Resources

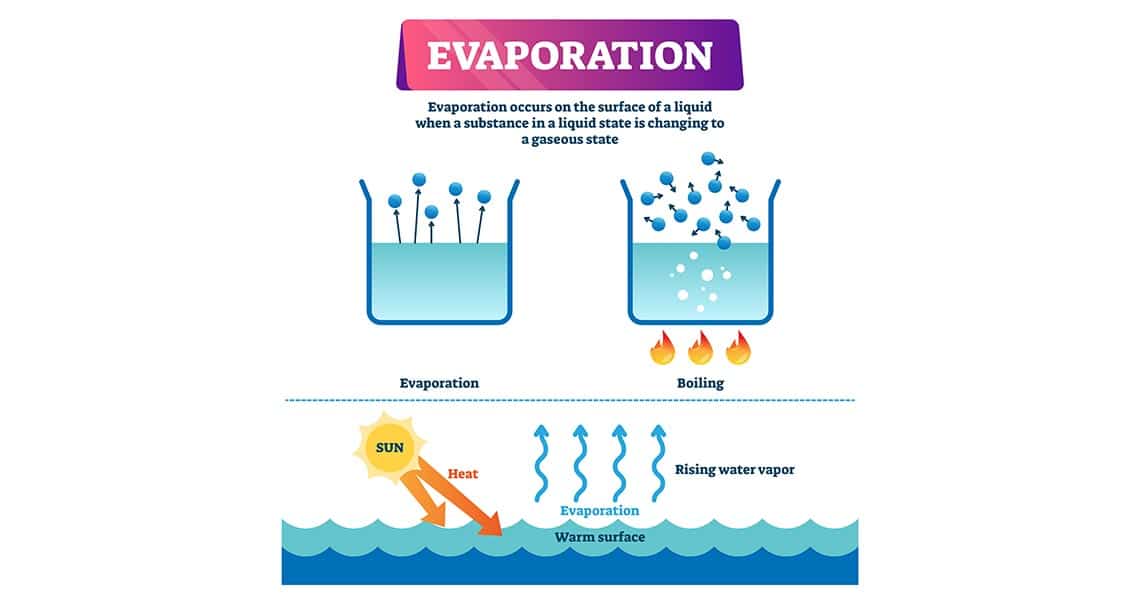

Best Practice for Evaporation Processes

Evaporation is an important industrial process, used for concentrating solutions in a range of sectors including water and waste treatment, manufacturing and even the food and pharmaceutical sectors.

Read MoreUnderstanding Digestate

WHAT IS DIGESTATE? Digestate is the material that remaining after the anaerobic digestion of a biodegradable feedstock such as wastewater sludge, food waste, animal waste or other organic waste products. Anaerobic Digestion (AD) produces two main …

Read MoreWhat is a Heat Exchanger?

Heat exchangers are used in both heating and cooling processes to transfer heat expended from one process or place for use in another. They enable the thermal energy from a liquid or gas to pass …

Read MoreTop tips for specific types of heat exchanger fouling

When handling difficult materials, such as sewage sludge or corrosive chemicals, heat exchangers can be particularly susceptible to fouling. Having previously looked at the general issue and different types of fouling which may be experienced, …

Read MoreISO 9001 Quality Assurance Accreditation

QUALITY POLICY The management team of HRS Heat Exchangers (HRS) is committed and responsible for establishing, implementing and maintaining the Quality Management System to ensure customer satisfaction, employee participation and continuous company development. Every HRS …

