Rotary Scraped Surface Heat Exchangers, the optimum solution for Alimentos Profusa

Alimentos Profusa, a Mexican fruit and vegetable processor approached HRS to design an aseptic thermal processing system to treat caramel syrup and fruit bases.

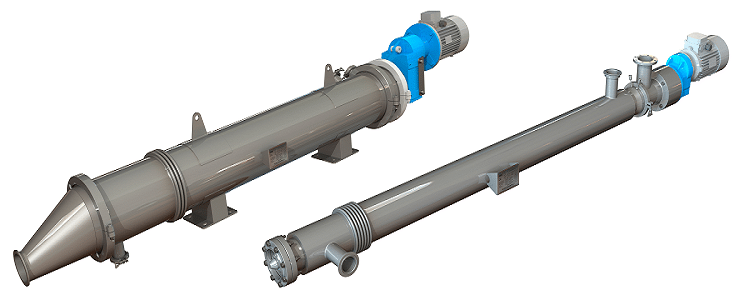

HRS submitted two proposals based upon their scraped surface heat exchanger technologies, the HRS Unicus and R Series. The HRS R series was selected as the optimum solution due to the nature of the non-shear sensitive product.

The R series has been developed for more challenging heat transfer applications ideally suited for both hygienic and industrial applications. The innovative technology processes products with ease, taking full advantage of the high scraper speed which enhances mixing of highly viscous products.

Mounted on a freestanding frame, the customized aseptic system supplied by HRS consists of four HRS R Series scraped surface heat exchangers and a holding section. An individual HRS R3 2m unit will be utilized for the complete heating process, whilst three additional HRS R3 2m heat exchangers will be applied for the cooling processes.

The system also features a flow divert panel to enable the customer to choose to cool with either two or three heat exchangers depending upon the product and associated flow rates. The package incorporates a return heat exchanger for when the temperature has not been reached during aseptic processing and filling.

The bespoke aseptic thermal processing system will ensure the product is heated and cooled to the required temperatures, whilst attaining the stability of the fruit bases and caramel sauce. The system has been designed on the following basis:

- Heating 2 tonnes/hr of fruit bases intended for yogurt and ice cream mixture (with and without particles) from 140ºF to 248ºF, held for 30 seconds – 2 minutes (product dependent) and cooled to 68ºF with chilled water.

- Heating 2 tonnes/hr of caramel syrup sauce from 212ºF to 266ºF with steam at 284ºF, held for 20-30 seconds and cooled to 86ºF with chilled water at 34ºF.

HRS R Series heat exchangers have several unique design features:

- Novel gearbox design achieves continuous scraping action and enhances mixing of highly viscous products while eliminating fouling.

- Each scraper rod is fitted with a helical blade for ease of product propulsion, promoting improved heat transfer rates and a reduction in pressure drop.

- Multi-tube option offered to reduce energy consumption, plant footprint and operating costs.

- Unique sealing system enables removal of individual tubes.

HRS Heat Exchangers has manufactured and delivered the complete aseptic system within 8 weeks from design approval. The system is expected to be put into production during April 2016.