Leading processor selects HRS for their efficient aseptic sterilisation plant

HRS Heat Exchangers has provided a leading Spanish fruit and vegetable processor with an aseptic steriliser for a fruit concentrate application.

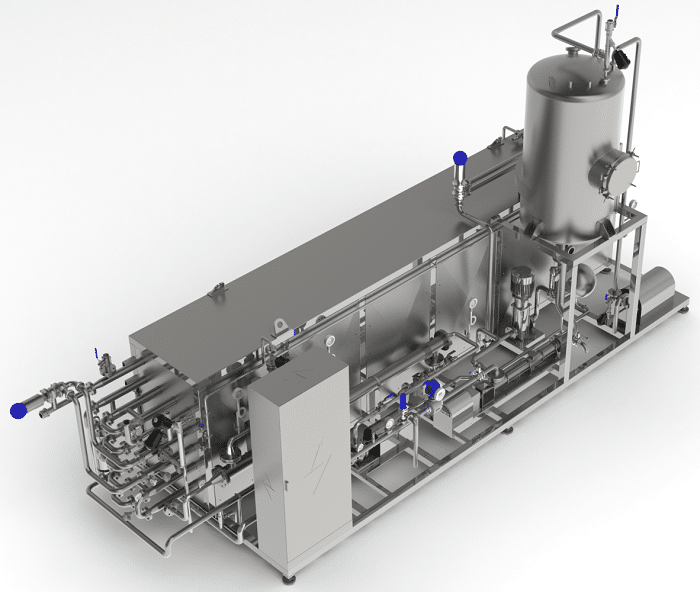

A leader in processing and treatment of seasonal fruits, citric fruits and vegetables, selected HRS for the design, manufacture and installation of the complete sterilisation unit. The plant, which consists of several fully skid mounted process components; will be capable of processing 8000 kg/hr of fruit concentrate.

Annular space corrugated tube heat exchangers form an integral role at the core of the system, namely the HRS AS Series. The AS Series is ideally placed for processing highly viscous products without particles, whereby the product flows through a central annular space, receiving heat treatment from two sides, thus enhancing heat transfer and efficiency. In addition, potential fouling is minimised.

The HRS BP Series piston pump is applied to push the product through the AS Series heat exchangers. The fully hygienic, stainless steel pump is designed specifically for pumping delicate food products, whilst maintaining product integrity. The BP Series is capable of design temperatures of 120°C and fully adaptable for CIP cleaning and working within aseptic processes.

The steriliser is a unique compact setup, operated from a single control panel. An adaptable system which handles with ease and is highly reliable.

The plant is manufactured in compliance with the requirements of the European Pressure Vessel Directive 97/23/EC and the Food & Drugs Administration (FDA & EHDGE).