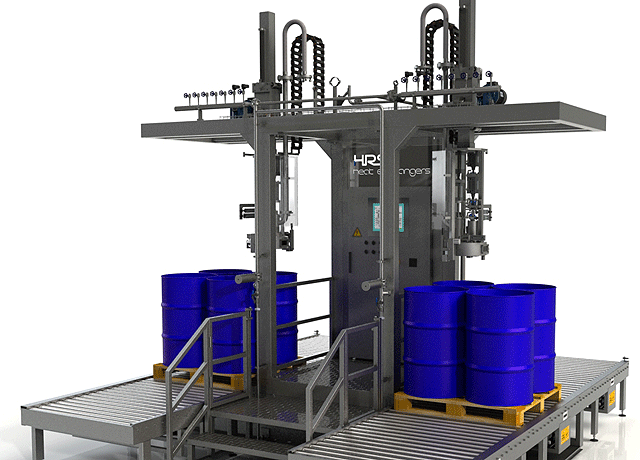

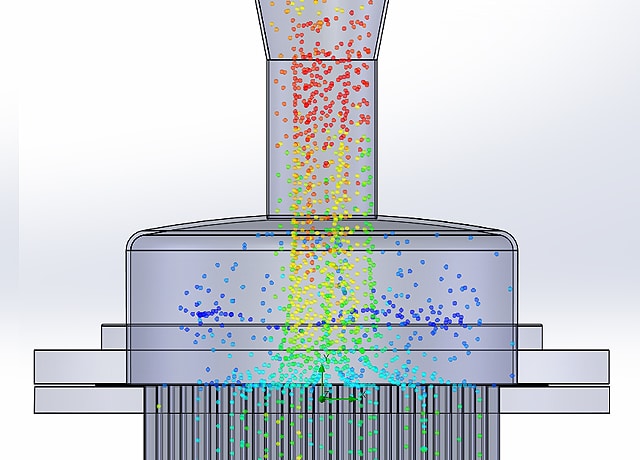

Read MoreComputational Fluid Dynamics in Heat Exchanger Design and Analysis

Recently we were approached by a customer that had several condensers installed which were giving performance problems. The condensers simply did not perform to their capacity. The customer was worried that the problem did not …

Read MorePressure Equipment Directive 2016/68/EU Categorisation

Introduction to 2016/68/EU – Pressure Equipment Directive (Formerly known as Directive 97/23/EC) All equipment with a maximum allowable pressure greater than 0.5 Bar above atmospheric pressure must be assessed in accordance with the European Pressure Equipment …

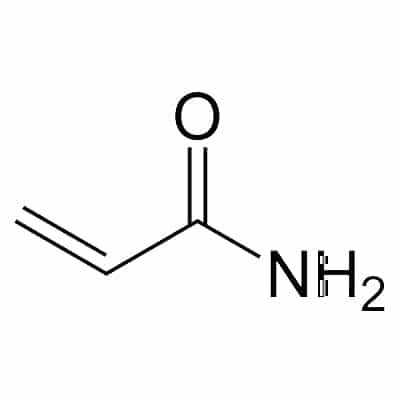

Read MoreAcrylamide Reduction in Industrial Food

Acrylamide, also known as 2-propenamide or acrylic amide, is a chemical substance has a role in making polyacrylamide, which in turn is used in inks, in flocculants for water treatment, in cement production and the …

Read MoreTypes of Packaging for Foods and Beverages

Various types of aseptic packaging have been developed over the years as a result of different demands. This page highlights some of the key steps in the evolution of modern food packaging. Cans Some estimates …

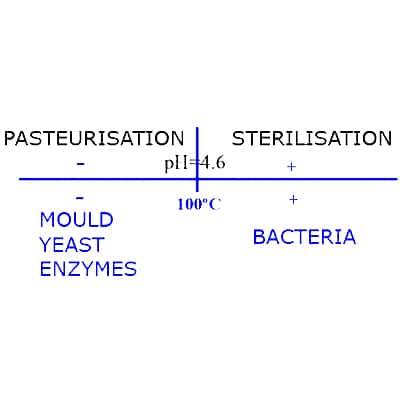

Read MoreThermal Treatment in Food Industry

The thermal treatment of food is necessary in order to: Reduce the microbiological flora present in the food Avoid alterations produced in the food by non-pathogenic micro-organisms Apply the appropriate amount of heating/cooling to each …

