Increasing Interest In ZLD Driven By Costs And Environment

In 2021 the global market for zero liquid discharge (ZLD) technology was estimated at $1 billion and is forecast to grow at almost 12% over the next ten years¹. The rise is being driven in particular by an increase in adoption of the technology by the food and drink and textile industries as a growing world population puts greater pressure on fresh water supplies.

What is ZLD?

Zero liquid discharge (ZLD) is a liquid waste stream treatment which involves transforming liquid waste streams into clean water (which can be reused) and a minimum volume of solid residues.

A well-designed ZLD system should minimise or even eliminate liquid waste streams, resulting in clean water for reuse or environmentally-friendly discharge, and a solid residue suitable for further processing (often to recover valuable components for use elsewhere) or for safe disposal.

ZLD is being implemented across a wide range of industries, including chemical and petrochemical production, food and drink production, textiles, energy and power, and pharmaceutical manufacturing. These industries are being driven to adopt the technology due to growing environmental awareness of the hazards of toxic wastewater and increasing environmental regulation. In turn this has increased the costs of handling and disposing of such waste streams, and in some cases has made such disposal impossible. As a result, companies are looking for more sustainable alternatives, and ZLD is one of the leading technologies in this area.

ZLD technology has been utilised in various markets around the world, including Europe, Australia, Canada, the Middle East and Mexico, but the biggest markets, and the biggest potential for expansion, can be found in the United States, China and India².

It is wise to choose an evaporation process that optimises energy use, such as:

-

- Multistage evaporation: using the latent heat of the evaporated water as energy source in a next evaporation stage reduces the overall consumption of the boiler to the evaporation plant.

- Thermal Vapor Recompression (TVR): evaporated steam is mixed with boiler steam. The reuse of the evaporate steam reduces the energy demand.

- Mechanical Vapor Recompression (MVR): An MVR compressor (driven by an electrical motor) can be used to compress the evaporated steam, thus increasing its pressure, and use this steam as the energy input for the process. MVR compression is very efficient in terms of energy consumption.

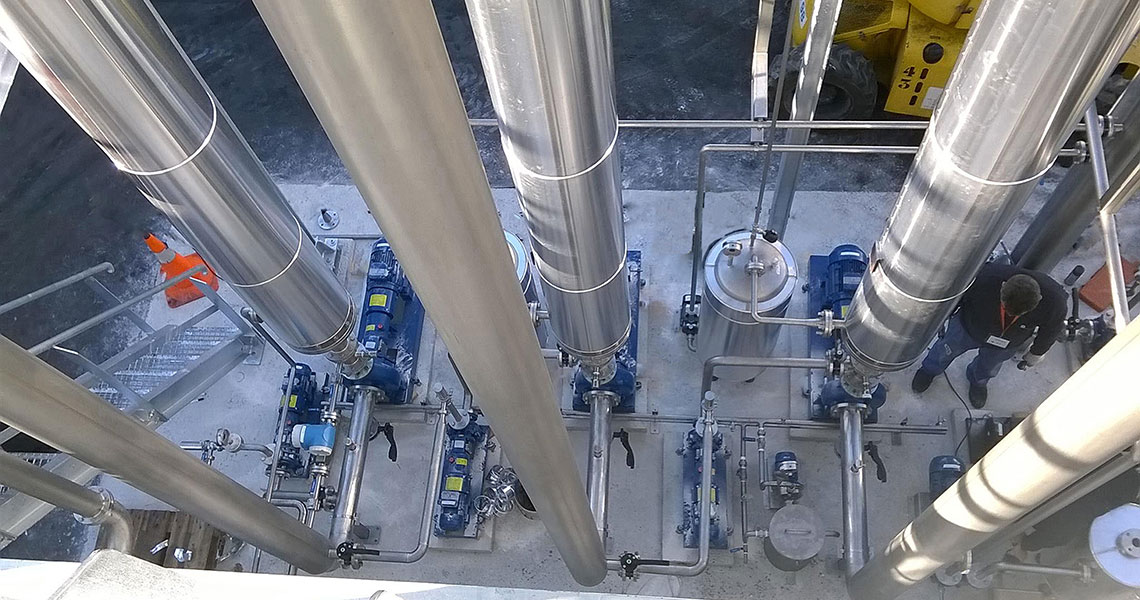

The HRS ZLD solution

Depending on the product to be concentrated, HRS can select from a series of technologies for designing the most optimal ZLD process. Energy optimisation methods (multistage, TVR, MVR) can be combined with several types of heat transfer technologies (plate evaporators, corrugated tube evaporators, scraped surface evaporators). Whatever the technology applied, the overall process can be separated into three steps:

- Evaporation / concentration: The product is concentrated to just below its maximum concentration (saturation). The evaporation plant is usually a multistage evaporator setup.

- Cooling: if the maximum solubility curve is steep (large concentration at high temperature, low concentration at low temperature), the product obtained in step 1 is cooled, provoking immediate precipitation of dissolved solids.

- Crystallisation: Crystallisation / sedimentation of the solids produced in step 2 occurs in specially designed crystallisation tanks. A supernatant layer of concentrated solution remains after this stage and is returned to step 1 for reprocessing.

A typical HRS evaporator / finisher will use Unicus scraped surface evaporators that are self-cleaning and maintain optimal evaporation rates. Typically, our R series scraped surface coolers are used for cooling the saturated brines that are send to the crystallization tanks. The result is an efficient process which can work continuously without requiring scheduled downtime.

Whatever kind of evaporator is employed, heat exchangers have a crucial role to play in ZLD systems in reducing running costs by utilising heat from process water and other existing sources, and also recapturing heat at the end of the process and reusing it to boost the energy efficiency of the overall ZLD system.

² Tong, T. & Elimelech, M. (2016) The Global Rise of Zero Liquid Discharge for Wastewater Management: Drivers, Technologies, and Future Directions in Environmental Science & Technology. Available at https://pubs.acs.org/doi/10.1021/acs.est.6b01000