanks, the HRS system allows one batch of digestate to be treated while one is emptying and one filling, ensuring that pasteurization does not slow down overall throughput.

Myth 6: Pasteurization equipment is high maintenance

The use of corrugated tubes, together with cleaning regime minimizes the amount of fouling and therefore the amount of cleaning necessary to maintain the efficiency of HRS pasteurization systems. In addition, the tubes are designed to be easily accessed for cleaning, inspection or replacement if required.

Myth 7: You must pasteurize the digestate to meet PAS110

Under PAS110, there are several specific exemptions to the requirement for a pasteurization step. These include:

- ‘Digested materials made only from manure, unprocessed crops, processed crops, crop residues, glycerol, and/or used animal bedding that arise within the producer’s premises or holding and that are used entirely within the same premises or holding’;

- ‘Manure, unprocessed crops, processed crops, crop residues, glycerol, and/or used animal bedding that arises within the producer’s premises or holding, if such input materials are co-digested with pasteurized biodegradable materials / wastes from any source(s) outside the producer’s premises or holding’ provided that ‘all the digested material being used within the producer’s premises or holding, irrespective of whether it is part of a farming / horticultural / forestry co-operative.

There is also an exemption from pasteurization for ‘specific input materials that arise within the producer’s premises or holding, which are co-digested with pasteurized biodegradable materials/wastes from outside the producer’s premises or holding, provided that the digested material is used entirely within the producer’s premises or holding’.

In most other cases there is a requirement to pasteurize feedstocks or digestate for at least one hour at 158°F. However PAS110 does provide some specific exemptions. For example, if all feedstock treated by the plant (excluding any products covered by Animal By-Product or ABP regulation) have come from food or drink manufacturing processes which have subjected them to an equivalent level of pasteurization (determined by Pasteurization Units, PU), then further pasteurization may not be required.

Myth 8: You must pasteurize at 158°F to meet PAS110

This ‘myth’ is basically true for most operators, however, other pasteurization regimes (such as treating at lower temperatures for longer) may be approved provided that they can be validated and shown to provide an equivalent standard of pasteurization. Most studies on pasteurization show a linear relationship between temperature and time (i.e. the higher the temperature, the shorter the treatment time required), but this relationship is not consistent for all pathogens and expert advice and full scientific testing must always be carried out before committing to any system.

It is interesting to note that work by WRAP (A consideration of the PAS110:2010 pasteurization requirements, and possible alternatives) points out that a pasteurization step of 158°F for one hour is sufficient to inactivate most of the crop pathogens tested. In fact some, such as certain species of Phytophthora and Fusarium are inactivated within one hour at 135°F, but others, like Spongospora Subterranean are more persistent and viable cells can remain even after such pasteurization. However, these are rendered inactive by the mesophilic temperatures encountered during anaerobic digestion.

Hopefully it can be seen from the above that adding a pasteurization step before or after digestion does not need to be overly onerous. Certainly with the correct choice of equipment pasteurization does not need to have a negative effect on plant throughput, efficiency or operating costs and a well-designed system incorporating heat regeneration and corrugated tubes should enhance the overall facility, helping to add value and flexibility to the final digestate.