Spiral or corrugated tube heat exchangers – which is best for wastewater treatment?

Since the first spiral heat exchanger was proposed back in the 19th century, they have become synonymous with the treatment of slurries and wastewater. However, in many situations the performance of a corrugated tube heat exchanger is equal to or better than that of a spiral design. Corrugated tube designs also provide a number of additional advantages in terms of day-to-day operation and maintenance.

Proponents of spiral heat exchangers (sometimes known as shell and coil heat exchangers) cite the following advantages:

1. Good thermal performance, even where the temperature difference between the two materials is small;

2. The spiral design and use of a single channel is claimed to prevent fouling and be ‘self cleaning’

3. Compact design makes them suitable for installations where space and/or access is restricted;

4. The counter-current flow provides an effective way to recover waste heat.

However, given how frequently HRS’ clients choose to replace existing spiral heat exchangers (SHEs) with corrugated tubes, these claims need closer inspection.

There is no doubt that in theory SHEs offer greater thermal efficiency than conventional smooth surface tubular designs due to their large surface area and true counter-current flow. However, this assumes that the barrier between the product and service fluids is kept clean at all times. In practice, fouling frequently occurs, interfering with thermal transfer. Where the heat exchanger is used for sludge-to-sludge applications, this fouling layer can create a double barrier to efficient heat transfer.

The design of SHEs can create turbulent flow inside the exchanger, which is claimed to reduce the likelihood of fouling. The theory is that where blockages start to occur, product flow speeds up; creating a ‘scrubbing’ effect that dislodges the blockage. In our experience this is unlikely in many real world situations, particularly where SHEs are used with sludge. In fact, when you read further into manufacturers’ brochures, ‘self cleaning’ often becomes ‘virtually no fouling and clogging’ – two very different claims.

Manufacturers of SHEs also claim that their units are easy to clean. However, it is not uncommon to have to remove 40-50 bolts just to open the unit. There is also the issue of the expensive bespoke gaskets which are used to seal SHEs, and which need to be replaced each time the cover is refitted. To overcome this some SHE models have hinged covers, which increases the amount of space required for the installation and contradicts claims of SHEs being self-cleaning.

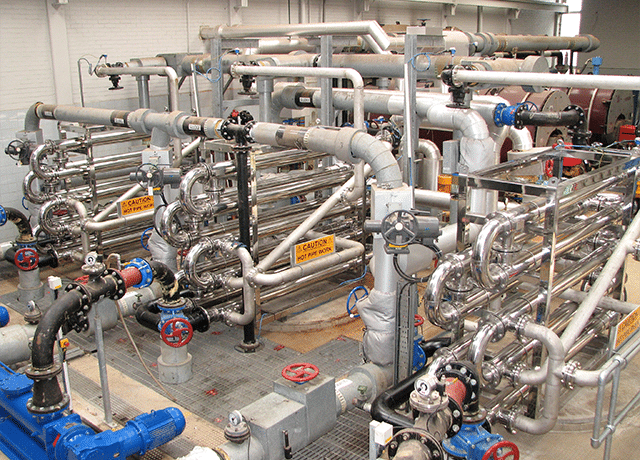

By contrast, the corrugated tubular design of the HRS DTI Series reduces fouling in a number of ways. The tube-in-tube design offers much larger channel than spirals, thereby reducing blockages. The corrugated inner tube also encourages turbulence, which increases heat transfer and reduces fouling – the very reason why HRS uses corrugated tubes. The tubes within the DTI Series are easy to clean and maintain. Removable bends make the tubes very easy to access, and there are no expensive gaskets to replace.

Unlike SHEs, corrugated tube heat exchangers from HRS can easily be removed for inspection, cleaning and maintenance and a variety of flange connections are available. Should the heat exchanger suffer internal damage, the failed section can be easily bypassed by moving the interconnecting bends; a replacement can be manufactured and fitted when it is ready. In contrast, if a spiral is damaged, the complete heat exchanger must be removed to a workshop where many layers have to be cut out to access the point of failure. This is then re-welded and all the cut away sections must be re-welded into place. The cost is significant and downtime is many weeks.

In many situations, we believe that a corrugated tube heat exchanger, like the HRS DTI Series, is the best solution for challenging materials such as sludge. However, in the most extreme cases with a very high fouling risk, it will be necessary to use a scraped-surface heat exchanger such as either the HRS rotating R Series or the patented reciprocating Unicus Series.