Willen Biogas: Maximising the Value of their Digestate

Williams & Co. is a Middlesex-based farming company which grows 2,000 acres of arable crops and speciality herbs near Enfield. When it formed Willen Biogas in 2008 in order to investigate the potential of a biogas plant on the farm, it was determined to maximise the value of all the outputs from its plant, including the gas, the heat, and the digestate.

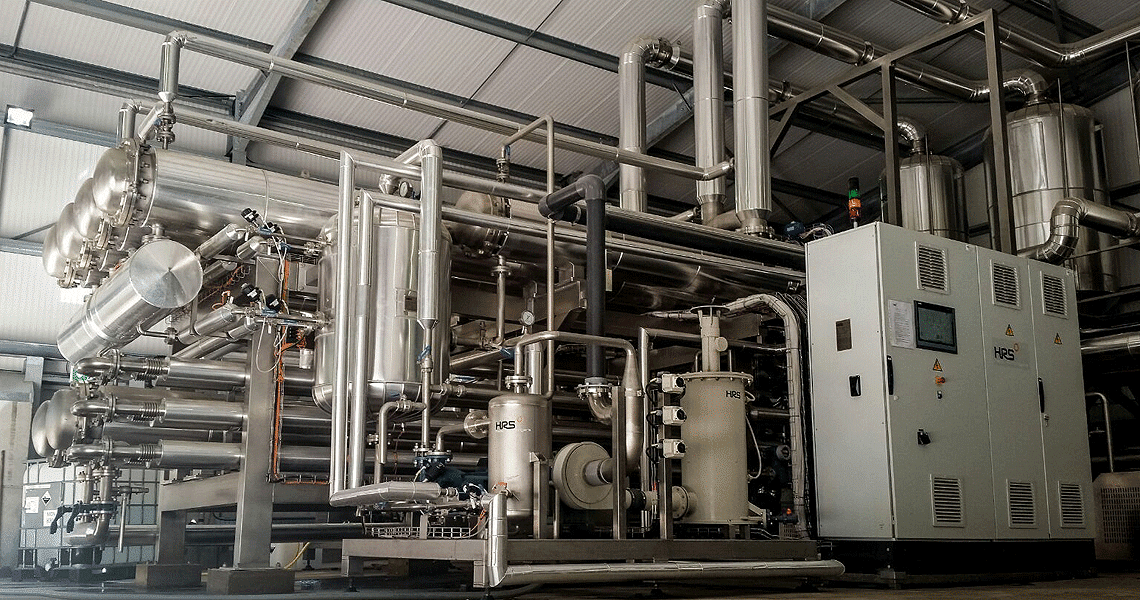

Early on in the development process for the 1.5 MW plant which handles 25,000 tonnes of food waste a year, Willen Biogas approached HRS Heat Exchangers to see how the HRS Digestate Concentration System (DCS) could reduce digestate volumes and improve the quality of this valuable organic fertiliser.

With the farm located just 13 miles north of the centre of London on heavy London clay soil, it became clear that digestate from the AD process could help the farm reduce the cost of cultivations, minimise its use of manmade fertilisers, reduce its environmental impact, and deliver financial savings. Digestate production was one of the main drivers for the plant but with 41,000 tonnes of liquid digestate being generated each year, Willen needed to reduce the liquid fraction without losing any nutrients.

As well as helping to minimise the amount of application traffic travelling across the farmland, it also reduced the amount of storage needed, so that the digestate can be applied at the optimum time for the crop and in compliance with Nitrate Vulnerable Zone (NVZ) requirements. Overall, reducing the volume of digestate helps reduce the costs associated with transporting, storing and applying large volumes of liquid digestate.

The HRS Digestate Concentration System (DCS) removes up to 80% of the water contained in the liquid fraction and concentrates it to 20% dry solids while, at the same time, maximising the nutrient content. Heating the digestate with surplus water from the plant’s CHP engine, the DCS has reduced the liquid fraction of Willen’s digestate by 60% (from 50,000m3 to 20,000m3 per year), making digestate handling, storage, transport and application not only easier for Willen Biogas but less costly, too.

The first part of the DCS process involves heating the liquid digestate in heat exchangers; minimal additional water and energy is required, as the surplus water from the plant’s CHP engine is used as the heating media. The steam produced from this first cycle is then used as the heating media for the second effect, whereby the process is repeated with further cycles. The number of effects is determined by the level of dry solids required, and the amount of spare heat available, up to a maximum of four cycles. After the final effect, the steam is condensed back into water and is used to displace mains water used in the front end of the digester; a completely closed loop system. The DCS is virtually self-sufficient – minimal energy or water is bought in, nothing is wasted, and the surplus energy from the CHP is re-used up to four times.

Using patented technology designed and manufactured by HRS Heat Exchangers, the DCS is a superior and energy-efficient way of concentrating digestate. It is four times more efficient than conventional digestate drying technology and is enabling D. Williams & Co to displace 1,093 tonnes of artificial fertiliser each year, including some 688 tonnes of ammonium nitrate.

Another benefit of the DCS is odour control, which actually helps increase the nutrient content of the digestate. The high temperatures needed to concentrate digestate can cause the release of ammonia, largely responsible for the odours associated with digestate. However, the DCS overcomes this by acid-dosing the digestate with sulphuric acid, thereby decreasing the pH levels. This turns the ammonia into ammonium sulphate, which is not only less odorous, but is also an ideal nutrient.

| Nutrient content of Willen Biogas’ digestate (kg/m3) | ||

| Before treatment with the DCS | After treatment with the DCS | |

| Nitrogen (N) | 5 | 12.5 |

| Phosphorus (P) | 2 | 5 |

| Potassium (K) | 2.5 | 6.25 |

| At Willen the nutrient content has been increased by 150% by the DCS. | ||

As well as creating a more concentrated, richer fertiliser, the DCS delivers the following additional benefits for Willen Biogas:

- By reducing the liquid fraction by 60%, transport, water and storage costs have been cut, reducing operational overheads significantly.

- The amount of traffic going across the farmland has been significantly reduced (down from 2174 tanker movements per year to just 870).

- Unlike conventional digestate dryers – which use a lot of power to create a small amount of product – the DCS is extremely energy efficient; surplus heat from the CHP engine is reused up to four times over, and the wastewater is then used to displace mains water in the front end of the digester.

- Minimal additional energy and water is required, and none is wasted.

- Willen Biogas can claim RHI payments for using their heat within the DCS, increasing their profit margins further.

- As a plug-and-play, fully automated system, the DCS is completely flexible and has been uniquely tailored to suit the needs of Willen Biogas.

Adrian Williams, Director of Willen Biogas and Partner in D. Williams & Co, comments:

“We are producing approximately 41,000 tonnes of liquid digestate each year, which is full of nutrients for the farm, but we wanted to minimise the amount of traffic going across the farm land, and the amount of storage needed. The DCS system from HRS helps us to have more efficient spreading windows for the farm, making digestate handling a lot more manageable. We enjoy all the nutrient benefits with less volume of digestate to apply to the land that we farm.”

Matt Hale, International Sales Manager for HRS Heat Exchangers, adds:

“We are delighted to have worked closely with Willen Biogas to aid the management of their digestate and improve their overall process efficiency. Our solution integrates fully with the rest of the plant and helps to maximise output by reusing hot water which would otherwise be wasted. Using quality digestate on the farm is an integral part of this project and the DCS has been specifically designed to reduce the volume of material to be stored and applied, while maintaining its value as an organic fertiliser. Not only will this deliver considerable financial savings to the farming business, it will also help it to further reduce its carbon footprint.”