HRS BP Series vs Other Pumping Technology

HRS BP Series Piston Pump vs. Progressive Cavity Pumps

Pumping inside a helical pump, progressive cavity pump or mono pump is based on a rotor and a stator. The rotor has a helical shape that turns inside a stator made of elastic material. The stator contains cavities in order to create chambers of product that will be pushed once the rotor starts turning.

The main disadvantage presented by this kind of pump is the shear stress that the rotor inflicts on the product. Another point that might cause problems is the release of particles of the stator plastic material. Furthermore, the pressure ranges that this kind of pump can perform are very limited due to its working principle.

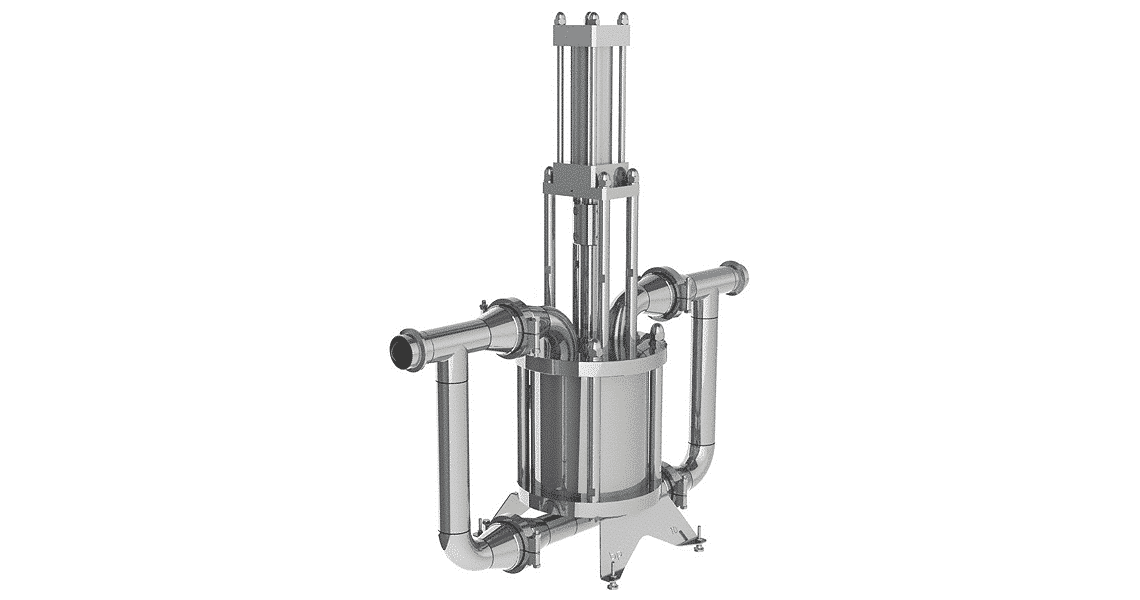

All these drawbacks are overcome with the HRS BP Series piston pump. It avoids shear stress since its piston movement is linear and there are no cavities or areas where the product can be damaged. It also has the bonus of requiring very little maintenance and having a low capital cost.

HRS BP Series Piston Pump vs. Lobe Pump

A lobe pump is a positive displacement rotary pump. Essentially, it is made of two rotors with a lobe shape inside a body which turn in sync without touching themselves.

When the rotors turn, the spaces between the lobe and the body are filled and the product is transported towards the side of impulsion, displacing a fixed volume. Lobe pumps are not suitable for products containing particulates as they produce shear stress.

Since the pieces that perform the displacement are metallic and rotate, the contact between the moving parts performs a weathering that triggers slip at high pressures, decreasing the effectiveness of the pump over time. Lobe pumps also have very high maintenance costs due to the need to narrow tolerances in the precision mechanism formed by the lobes.

The HRS BP Series piston pump does not break particulate products, and is not prone to slipping. Other benefits include minimal maintenance requirements and low costs.

HRS BP Series Piston Pump vs. Peristaltic pump

Peristaltic pumps are volumetric rotary pumps. The rollers attached to the rotor crush a tube, creating uniform chambers that are displaced along the body or track, performing the pumping effect. They are tight pumps, very easily cleaned and the only material in contact with the product is the tube itself. They can work in dry conditions indefinitely and they are very good self-priming, even with viscous products.

However, one weakness of peristaltic pumps is that the product is affected by crushing. There is also a risk of product contamination from the rubbers or plastics used in their construction and they have high maintenance costs and reduced working pressures.

The HRS BP Series piston pump does not crush the particulate products and requires very little maintenance.