HRS Received Order for MVR Evaporation System for Life Desirows Consortium

HRS Heat Exchangers has been awarded the order for design, manufacture and installation of a Mechanical Vapor Recompression Evaporation System for the Life Desirows consortium.

Life Desirows

Life Desirows is an EU funded research project that studies a process that offers a circular economy solution for the brines that are generated from using reverse osmosis (RO) technology for creating irrigation water. If not treated properly, these brines contribute to the nitrates being discharged into the water course. The deterioration of the water quality has had a negative effect on the tourism industry, which together with agriculture is the main economic driver in the region of Murcia.

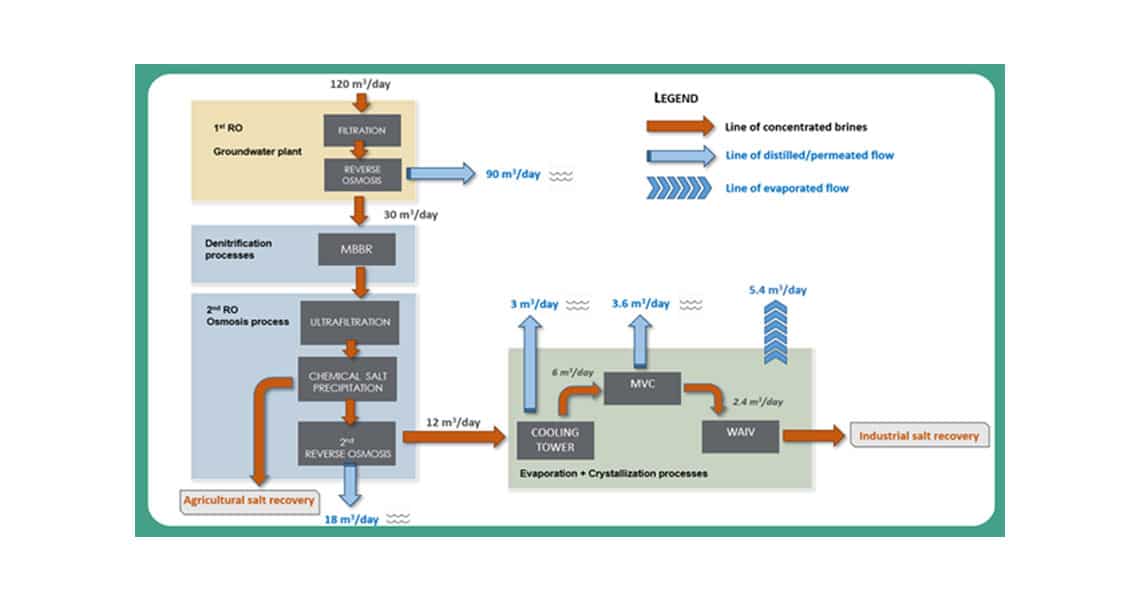

An urgent solution was required, several local companies have teamed up together with the University of Cartagena to investigate a technological solution for the agricultural brines that endanger the Mar Menor and Mediterranean area: The process developed will remove nutrients and separate different salts from the brine that can be used as fertilisers. First, a double RO process generates a second RO brine which goes through a denitrification and chemical precipitation process for nutrient removal and salt separation. The RO process is followed by a thermal concentration process using a Cooling Tower and Mechanical Vapour Compression that concentrate the final brine to its final saturation condition. The final step is the removal of the precipitated salts, by Wind-Aided Intensified Evaporation, that can have applications in other industries. The result is known as a Zero-Liquid- Discharge solution: the environmentally unfriendly brine is converted into clean water for irrigation, fertiliser and salts for industry. When applied the Life Desirows process prevents the leakage of unwanted substances from agriculture into the water course. All processes are supplied by renewable electrical energy.

HRS Heat exchanger MVR evaporation

The solution that HRS is providing the consortium is a forced recirculation evaporator driven by mechanical vapor recompression (MVR). MVR evaporation is one of the most economical ways of concentrating waste streams and doesn’t require any thermal energy source. The electrical energy needed for driving the MVR compressor comes from a renewable energy source: photovoltaic solar panels. The use of renewable energy was one of the pillars of the Life Desirows project.

The HRS corrugated tube evaporation module is ideal for the application of the brine concentration. Corrugated tube generates extra product turbulence, giving enhanced heat transfer and also delays the effects of heat exchanger fouling. These features are key when dealing with challenging products such as brines and waste waters.

Tomas Stiebe, one of HRS’s evaporation experts commented: “HRS is delighted to contribute with a technical solution for this environmental challenge. With both our office and manufacturing facility being in the Murcia region, we as locals are aware of the environmental problem suffered in the Mar Menor. Product trials were conducted with the University of Cartagena to investigate the evaporation process and ensue the right choice of technology. HRS have delivered several zero-liquid-discharge systems to customers in Spain, giving us the confidence to solve the concentration part of the Life Desirows system with our corrugated tube MVR evaporator.”