Acrylamide Reduction in Industrial Food

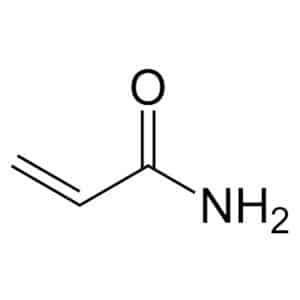

The World Health Organisation (WHO) has established a maximum level for drinking water of 0.5 mg/litre and European legislation on migration of chemical substances in plastic packages lays down a limit of 10µg/kg. Acrylamide is included in the list of Extremely Hazardous Substances of the United States Occupational Safety and Health Administration as it is a neurotoxin, a genotoxin, it is carcinogenic and reactive.

In April 2002 the Swedish National Food Administration reported on high levels of acrylamide in various foods frequently consumed in the western diet. As a result of the Swedish studies other countries initiated their own investigations, amongst them Holland, where they discovered products with levels of acrylamide between 30 and 3100 µg/kg. The foods with the highest levels of acrylamide were potato crisps, overcooked potato chips, other snacks and gingerbread.

Later studies found that the acrylamide was formed spontaneously during the cooking or thermal treatment processes from the Maillard reaction. Acrylamide forms when foods, principally those with a high starch content, are baked or fried at high temperatures.

In general, acrylamide is formed naturally when food is cooked or processed, such as baking, frying or roasting. It is not only an industrial problem, home cooked foods can also form acrylamide in abundance if we roast or fry foods excessively. Acrylamide forms at temperatures above 120°C. According to some studies, the level of acrylamide produced depends on:

- Temperature

- Cooking time

- Levels of asparagine (proteic amino acid) and reducing sugars present in the cooked food

The Contribution of HRS Heat Exchangers

HRS Heat Exchangers are working to reduce process times and our products and processes are all designed to minimise the time taken for the process. As well as improving the economics of the process by saving energy, reducing processing time also brings benefits to the final organoleptic properties of the foods processed using our machinery and processes.

As an example, the time taken to cook in reactors of 1,000 litres or autoclaves can be hours, while HRS equipment can produce the same result using the same recipes and quantities in 15 to 20 minutes. It also brings the possibility of continual cooking as opposed to being obliged to cook in batches in a reactor or autoclave.

In some cases our machines can use direct heat recovery in which the recently cooked hot product is cooled by preheating the uncooked incoming ingredients, bringing a significant saving in energy. In the case of the autoclave or reactor all heat used in the process is lost and sometimes they even require additional energy to cool down.

As a general rule, whether cooking at home or an industrial scale, burning of food should be avoided. Various products should be cooked until they have a golden- yellow colour, as opposed to a golden-brown colour.