Multinational food producer reaps benefits of HRS corrugated heat exchanger

Challenges

A food ingredients plant in the northern Malaysian province of Seberang Perai, in the state of Penang, owned by a major multinational food producer, had a history of using smooth-tube heat exchangers for a range of cooling, heating and condensation. However, despite reservations about switching to corrugated tube exchangers, the client wanted to increase energy efficiency, reduce maintenance and cleaning requirements, and lower operational costs.

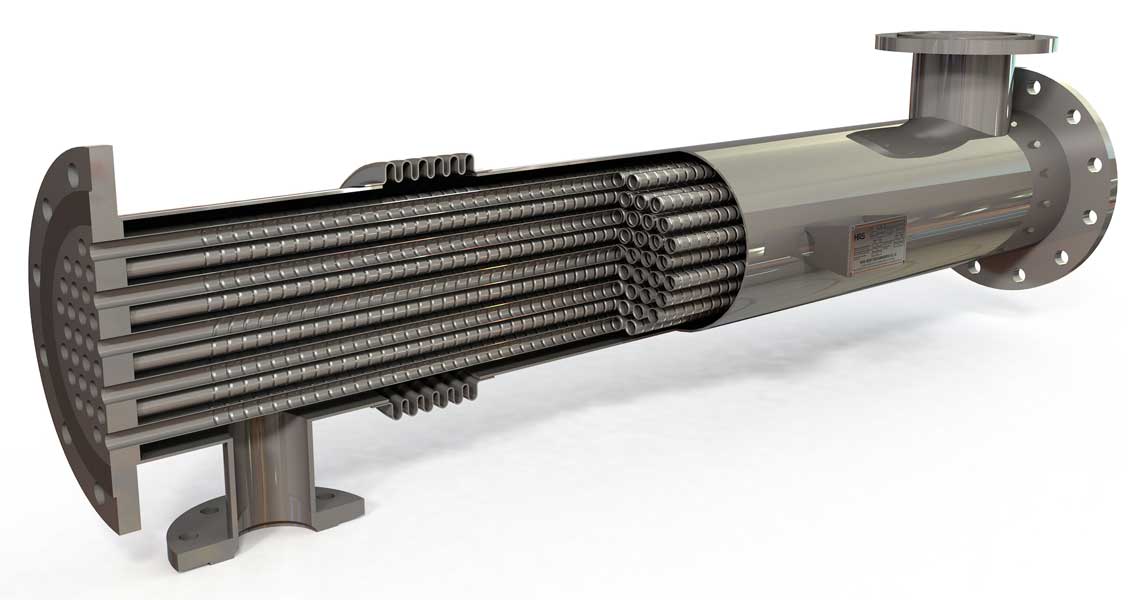

HRS K Series Multitube Heat Exchangers

The HRS K Series is a stainless steel shell and tube heat exchanger for industrial use, particularly steam-to-water applications and where materials have low to medium viscosities. The product flows through the interior tubes and the service fluid flows through the surrounding shell.

HRS corrugation technology means that heat transfer and efficiency are increased over standard smooth tube heat exchangers. In addition, effects of fouling are minimised.

Expansion bellows are fitted to absorb the differential expansion between the shell and the inner tubes and multiple units can be interconnected for larger applications. Options include frame mounting, insulation and stainless steel cladding.

Solution

A HRS K Series heat exchanger was ordered to replace an existing smooth tube unit on a line producing powdered food emulsifier. The corrugated tube creates turbulence in order to break down any fouling layers as they form, reducing cleaning requirements which was one of the client’s main considerations.

The new K Series exchanger uses steam to heat 1,300 kg/hr of fatty acid esters from 90°C to 235°C and has been designed to withstand up to 50 bar(g) of steam pressure. It has been configured as a TEMA BEU-type with a removable tube bundle in a U-configuration to assist cleaning and maintenance, which was an issue with the previous smooth-tube BEM-type unit with fixed tubes.

HRS delivered the unit in May 2018. It was fully commissioned in September last year and has been operating without any issues ever since. Current steam consumption is, resulting in financial savings and reduced energy use for the business.

Results

- Reduced stem use: Current steam use is around 310 kg/hr – significantly less than was previously used for the process.

- Continued production of high quality enzymes and bioproducts for food manufactures

- Reduced cleaning and maintenance

Testimonies

“From the initial discussion which began two years ago, it is great to see that a year of successful operation has convinced our client of the benefits of HRS’s corrugated tube technology. They are seeing real benefits in terms of running costs and energy use and are now looking at replacing additional smooth-tube units to increase these benefits across their business.” Remus Lim, HRS General Manager, Malaysia “The unit is very robust and I’m pleased with its performance. It has certainly reduced our steam consumption.” Client spokesperson