HRS Unicus Series: gentle processing of high fouling products

Heat exchangers are widely used across a range of industries, including food manufacturing, chemical processing, water treatment and renewable energy production. As well as basic heating and cooling, they are used for a wide range of other processes including pasteurisation, sterilization, crystallisation and evaporation. With so many uses, and an almost infinite number of materials which can be treated, it is unsurprising that many substances cause issues for simple plate and tubular heat exchangers. One way to overcome the challenges presented by complex mixtures, particulates or viscous fluids is to use a scraped surface heat exchanger, such as the patented HRS Unicus Series.

The Unicus from HRS Heat Exchangers has been specifically designed to provide unrivalled heat transfer with a wide range of difficult materials across a range of industries, particularly those which have a high fouling potential (therefore limiting heat transfer), but which at the same time need delicate handling to preserve fragile product integrity. A process of continual improvement means that Unicus heat exchangers are available with a wide range of scraper types, providing even more choice for applications from food pasteurisation to biomass pre-treatment.

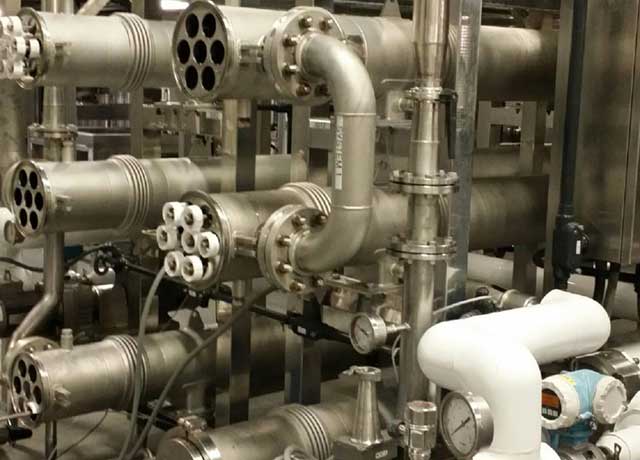

The Unicus Series, which is ideal for industrial and hygienic applications, is based on traditional shell and tube heat exchangers, with the addition of a patented stainless steel scraping mechanism which is hydraulically moved back and forth within each interior tube. This movement performs two key functions. Firstly, it minimises potential fouling of the product by keeping the tube wall clean. Secondly, the movement creates turbulence within the material. Both of these actions help to increase heat transfer rates and together, they create a highly efficient heat transfer process ideal for viscous and high fouling materials.

Another benefit is the fact that the separate hydraulic action means that the speed of the scrapers (which are available in a number of different designs) is highly controllable and can be optimised for the product being processed. This means that materials which are susceptible to shear stress or pressure damage can be handled gently to prevent such damage while still providing high levels of heat transfer.

Matt Hale, International Sales & Marketing Director at HRS Heat Exchangers, comments: “The HRS Unicus series has proved particularly useful in handling viscous food products where texture and consistency are important attributes. For example, a client was producing pizza sauce which sheared when subjected to too much pressure, making it unsuitable for the end use – it literarily wouldn’t stay on the pizza. The Unicus means that effective heat transfer can be carried out at low pressure overcoming such problems.”

Each Unicus heat exchanger consists of three elements: a hydraulic cylinder and power pack, a separation chamber to ensure hygiene and preserve product separation from the motor, and the heat exchanger itself. In smaller units a pneumatic cylinder can be supplied instead of a hydraulic unit. The heat exchanger consists of a number of tubes (depending on the specification), each of which contains a stainless steel rod to which the appropriate scraping elements are fitted. Using a range of materials including Teflon and PEEK (Polyarylethe-retherketone), these provide different internal geometry setups according to the application; such as 120° scrapers for large particulates and 360° scrapers for viscous fluids without particulates.

The Unicus Series is scalable according to need, simply by increasing the shell diameter and adding more interior tubes as required, from one tube up to 80. A key feature of the unit is the specially designed seals which separate the inner tube from the separation chamber. With the exact seal design depending on the product application, this prevents leakage of the product and ensures internal and external hygiene. A standard range of models for food processing or industrial applications provide heat transfer areas from 0.7 to 10 m², while larger models up to 120 m² can be made according to specific requirements.

The prevention of fouling can be particularly important for evaporation applications, so HRS Heat Exchangers have developed a special version of the Unicus for industrial evaporation systems where volume reduction is vital. The scraping action keeps the heat transfer surfaces clean, meaning that Unicus evaporators can concentrate materials to a level beyond that typically achieved with traditional technologies. The Unicus evaporators can be used in either multi-effect setup or in combination with mechanical vapor recompression.

“Not only does the scraping action improve heat transfer, but it also allows continuous operation in many situations, increasing plant productivity,” adds Matt. “Over many years we have developed the design of the Unicus so that we have versions and specifications for use in most industries.”