HRS Returns to AUSPACK with Process Line Solutions

HRS Heat Exchangers, Stand F022, AUSPACK 2022, 17-20 May 2022

HRS Heat Exchangers are delighted to be returning to AUSPACK in Melbourne in May where they will showcase how different HRS systems can be combined to provide complete, bespoke packaging and processing solutions.

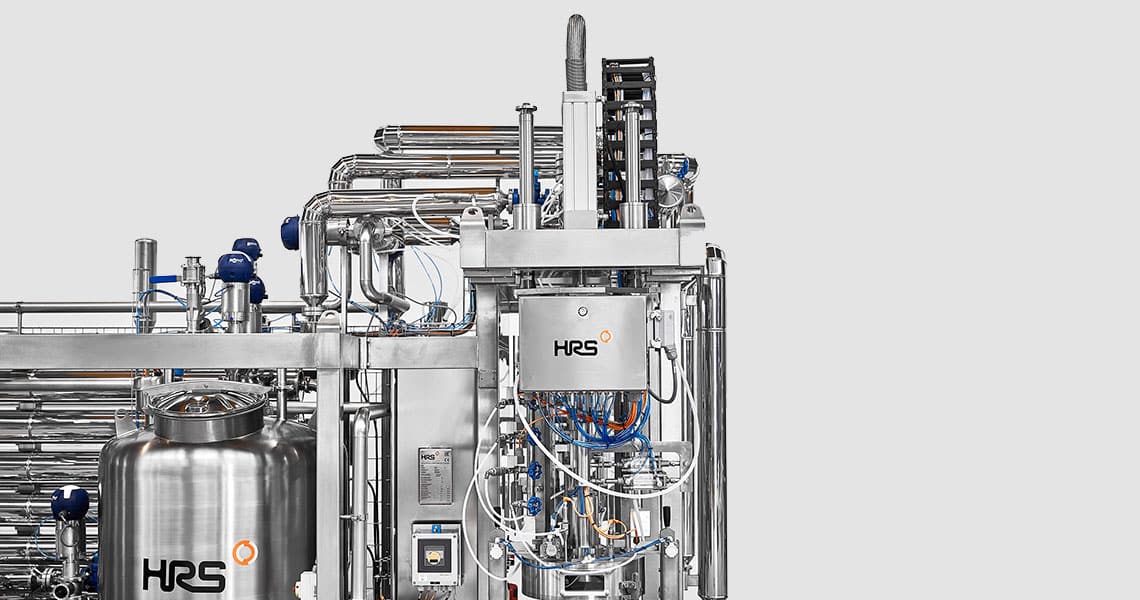

With more than 40 years’ experience in the wide range of sectors, including food, drink, pharmaceutical, environmental, and industrial, HRS has developed a range of proven processing systems including heat exchangers, aseptic fillers, pumps, pasteurisers and sterilisers, ice crushers and re-melters, trial systems, cleaning systems and process skids.

For many situations integrated systems, such as the range of Asepticblock pasteuriser/fillers, will provide a convenient, effective, and cost-efficient solution in a self-contained plug-and-play format. For other more complex products and processes, different HRS equipment can be combined to provide complete processing and packaging lines.

One example is in fruit juice production, where HRS offer solutions to de-pack, crush, and re-melt frozen juice concentrate (I Series), novel heat exchanger solutions to pasteurise the product, as well as the necessary pumps and aseptic filling equipment to complete the production process. Another area where demand is growing rapidly is the ‘plant milk’ sector, and the HRS DSI Steriliser, which uses direct steam injection to rapidly heat the product, is ideal for such use.

HRS is well known for its corrugated and scraped surface heat exchangers which provide energy efficient heat transfer in a small footprint and are particularly suitable for a wide range of food and drink products, waste streams and environmental materials including challenging products such as cream, complex sauces, meat slurry, wastewater and digestate.

To discuss how HRS products and systems can help your processing business, visit Stand F022 at AUSPACK 2022 in Melbourne from 17-20 May 2022.