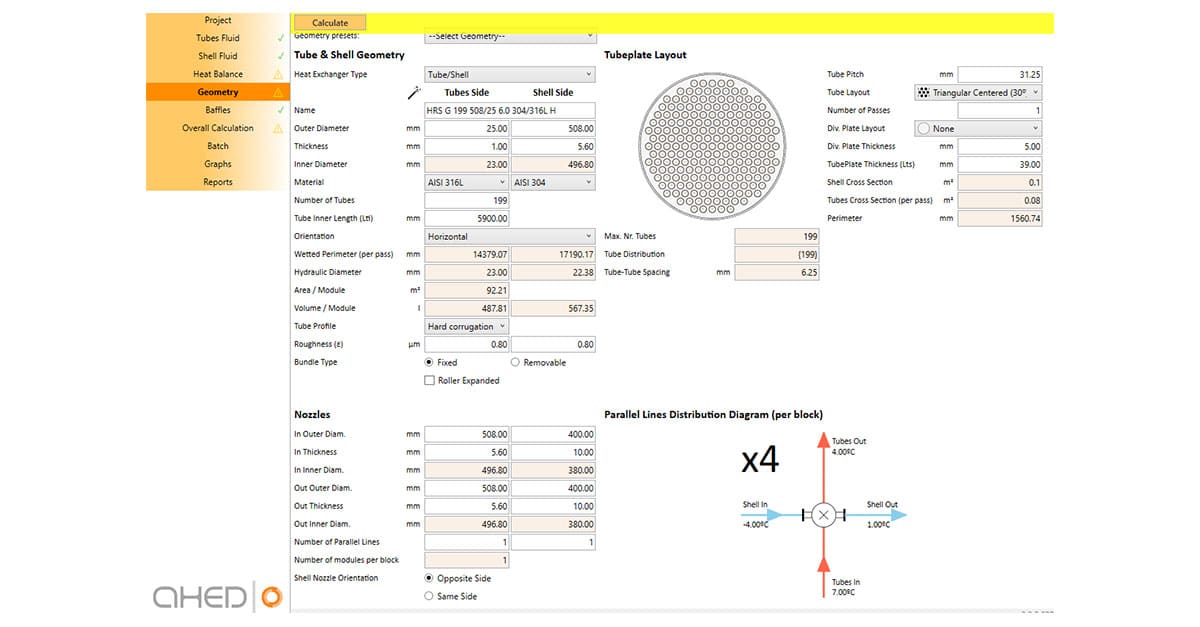

Read MoreHow to Design a Tubular Heat Exchanger

How to Design a Tubular Heat Exchanger At HRS Heat Exchangers we design tubular heat exchangers every day. This section provides an overview of the process. Step 1: Analysing the Application When we first receive …

Read MoreHeat Transfer Fundamentals

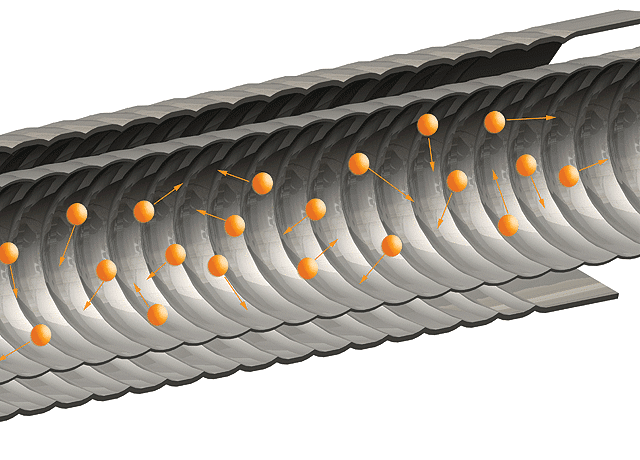

Introduction As noted here, the basic principle of heat transfer is extremely simple, two fluids at different temperatures are placed in contact with a conductive barrier (the tube wall) and heat is transferred from the …

Read MoreFouling Factors in Heat Exchangers

The fouling factors to be used in the design of heat exchangers are normally specified by the client based on their experience of running the plant or process. If uncontrolled, levels of fouling can negate …

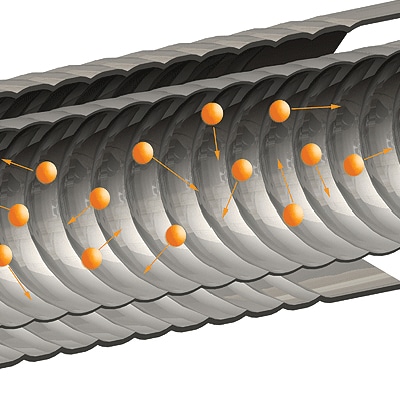

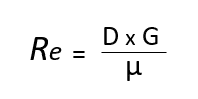

Read MoreComparison of Laminar and Turbulent Flow

Heat Transfer Flow Regimes One of the important factors controlling heat transfer is the resistance to heat flow through the various “layers” that form the barrier between the two fluids. The driving force for heat transfer …

Read More