Preventing product contamination with double tube-plate heat exchangers

Ensuring product safety is the number one priority for any producer of pharmaceutical products, and a key aspect of this is avoiding contamination during production. Design and construction plays a key role in achieving this, and the heat exchangers used for processes such as pasteurization and sterilization are no exception.

There are three main elements to preventing contamination occurring in tubular heat exchangers: production quality, system design, and system maintenance. The quality of materials (such as the use of stainless steel), and the quality of construction (precise welding and joints) are both important.

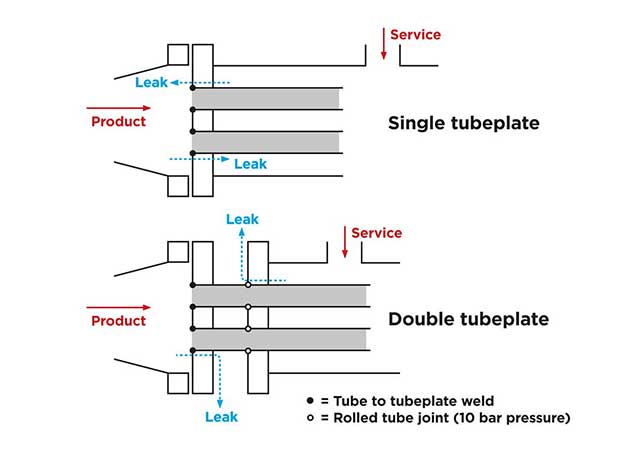

The type of heat exchanger and its design capacity determines the number of tubes, and at some point during the design process, these tubes need to be supported and attached to the body of the heat exchanger – usually at the ends. This tube-plate (sometimes known as the tube sheet) not only supports the tubes, but usually provides a barrier between the product and service fluid.

There are two main methods to prevent cross contamination between the product and the service medium (heating or cooling) due to leakage in tubular heat exchangers. The first is to maintain a positive pressure difference between the product and the service fluid, so that should a leak occur, the product will always flow into the service fluid rather than vice-versa.

The second option is to introduce a physical separation between two different tube-plates; one for the product and one for the service fluid. This means that in the event of a leak from either the service fluid or the product, the material flows into a safety container or other vessel and no mixing of the two materials is possible. Because this option relies on a physical barrier, no additional systems are required, making construction, operation and maintenance of the heat exchanger much simpler.

HRS Heat Exchangers uses the double tube-plate system where contamination needs to be prevented, and double tube-plates are included as standard on our SP Series of pharmaceutical heat exchangers. The double tube-plate system is also used for food production situations, and is standard with our SH and SI Series of multitube heat exchangers, as well as the double tube DTA Series.

The gap between the two tube-plates depends on a number of factors but can be effective at just 3mm wide. The gap may be shrouded (with appropriate drain or inspection ports) or left open.

It is also important to regularly clean, inspect and maintain heat exchanger equipment in line with manufacturer’s recommendations. Regular cleaning will ensure that drain holes etc. operate correctly in the event of a leak, while maintenance and cleaning will reduce the risk of leaks occurring and provide an opportunity for any repairs.