Shanks AD plant achieves PAS 110 certification with HRS pasteurisation system

Challenge

Verifying the quality of digestate in order for it to be sold and applied as an organic agricultural fertiliser to farmers and growers is a complex process with a demanding industry requirement. In order to attain the Publicly Available Specification 110 (PAS 110) certification and maximise the value of digestate, anaerobic digestion (AD) plants must adhere to stringent product quality standards, in addition to high standards for input material and the management system. For international waste-to-product business Shanks Group plc, HRS’s pasteurisation system provided the answer, giving farmers assurance that their digestate is a best-in-class, nutrient rich fertiliser.

Why is PAS 110 important?

As well as setting limits for physical contaminants, such as plastics, the PAS 110 standard requires pasteurisation of the material before or after it is digested.

The HRS Pasteuriser System has also enabled the plant to attain a Certificate of Compliance by Organic Farmers & Growers Ltd. This means that both conventional and organic farmers can use the digestate to provide nutrients and valuable organic matter to their crops.

The HRS 3 Tank Batch Sludge Pasteuriser System also complies with the requirements for treating animal by-products (ABP).

Solution

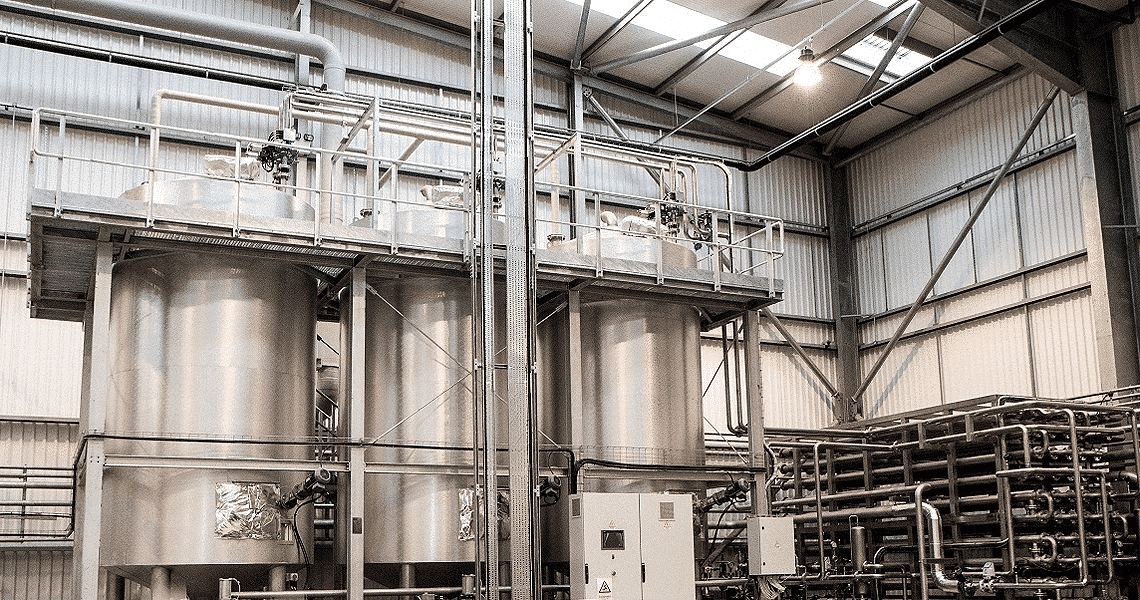

To assist Shanks’ Westcott Park AD facility in Buckinghamshire gain PAS 110 certification, HRS designed and supplied a 3-Tank Batch Sludge Pasteuriser System to pre-pasteurise the food waste feedstock before it is fed into one of the three digester tanks. The system:

- Enables Westcott Park to produce a consistently high quality digestate that can be sold and applied as an agricultural fertiliser.

- Produces a high value organic fertiliser, which can save farming operations as much as 80% in costs compared with bought-in inorganic fertilisers.

- Makes use of heat from the facility’s existing combined heat and power engine that would otherwise be wasted, helping to maximise the overall efficiency of the site.

- Recovers heat from the hot feedstock that has been pasteurised and uses it to pre-warm the feedstock as it enters the pasteuriser system.

Results

Since installing the 3-Tank Batch Sludge Pasteuriser System, Shanks Westcott Park facility has the capacity to:

- Process more than 48,000 tonnes of food waste from varied sources, including the retail and catering sectors, annually.

- Supply the National Grid with enough electricity to power 6,000 homes.

- Save 70% in energy on the site through the recovery of heat from hot feedstock.

Testimonies

“We chose this HRS system because they offered a complete pasteurisation solution – we wanted the tanks, pumps, control system, control logic and everything built into that. HRS designed the facility as a standalone solution.”

Ray Nattrass, Head of Process Design & Engineering at Shanks Waste Management

“I am delighted that our Westcott Park AD facility has achieved this quality standard for our digestate product. By achieving PAS 110, we can assure our customers that our nutrient-rich digestate is recognised as best-in-class. By deploying the digestate back to land we are making more from waste and enhancing our position in the market as a leading waste-to-product company.”

Peter Eglinton, Managing Director of Shanks’ Municipal Division